Basic Info.

Model NO.

8 *5000mm

Warranty

2 Years

Transport Package

Standrad

Specification

5400*2400*2000mm

Trademark

ysdcnc

Origin

Nanjing

HS Code

8462312000

Production Capacity

600 Sets/Year

Product Description

automatic shearing machine manufacturers 8 *5000mm /5m hydraulic guillotine shearing machine

hydraulic shearing machine

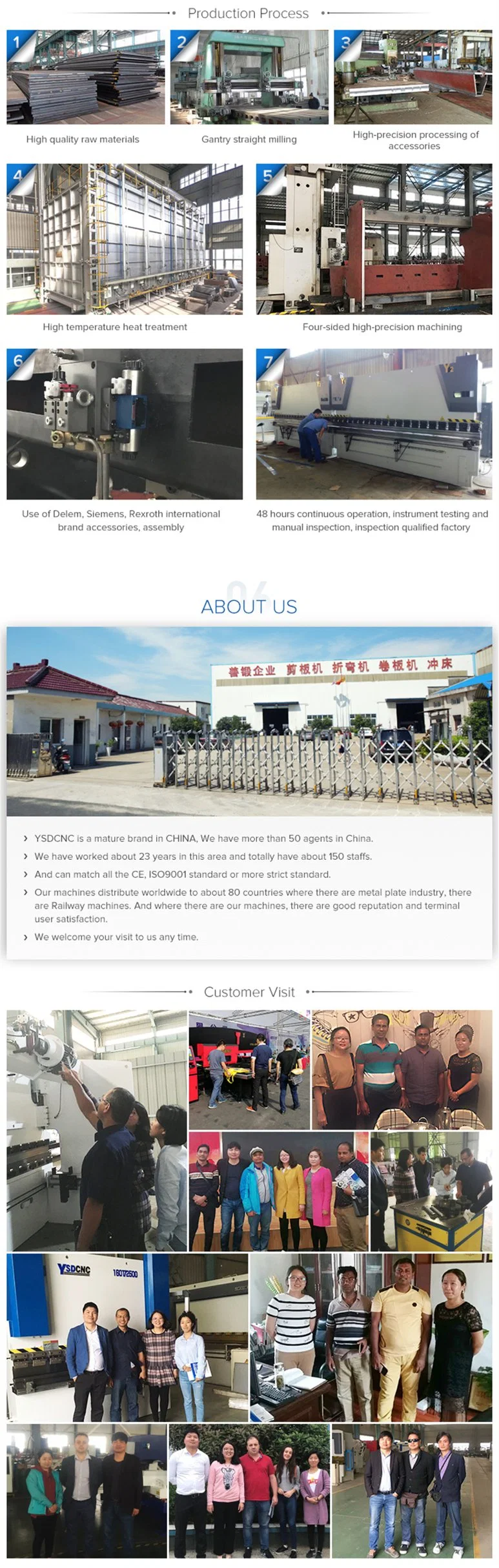

Nanjing Shanduan CNC Machine Tool Co., Ltd is one of the Top 3 press brake and shearing machine in China, which specializing in manufacturing and marketing of press brake,shearing machine,press machine, square duct production line LINE5,4,3,2,1;spiral duct machine, locking forming machine;folding machine,plasma cutting machine, power press,ironworker,hydraulic notching machine, beading machine,flange forming machine,shearing machine & press brake,Blade/Mold, etc.

| Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

| Brand: YSDCNC |

| Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

| Tel:+86 025-57262305 Phone:+86 18851629789 |

1. Main Features:

- Streamlined design originated from EU, main structure consists of rack, cutter holder, oil cylinder, hydraulic controller, backgauge and others. Finite-element analysis of main parts, Welding parts uses tempering, vibration and other processing methods to eliminate stress ensuring the structural strength and rigidity of each component;

- Cutter holder use three-point support rolling guide rail, reducing the friction to the greatest extent, and realizing seamless rolling during cutter holder moving.

