- Overview

- Detailed Photos

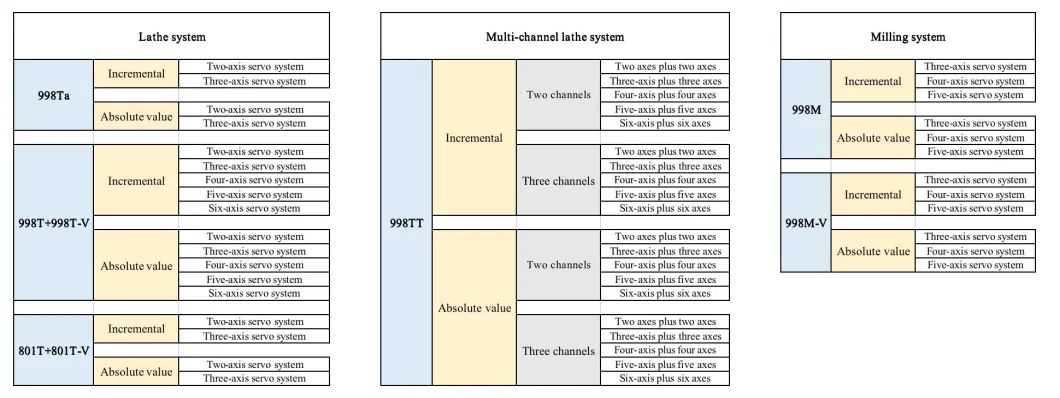

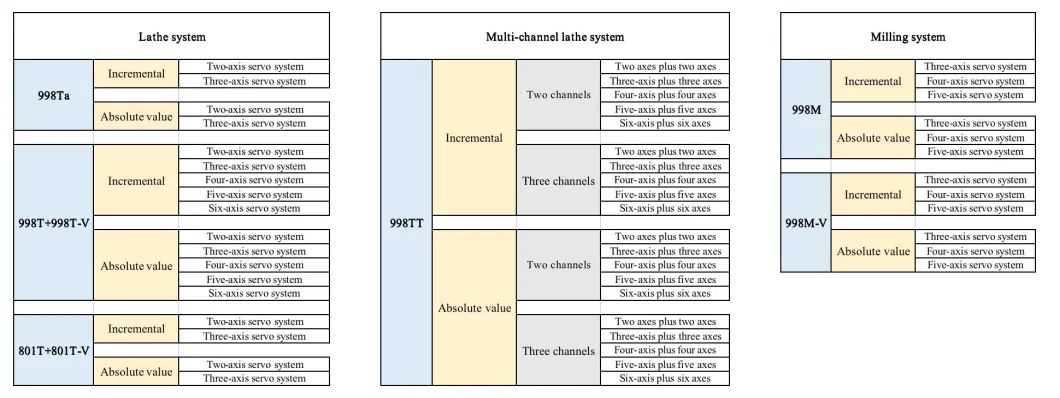

- CNC system overall solution

- Product Parameters

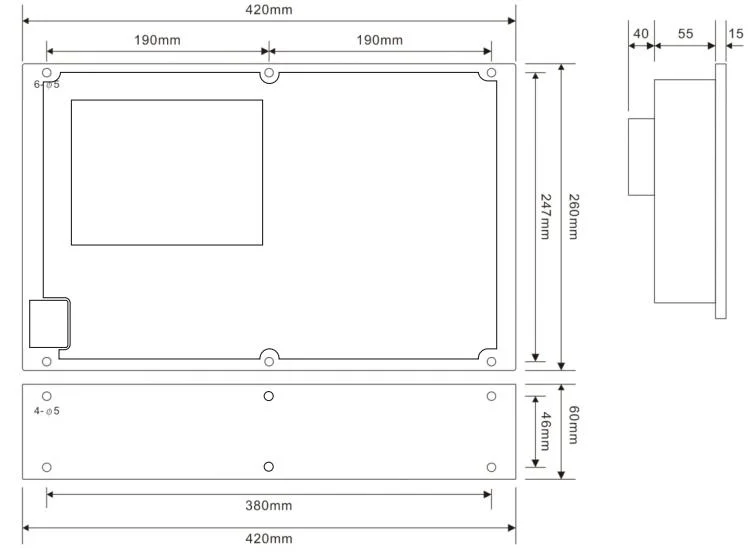

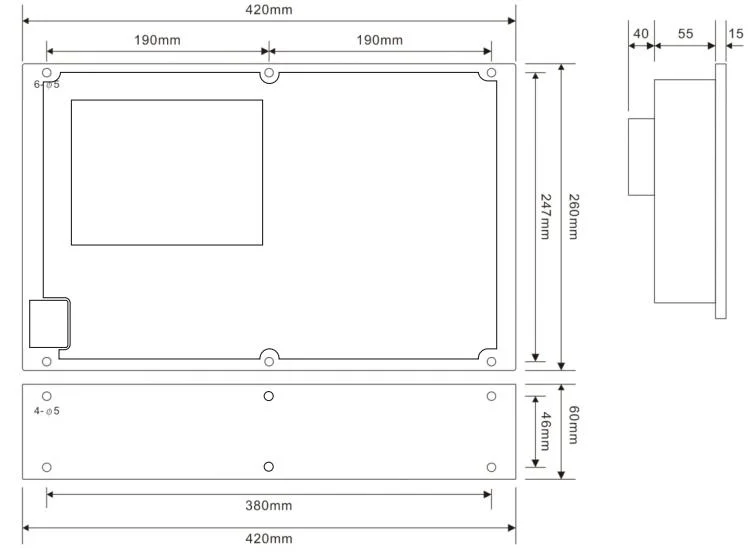

- Product Size

- CNC system collection

- Company Profile

Basic Info.

Model NO.

801T

Process Usage

Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools

Movement Method

Linear Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

Mid-Range CNC Machine Tools

Certification

CE

Condition

New

Screen Size

8 Inch

CPU

Arm(32bit)+Cpld

RAM

256MB

User Store ROM

800kb

Color

Black

Transport Package

Carton

Specification

420*260*118

Trademark

QB

Origin

Chongqing China

Production Capacity

500

Packaging & Delivery

Package Size

60.00cm * 40.00cm * 40.00cm

Package Gross Weight

8.000kg

Product Description

801T adopts a new appearance mold, a 32-bit high-performance CPU and a very large-scale programmable gate array integrated circuit chip CPLD form the control core to achieve μ m-level precision motion control. Full-screen editing program, Chinese operation interface, with Chinese input method, real-time tracking and display of processed parts graphics, simple and intuitive operation, and fast response speed, which has a high performance-price ratio.

