- Overview

- Product Parameters

- Detailed Photos

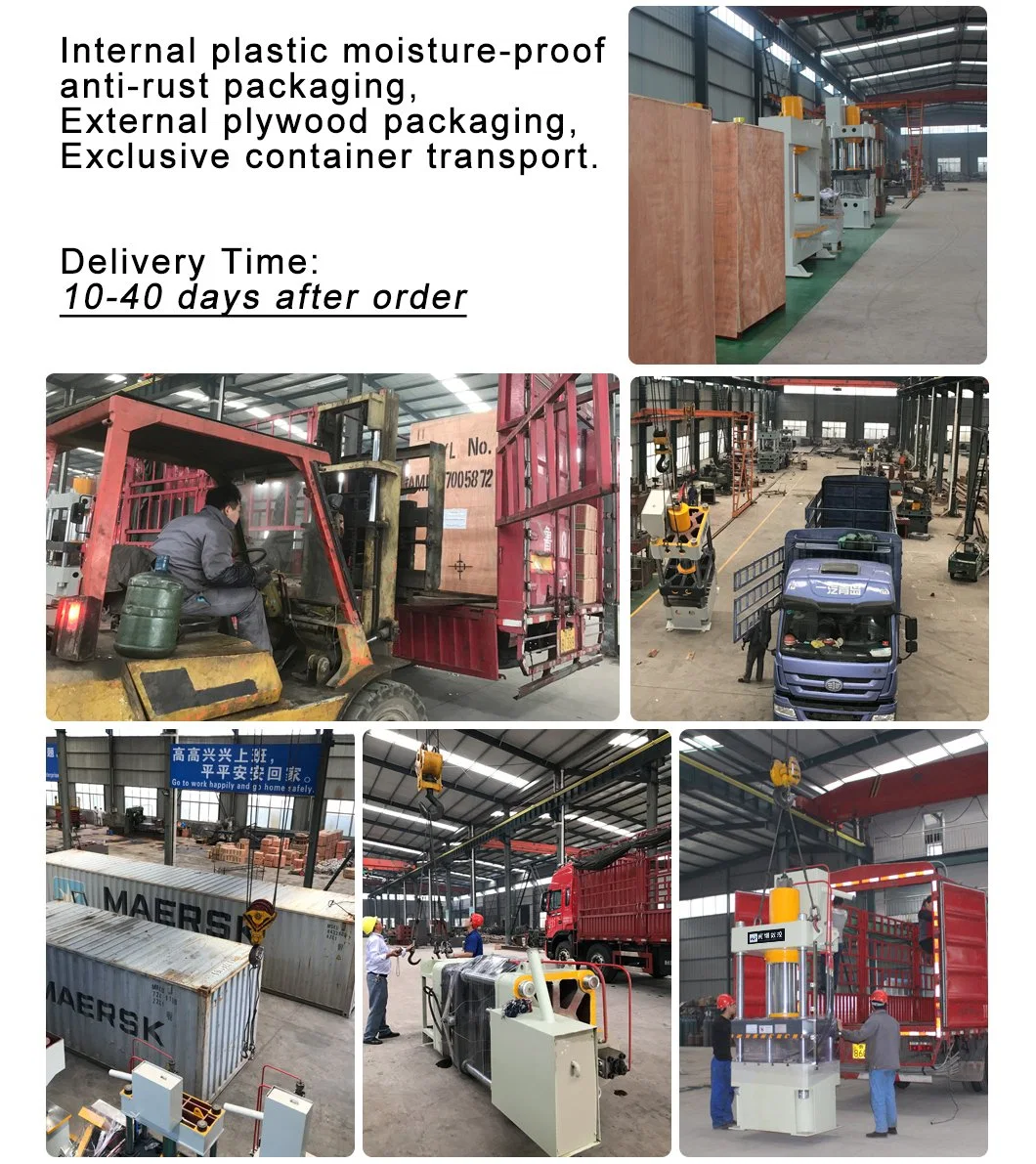

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

| SPECIFICATION | UNIT | YQ32-63T | YQ32-100TA | YQ32-100TB | YQ32-200TA | YQ32-200TB | YQ32-315TA | YQ32-315TB |

| Nominal force | KN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Max.System pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.Open height | mm | 700 | 800 | 900 | 1200 | 900 | 1250 | 1000 |

| Max.Stroke of slider | mm | 400 | 500 | 600 | 700 | 600 | 800 | 600 |

| Effective table size | mm | 610x500 | 630x550 | 750x700 | 1000x1000 | 800x800 | 1260x1160 | 800x800 |

| Down speed | mm/s | 180 | 120 | 120 | 100 | 100 | 100 | 100 |

| Pressing speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-11.5 | 7-11.5 |

| Return speed | mm/s | 100 | 120 | 120 | 70 | 70 | 60 | 60 |

| Ejection cylinder force | KN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Stroke of ejectioncylinder | mm | 160 | 200 | 200 | 220 | 220 | 300 | 300 |

| SPECIFICATION | UNIT | YQ32-400T | YQ32-500T | YQ32-630T | YQ32-800T | YQ32-1000T | YQ32-1250T | YQ32-1600T |

| Nominal force | KN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Max.System pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Max.Open heigh | mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Max.Stroke of slider | mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Effective table size | mm | 1260x1160 | 1400x1400 | 1600x1600 | 1500x1500 | 1500x1500 | 1800x1600 | 1600x1600 |

| Down speed | mm/s | 100 | 100 | 80 | 80 | 80 | 80 | 80 |

| Pressings pee | mm/s | 5-9 | 8-15 | 6-12 | 8-17 | 6-13 | 7-15 | 8-17 |

| Return speed | mm/s | 55 | 70 | 60 | 70 | 70 | 70 | 70 |

| Ejection cylinder force | KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Stroke of ejectioncylinder | mm | 300 | 300 | 300 | 350 | 350 | 350 | 350 |