- Left-most front holder configured with verticality regulator and front positioning device, easy operation and high efficiency;

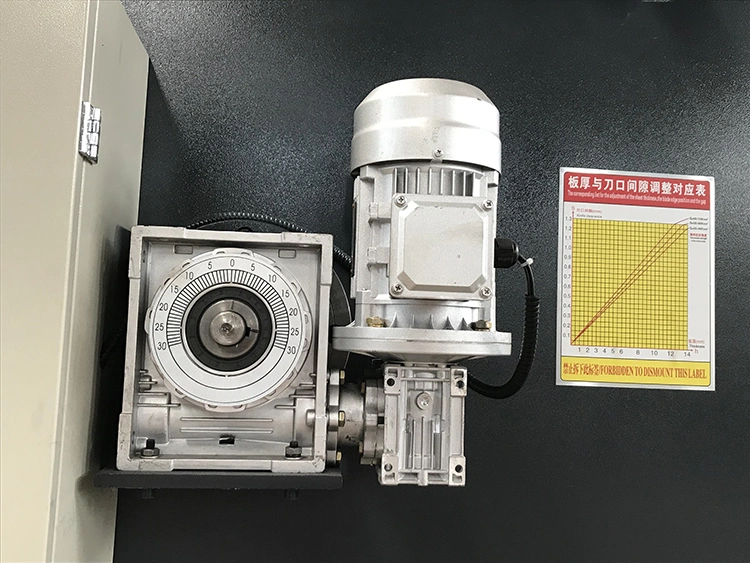

- Simple and effective blade adjusting mechanism rearranges blade clearance by CNC system, improving the cutting quality.

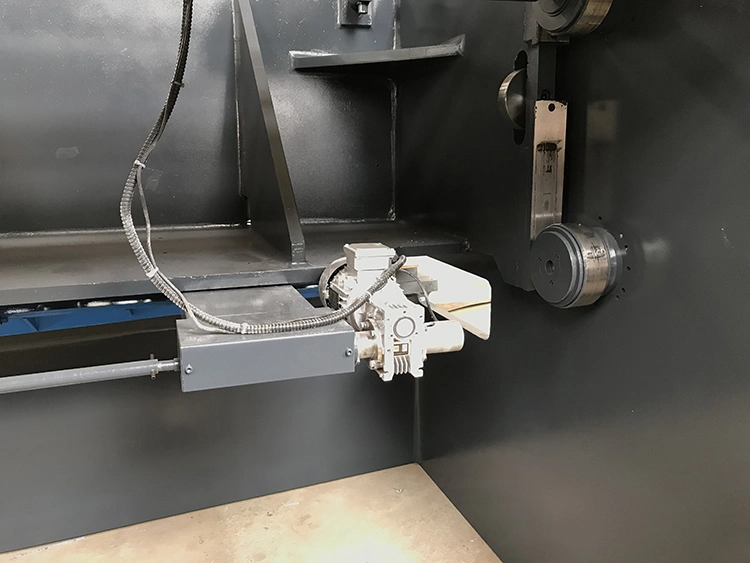

- Fine ball screw and polished rod structure, using good-performance frequency converter positions X axis to ensure accuracy, unique designed timing transmission mechanism, stable and reliable.

- Light and shadow line is conductive to manual scribing for cutting; stable and reliable hydraulic transmission; integrated hydraulic system is able to significantly alleviate problems causing by hydraulic fluid leakage.

- Made by high-quality alloy tool steel capable enough to against impact load and high wear resistance when cutting;

- With reference to ergonomic design, easy operation with CNC system surface, improving the operation precision and comfortability; rolling ball workbench to reduce friction and prevent work piece surface from scratching; unique and practical safety guard, line with safety specifications, protect the personal safety; exquisite design, petty work piece can be done easily by hand.

- Estun E21S CNC controller

- Electrically controls backgauge X-axis

- DELTA frequency converter and controller

- HIWIN ball screw and polished rod, control accuracy of 0.05mm.

- Controller cantilever and front supporter

- Germany EMB oil tube connector and high-pressure hose

- Germany Siemens main motor

- Hydraulic and electrical overload protection

- Light aligning

- Blade materials ( 6CrW2Si )