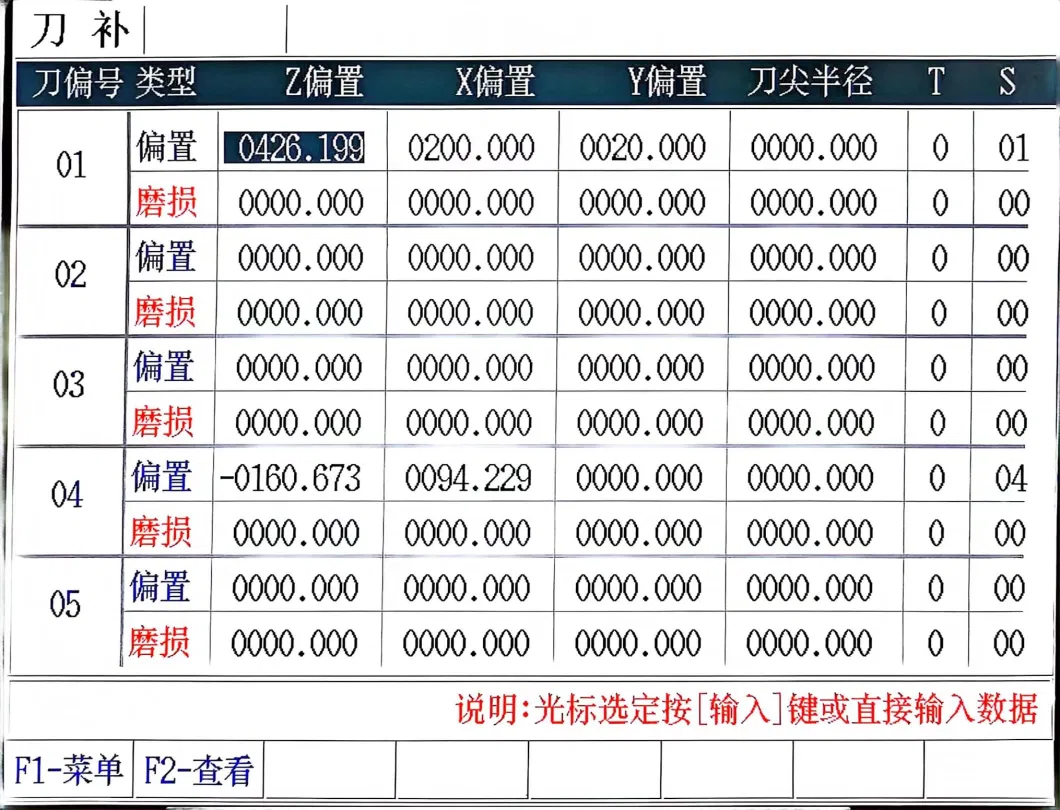

Simple user storage program interface

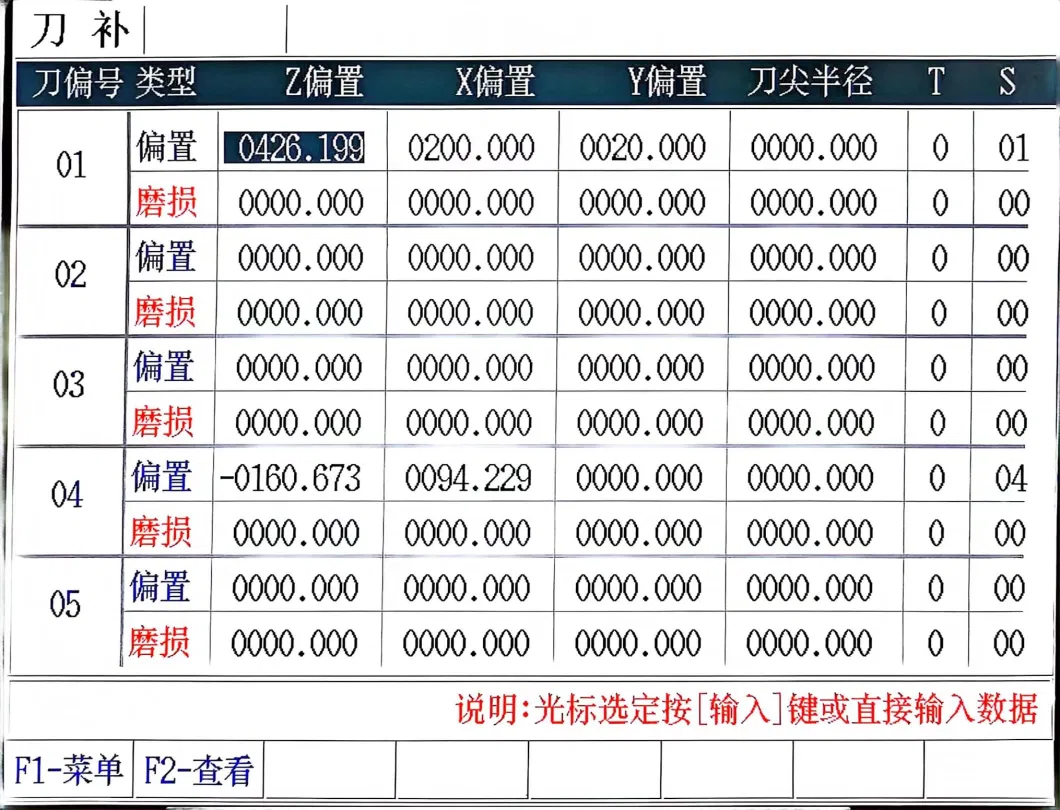

Intuitive tool interface

System Rear Cover Diagram

We can provide you with overall CNC system solutions

1) CNC system 2) Servo drive 3) Servo motors 4) Spindle drive 5) Spindle motor 6) Transformer 7) Encoder 8) Pulses

| Lathe CNC controller |

| 1. Standard Modbus485 bus protocol |

| 2. Pulse increment and absolute value functions |

| 3. Single channel, two channel and three channel system, maximum 6 axes + 6 plus + 6 axes |

| AC servo motor |

| 1. 2500-line incremental encoder motor |

| 2. 17-bit absolute encoder motor |

| Server Driver |

| 1. Pulse incremental driver |

| 2. Pulse absolute value driver |

| AC servo spindle motor and driver |

| 1. Pulse and +10V analog voltage control |

| External hand pulse |

| Spindle encoder |

| 380V isolation transformer |

| ♦X, Z, Y three-axis linkage, can realize short linear high-speed smooth interpolation, 0.001mm interpolation accuracy, the maximum fast speed of 30 m/min. |

| ♦The Y-axis (set by parameters) is optional. The Y-axis can not only realize rapid movement, feed (jog/single step/manual pulse feed) movement, and independent tapping movement, but also can set the coordinate system and program zerio return, manual machine tool zero return and other operations |

| ♦Controllable servo spindle |

| ♦Programming is flexible and convenient, with statement programming function |

