- Overview

- Product Description

- Detailed Photos

- Product Parameters

Basic Info.

Packaging & Delivery

Product Description

Precision equipment manufacturing requires the accuracy and consistency provided by a 120 Ton H Frame Hydraulic Press Machine. This equipment shapes and corrects workpieces by applying pressure, excelling in component assembly for precision and reproducibility. It also calibrates sheet metal profiles, enhancing overall precision. With the ability to preset pressure and perform production tasks, this machine is a crucial multiplier in the precision equipment fabrication workflow.

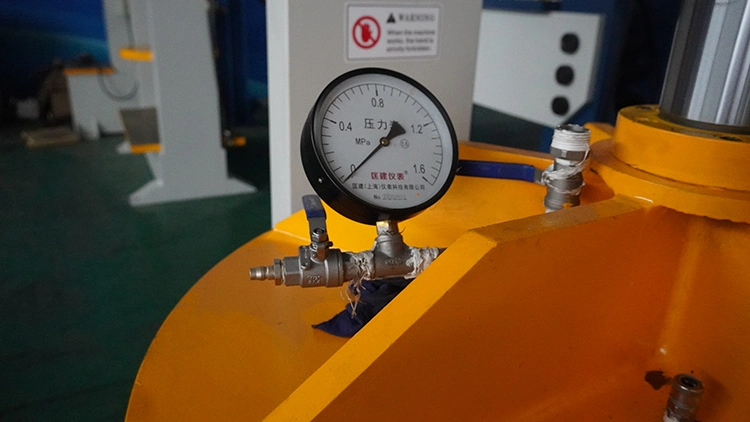

The main goal of pressure testing the piston head in a container ship's diesel engine is to confirm its integrity and detect potential damage or cracks.

The procedural steps:

1) Inject water into the piston head for complete filling, using a circular rubber pad as a sealing pad beneath the pressure-receiving surface.

2) Employ a hydraulic press to firmly unite the pressure plate and piston head, creating a sealed space.

3) Connect a hand pump to the valve on the pressure plate to pressurize and ventilate the sealed space. Close the pressure valve upon reaching the predetermined pressure level.

4) Maintain internal pressure for a specified duration. Examine pressure gauge changes and potential leakage points around the piston head to determine damage presence.

| MODEL | UNIT | YM-20 | YM-40 | YM-63 | YM-100 |

| Nominal force | KN | 200 | 400 | 630 | 1000 |

| Max system pressure | Mpa | 31.5 | 31.5 | 31.5 | 31.5 |

| Open height | mm | 560 | 560 | 560 | 600 |

| Stroke | mm | 200 | 200 | 220 | 220 |

| Table effective area | mm | 450x400 | 500x400 | 500x400 | 600x550 |

| Blanking hole diameter | mm | Ф60 | Ф80 | Ф100 | Ф140 |