Basic Info.

Model NO.

YHA4-10T

Application

Edge Trimming, Shaping, Forming, Cutting, Punching

Oil

Hydraulic Oil

Force Capacity

10t

Max Stroke

300mm

Daylight(Max Open Height)

400mm

Mold Service

Available

Voltage

3 Phase 220V/380V/Customized

Oil Seal

Nok, Japan

Main Electronic Component

Schneider, France

Light Curtain

Fotek, Japan

Magnetic Valve

Omax. Taiwan

Oil Pump

Kcl, Taiwan

Term

Manufacturer

Type

Four-Column Hydraulic Press

Certification

ISO9001, CE

Transport Package

Standard Export Package

Specification

900*850*2105mm

Trademark

Yihui

Origin

Guangdong, China (Mainland)

HS Code

846291900

Production Capacity

500 Sets Per Year

Product Description

Product Description

Mental trimming machinery four pillar 10 ton single hydraulic press

Mental trimming machinery four pillar 10 ton single hydraulic press

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

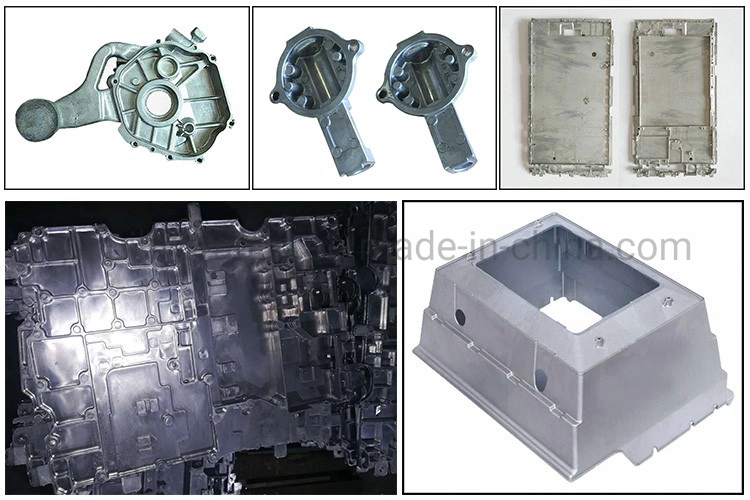

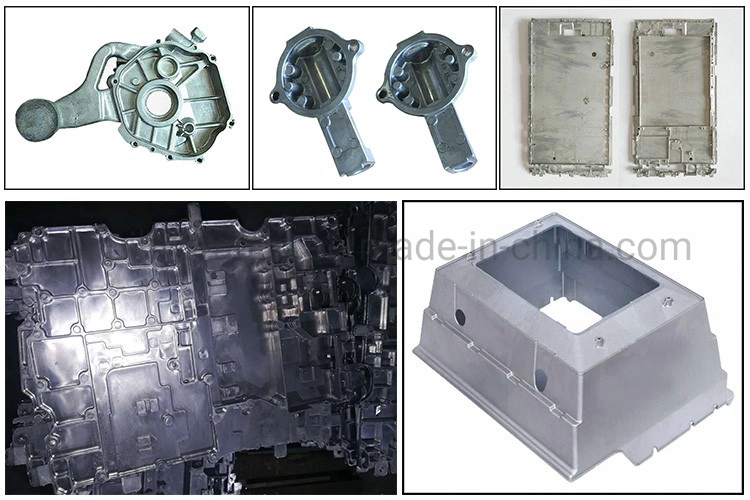

Product Application

1) Edge trimming and shaping for all kinds of aluminum alloy die castings and magnesium alloy die castings.

2) Most widely used in fields like aluminum magnesium alloy mobile phone products, automobile and motorcycle parts die casting.

3) Shaping and trimming for metal or nonmetal.

Packing & Delivery

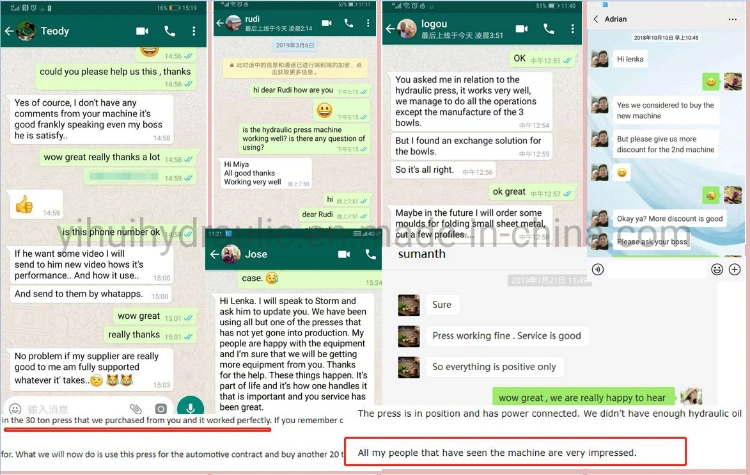

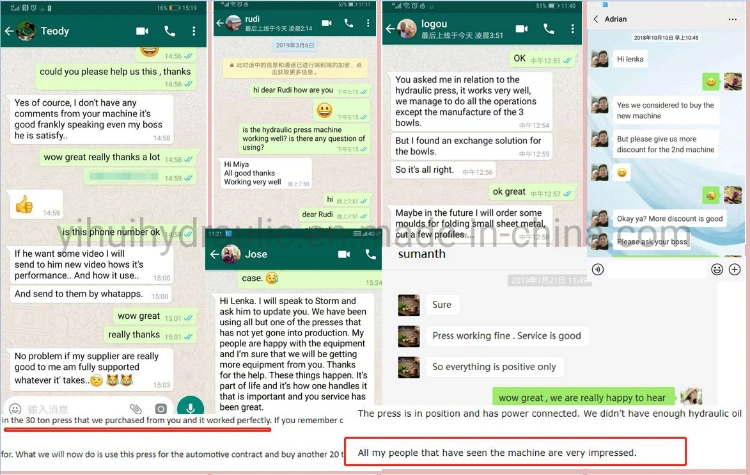

Our company Customer shows

Customer shows

Feedbacks from Customer

Exhibitions

Our advantages

1. Use servo control system with very good quality components.

2. Custom-made is available according to your detailed requirement.

3. We are able to provide whole production line, including molds, technical support and other equipments from other suppliers.