| ♦Support Chinese programming operation |

| ♦USB interface communication, easy to operate, fast |

| ♦Minimum command unit 0.001mm, command electronic gear ratio (1~99999 )/(1~99999) |

| ♦Can realize a variety of automatic knife holder, spindle automatic shift control |

| ♦With pitch error compensation, reverse clearance compensation, tool length compensation, tool radius C compensation function |

| ♦Adopts exponential acceleration and deceleration control to adapt to high speed and high precision machining. |

| ♦With automatic chamfering function |

| ♦With tapping function |

| ♦With process monitoring function |

| ♦Can cut metric and inch threads, end face thread, variable pitch thread, continuous thread; thread high-speed back-end processing |

| ♦Parts program full-screen editing, can store 255 processing programs; Among them, the 253 program can reach a maximum capacity of 4MB |

| ♦Large screen true color LCD display, color configuration can be selected by the parameters |

| ♦Real-time tracking display of MSTF state during machining |

| ♦Provides multi-level operation password function, convenient equipment management |

| ♦Parameter backup function |

| ♦Parameters, tool compensation data communication function |

| ♦Supports two-way communication between CNC and CNC and PC, and CNC software can be upgraded with serial port |

| ♦Supports CNC and USB two-way communication, CNC software can USB upgrade |

| ♦Support bus 485 absolute value communication |