Basic Info.

Model NO.

QC11K

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Linear Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001

Condition

New

Controller

P40t

Transport Package

Standard Safe Package

Specification

3040*1550*1550mm

Trademark

HARSLE

Origin

Jiangsu, China

HS Code

8462319000

Production Capacity

5000 Sets a Year

Packaging & Delivery

Package Size

50.00cm * 40.00cm * 30.00cm

Package Gross Weight

500.000kg

Product Description

| FEATURES |

1. The mainframe is fitted with numeric-control system special for shearing machines.

2. The position of rear stopper is displayed in a real-time manner.

3. Multistage programming function is available and the rear stopper is able for automatic operation and continuous positioning, to achieve an automatic adjustment for position of rear stopper.

4. It is provided with counting function for shearing, to display the shearing numbers in a real-time manner, able for power-failure memory of position of rear stopper, procedures and parameters.

5. Imported ball bearing lead screw and liner guide rail are used to ensure the positioning precision, so that the processing precision of machine is higher.

A guillotine shearing machine, often simply referred to as a guillotine shear or power shear, is a machine tool used in metalworking and fabrication to cut sheet metal with a straight, vertical cutting action. The design of the machine is reminiscent of the guillotine, a device used for executions, hence the name.

Here are the key components and features of a guillotine shearing machine:

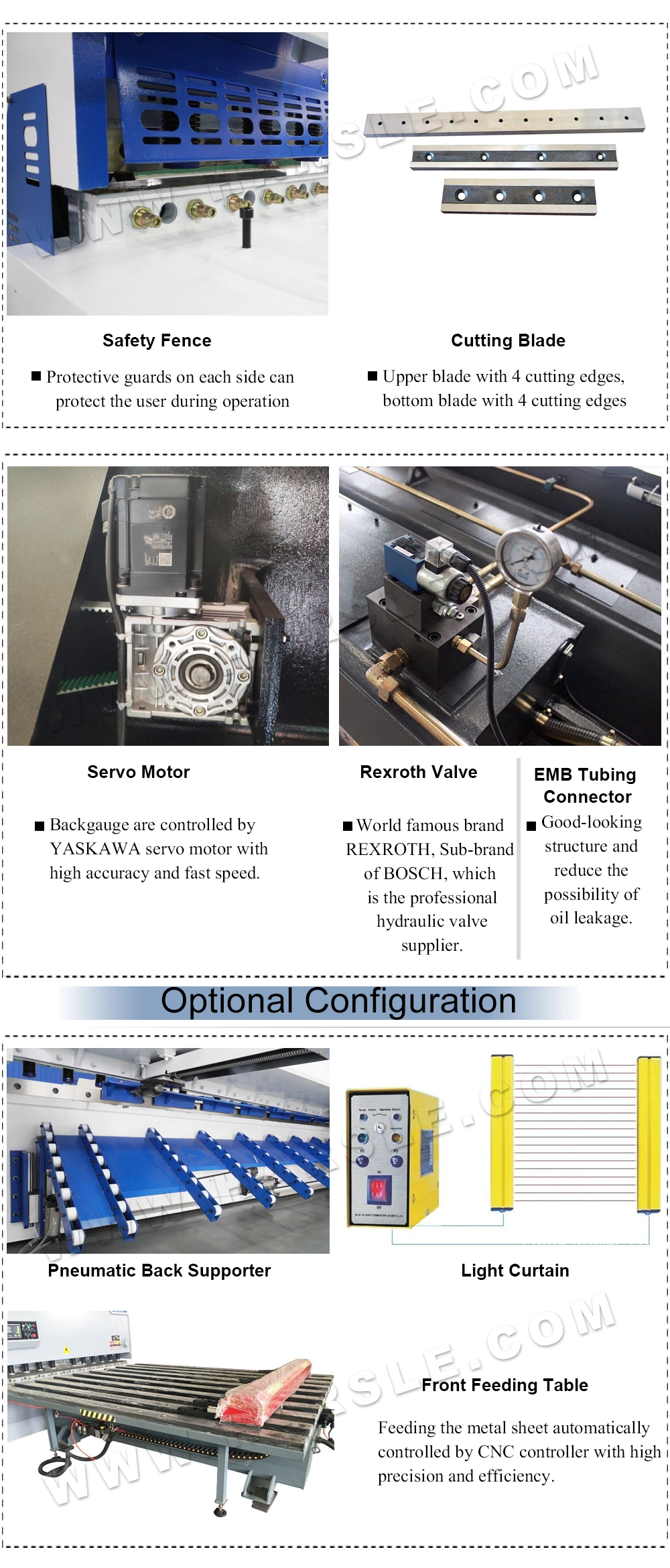

Blade Assembly: The blade assembly is the cutting tool of the shearing machine. It typically consists of a fixed upper blade and a movable lower blade. The blades have a sharp edge and move against each other to cut through the sheet metal.

Back Gauge: The back gauge is an adjustable stop that allows the operator to position the sheet metal accurately before making a cut. This feature ensures precision in the cutting process.

Hold-Downs: Hold-downs are clamping devices that secure the sheet metal in place during the cutting operation. They prevent the material from lifting or shifting during the cut, ensuring clean and accurate cuts.

Hydraulic System: Many modern guillotine shearing machines use hydraulic systems to power the cutting action. The hydraulic system provides the force needed to move the blades and make the cut.

Control Panel: The control panel allows the operator to set parameters such as cutting length, back gauge position, and cutting speed. It may have a digital display for accurate adjustments.

Foot Pedal or Control Lever: Operators can control the cutting action using a foot pedal or a control lever. This allows for hands-free operation, as the operator uses their foot to initiate the cutting process.

Guillotine shearing machines are commonly used in metal fabrication shops for cutting large sheets of metal into smaller, more manageable pieces. They are efficient, versatile, and capable of producing straight, clean cuts. The size and capacity of guillotine shears can vary, with some machines designed for light-duty applications and others for heavy-duty industrial use. The choice of a guillotine shear depends on the thickness and type of material to be cut, as well as the required cutting length.