Both the slide and the worktable of the machine are engraved with T-slots, facilitating the quick installation and replacement of molds.

Both the slide and the worktable of the machine are engraved with T-slots, facilitating the quick installation and replacement of molds. This machine is equipped with an independent pump station and a mobile control cabinet, facilitating machine maintenance and enabling employees to operate the machine easily.

This machine is equipped with an independent pump station and a mobile control cabinet, facilitating machine maintenance and enabling employees to operate the machine easily. This machine is equipped with a stroke control switch, which can control the stroke of the slide and the die, ensuring accurate positioning and pressure during operation, thereby improving production efficiency and product quality from the perspective of the mechanical industry.

This machine is equipped with a stroke control switch, which can control the stroke of the slide and the die, ensuring accurate positioning and pressure during operation, thereby improving production efficiency and product quality from the perspective of the mechanical industry. From the perspective of the mechanical industry, the interior of the electrical cabinet of this machine is neatly arranged, facilitating maintenance in the later stage.

From the perspective of the mechanical industry, the interior of the electrical cabinet of this machine is neatly arranged, facilitating maintenance in the later stage. From the perspective of the mechanical industry, this machine adopts integrated cartridge valves to reduce leakage points and prevent hydraulic oil from leaking under high pressure.

From the perspective of the mechanical industry, this machine adopts integrated cartridge valves to reduce leakage points and prevent hydraulic oil from leaking under high pressure. From a mechanical industry perspective, this machine is equipped with a 7.5kW standard motor, providing powerful driving force, and can also be optionally configured with a more energy-efficient servo motor.

From a mechanical industry perspective, this machine is equipped with a 7.5kW standard motor, providing powerful driving force, and can also be optionally configured with a more energy-efficient servo motor. From a mechanical industry perspective, the electrical cabinet is equipped with a hydraulic pressure gauge and pressure adjustment knob, facilitating pressure monitoring and adjustment.

From a mechanical industry perspective, the electrical cabinet is equipped with a hydraulic pressure gauge and pressure adjustment knob, facilitating pressure monitoring and adjustment. The products shown in the above figure are part of the products produced by some customers using our machines. If you are unsure which machine to use, you can also consult us, and we will provide the best solution.

The products shown in the above figure are part of the products produced by some customers using our machines. If you are unsure which machine to use, you can also consult us, and we will provide the best solution.

Founded in 2006, Nadun Machinery Manufacture Co., Ltd. has emerged as a prominent manufacturer and exporter in the metal processing industry, boasting over 17 years of expertise. Focused on hydraulic presses, punch presses, shearing machines, bending machines, and vertical lathes, we cater to a wide array of sectors such as automotive manufacturing, aerospace, construction, mechanical engineering, and metallurgy. With our products distributed across 150+ countries and regions globally, we persistently pioneer innovations and establish fresh benchmarks in the realm of machinery manufacturing.

Address:NO.219,Xingye road ,Tengzhou, Zao zhuang, Shangdong province, China

1. May I obtain the required documentation?

Certainly, we provide various documents including Certificates of Analysis/Conformance, insurance particulars, origin certificates, and other essential export paperwork.

2. What's the usual lead time?

For samples, it's approximately 30 days, and for mass production, it typically ranges between 30 to 60 days from when the deposit is received. Our lead times start upon deposit receipt and final product approval. If our lead times don't match your schedule, please consult your assigned sales representative. We strive to accommodate your requirements whenever feasible.

3. What payment methods do you accept?

We receive payments through bank transfer, Western Union, or PayPal. Our standard terms involve a 30% upfront deposit, with the remaining 70% balance payable upon presentation of the B/L copy.

4. What are the terms of product warranty?

Our commitment encompasses both materials and workmanship. Even beyond the warranty period, we endeavor to address and resolve all customer concerns to ensure complete satisfaction.

5. Can you guarantee the safe delivery of products?

Certainly, we utilize high-quality export packaging for secure delivery. Specialized packing is utilized for hazardous goods, and validated cold storage shippers are employed for temperature-sensitive items. However, specific packaging requirements may result in additional charges.

6. How are shipping costs determined?

Shipping expenses are contingent upon the selected delivery method. Express delivery is quicker but more costly, while sea freight is preferable for larger quantities. Detailed freight rates can be provided once we have specific order details such as quantity, weight, and preferred shipping method. Please don't hesitate to reach out to us for further clarification.