Basic Info.

Model NO.

M400

Automation

Automatic

Certification

CE

Old and New

New

Electrical Machinery

44kw

Shear Force

400t

Blade Length

1500mm

Cutting Specifications

80*80

Shear Frequency

5-8 Times

Transport Package

Wooden Box

Specification

80*80/φ 80

Trademark

Fude

Origin

Henan China

HS Code

8462390000

Production Capacity

8t

Packaging & Delivery

Package Size

520.00cm * 160.00cm * 220.00cm

Package Gross Weight

25000.000kg

Product Description

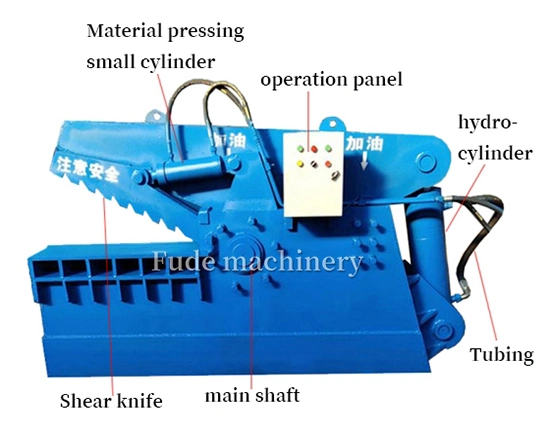

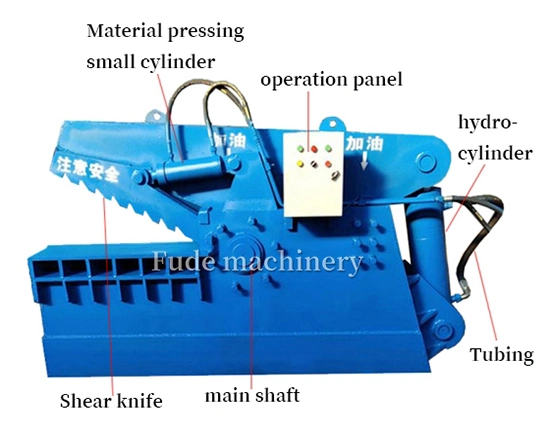

------ Introduction to Crocodile Shearing Machine ------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

The crocodile type shearing machine is suitable for metal recycling companies, scrap steel factories, and smelting and casting enterprises to perform cold cutting on various shapes of steel profiles and metal structures to process qualified furnace materials. The crocodile shearing machine can be continuously operated automatically or manually in a single operation, making it a good processing equipment for cutting heavy waste, light and thin furnace materials, and steel bars.

------ Performance characteristics ------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

1. Adopting hydraulic drive, easy to operate and easy to maintain.

2. Working blade length: 800mm, 1000mm, 1200mm, with shear force ranging from 160 tons to 250 tons in three levels. A cutting machine with a cutting edge of over 1000mm is suitable for cutting scrapped cars.

3. Installation does not require foundation screws, and diesel engines can be used as power in areas without power supply.

2. Working blade length: 800mm, 1000mm, 1200mm, with shear force ranging from 160 tons to 250 tons in three levels. A cutting machine with a cutting edge of over 1000mm is suitable for cutting scrapped cars.

3. Installation does not require foundation screws, and diesel engines can be used as power in areas without power supply.

4. The equipment adopts hydraulic transmission, which has advantages such as small volume, light weight, low inertia, low noise, stable operation, convenient operation, large cutting section, and convenient adjustment of the scissors compared to mechanical transmission shear machines. It is easy to operate and use, and easy to achieve overload protection.

------ Four major advantages ------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

1. Imported configuration: Imported configuration, making machine performance more stable and reliable to use

2. Factory direct sales: buy satisfactory products at ideal prices

3. After sales service: Receive customer service 24 hours a day to provide the fastest way to solve problems

4. Professional training: Professional technical personnel are responsible for training and guidance

2. Factory direct sales: buy satisfactory products at ideal prices

3. After sales service: Receive customer service 24 hours a day to provide the fastest way to solve problems

4. Professional training: Professional technical personnel are responsible for training and guidance

------ Working principle ------

-------------------------------------------------------------------------------------------------------------------  ------ Applicable material diversification ------

------ Applicable material diversification ------

-------------------------------------------------------------------------------------------------------------------

------ Cutting effect ------

------ Cutting effect ------

-------------------------------------------------------------------------------------------------------------------

------ Product display ------

------ Product display ------

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

The crocodile shear is composed of a shearing cylinder, a shearing knife, a slider pressing knife, a lower knife seat, a pressing oil cylinder, etc. When the shearing work is running, the hydraulic pump station (power output source) supplies oil to the pressing oil cylinder to push the slider pressing knife onto the lower knife seat, completing the fixed compression of the material. Then, the hydraulic pump station supplies oil to the shearing oil cylinder to push the shearing knife downward to complete the shearing step. After the shear is completed, the hydraulic pump station completes the return movement under the hydraulic oil reflux drive of the shear cylinder and the compression cylinder.

-------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------

------ Product display ------

------ Product display -------------------------------------------------------------------------------------------------------------------------

| Zhengzhou Fude Machinery Equipment Co, Ltd,Established in 2015,A factorythat integrates machine research, development, manufacturing, and sales,Main production: metal briquetting machines, wood crushers, and large andmedium-sized equipment for dryers. Service tenet:Integrity based management, To ensure quality control,Satisfy both parties. |

FAQ

Q:Are you a trading company or a manufacturing factory?

A:We are a factory.

Q:What is your delivery time?

A:If the goods are in stock, it usually takes 7-10 days.

If the goods are out of stock, it will take 15 to 30 days, calculated by quantity.

Q:What is your payment method?

A:30% of the total price should be paid in T/T as the down payment; 70% of the remaining payment should be paid in T/T before delivery.

Q:Do you provide technical guidance?

A:Yes, we will provide you with professional advice on the selection of models and the operation of equipment.

Q:Are you a trading company or a manufacturing factory?

A:We are a factory.

Q:What is your delivery time?

A:If the goods are in stock, it usually takes 7-10 days.

If the goods are out of stock, it will take 15 to 30 days, calculated by quantity.

Q:What is your payment method?

A:30% of the total price should be paid in T/T as the down payment; 70% of the remaining payment should be paid in T/T before delivery.

Q:Do you provide technical guidance?

A:Yes, we will provide you with professional advice on the selection of models and the operation of equipment.