- South Korea KACON pedal switch

- Cutting angle adjustment

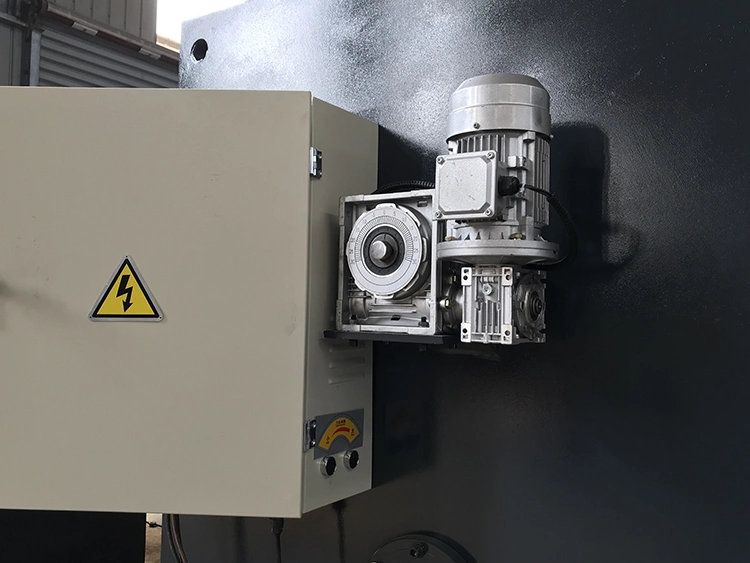

- Electrically adjusts the blade clearance

- Safetry standards(2006/42/EC)

- Open electric cabinet and front safeguard door to cut off power

- South Korea KACON pedal switch ( safety grade 4 )

- Rear metal safeguard rail, CE standard

- Safety relay monitors pedal switch, safety protection

- High-definition LCD display with bilingualism of Chinese and English, multi-step programming,40 programs,25 working steps each program

- Backgauge: intelligent positioning or manually adjusts when need, removing mechanical hand positioning device.

- Cutting stroke: built-in time relay, easy operation and low cost

- Cutting angle: built-in adjusting device for regulating cutting angle, removing angle indicator and button

- Blade clearance: encoder feedback, timely display the clearance between blades

- One-key restores and backup parameters

- Control the cutting angle and blade clearance

- mm /inch

| Type Item | Unit | 4*2500 | 4*3200 | 4*4000 | 6*2500 | 6*3200 | 6*4000 | 8*2500 | 8*3200 | |

| Cutting Thickness | mm | 4 | 4 | 4 | 6 | 6 | 6 | 8 | 8 | |

| Cutting Length | mm | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 2500 | 3200 | |

| Cutting Angel | ° | 1°30′ | 1°30′ | 1°30′ | 1°30′ | 1°30′ | 1°30′ | 1°30′ | 1°30′ | |

| Meterial Strength | KN/CM | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

| Stopper Adjust Range | mm | 20-500 | 20-500 | 20-600 | 20-500 | 20-500 | 20-600 | 20-500 | 20-500 | |

| Travel Times | times/min | 16 | 13 | 10 | 15 | 12 | 9 | 11 | 8 | |

| Power | KW | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

| Dimensions | L | mm | 3040 | 3840 | 4600 | 3040 | 3840 | 4600 | 3040 | 3860 |

| W | mm | 1550 | 1550 | 1700 | 1710 | 1710 | 1850 | 1710 | 1710 | |

| H | mm | 1550 | 1550 | 1700 | 1620 | 1620 | 1700 | 1710 | 1710 | |

| Weight | KG | 3000 | 4200 | 6000 | 4500 | 5600 | 6600 | 5200 | 6200 | |

Major Import configuration list:

| NO | UNIT | NUMBER | MARK |

| 1 | CONTROL SYSTEM | 1set | E21S (ESTUN) |

| 2 | HYDRAULIC SYSTEM | 1set | REXROTH VALVE |

| 3 | Ball screw | 2sets | Taiwan HIWIN |

| 4 | Sealing ring | 1set | FIETZ, Japan, VALQUA, Japan. |

| 5 | Major electrical components | 1set | SCHNEIDE |

| 6 | Motor | 1 set | SIEMENS |

| 7 | CUTTING BLADE | 1 set | YSDCNC |

Random tools/documents:

| Serial No. | Name | Quantity | Remark |

| 1 | Main unit | 1 | Including one set of upper and lower die, front plate holder and foot switch |

| 2 | Grease gun | 1 | |

| 3 | Button key | 2 | |

| 4 | Key to door lock | 2 | |

| 5 | Product instructions | 1 | |

| 6 | certificate of quality | 1 | |

| 7 | Packing list | 1 | |

| 8 | Foundation bolt | 4 sets | Including nuts and washers |

| 9 | O-type sealing ring | 16 |

hydraulic shearing machine