Certificate

FAQ

Q1: Are you trade company or manufacturer?

Answer: We are an enterprise with sales, R&D, manufacturing and patent.

Q2: Whether to provide quality assurance and complete after-sales support? Or say, does engineers available to

service overseas?

Answer: Yes!

Warranty period of Our hydraulic press machine is 12 months, if necessary,we support the site installation,

commissioning, technical guidance,and after-sales maintenance support.

Q3:How can I know what kinds of the machine and which size suits my needs best?

Answer: Before we have a deeper communication on the target machine, the drawings, material, pics, size and production

of the products you are willing to make are necessary.

Q4:Does customized is acceptable?

Answer: Yes, we accept customized when necessary.

Q5:Why choose us ?

Answer: 1.Our factory has specialized in independent development and producing hydraulic press for 20 years.

So the product is stable and with high quality.

2. About machine body, we use bending structure which is much stronger than the common welding structure .

3.About oil pipe, we use Clip-on structure which is tighter than common welding structure and can prevent oil from leakage.

4. We take integrated oil manifold block which is much easier to check and repair machine.

5.The main components are imported from Japan and Taiwan . So the quality of our machine is close to Japan

while the unit price is lower than Japan.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.

2) Most widely used in fields like aluminum magnesium alloy mobile phone products, automobile and motorcycle parts die casting.

3) Shaping and trimming for metal or nonmetal.

Technical Characteristics

1) Using built-in high speed cylinder, has fast falling speed and high production efficiency.

2) Four columns are made of high-strength alloy steel with hard chrome plated surface and good abrasion resistance.

3) Pressure, stroke and pressurizing time can be adjusted according to processing requirement.

4) Optional configuration: protective cover, anti-drop device, blowing chip removal device, LED lighting and infrared grating, etc.

Components Detail2) Four columns are made of high-strength alloy steel with hard chrome plated surface and good abrasion resistance.

3) Pressure, stroke and pressurizing time can be adjusted according to processing requirement.

4) Optional configuration: protective cover, anti-drop device, blowing chip removal device, LED lighting and infrared grating, etc.

| Item | Unit | Product Specifications | |||||

| YHA4-10T | YHA4-20T | YHA4-30T | YHA4-40T | YHA4-50T | |||

| Nominal Force | kN | 100 | 200 | 300 | 400 | 500 | |

| Max.Working Pressure | Mpa | 13 | 21 | 19 | 19 | 21 | |

| Master Cylinder Nominal Force | kN | 100 | 200 | 300 | 400 | 500 | |

| Max.Stroke of Ram | mm | 300 | 300 | 350 | 450 | 450 | |

| Daylight (Max.Open Height) | mm | 400 | 450 | 500 | 600 | 700 | |

| Middle Blanking Aperture Size | mm | 150*100 | 150*100 | 200*150 | 300*200 | 300*200 | |

| Speed of Ram | Down No Load | mm/s | 260 | 230 | 200 | 210 | 205 |

| Pressing | mm/s | 40 | 35 | 20 | 20 | 18 | |

| Return | mm/s | 260 | 225 | 200 | 200 | 200 | |

| Effective Area of Working Table | RL(Inside Column) | mm | 450 | 500 | 550 | 700 | 800 |

| FB(Edge) | mm | 450 | 500 | 550 | 600 | 650 | |

| Overall Dimension | L.R | mm | 900 | 900 | 980 | 1250 | 1340 |

| F.B | mm | 850 | 850 | 900 | 1100 | 1150 | |

| H | mm | 2105 | 2155 | 2270 | 2550 | 2750 | |

| The Distance Between the Working Table and the Ground | mm | 820 | 830 | 900 | 900 | 1000 | |

| Motor Power | kW | 3.75 | 3.75 | 3.75 | 5.5 | 5.5 | |

| Total Weight(Approx) | kg | 900 | 1020 | 1120 | 1650 | 2400 | |

| Oil Quantity(Approx) | L | 150 | 150 | 170 | 200 | 2 | |

Packing & Delivery

| Packing | |

| Size | Accordingly |

| Weight | Accordingly |

| Packaging Details | The normal package is wooden case(Size: L*W*H). The wooden case will be fumigated if needed. If container is too tight, we will use PE film for packing or pack it according to customers' special request. |

Our company

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

Dongguan Yihui Hydraulic Machinery Co., Ltd, is experienced in designing and manufacturing various types of hydraulic press

machines and stamping machines,especially specialized in manufacturing servo hydraulic press machine. The plant is established

in 1999 ,covers an area of 5,000 square meters.

We are strictly implement the ISO9001 , CE, and SGS management standards.

YIHUI brand presses have been exported to over 30 countries, such as Germany, USA, UK, Sweden, Japan, Slovenia,

Saudi Arabia, El Salvador, Togo, Malaysia, Singapore, Australia ,Vietnam, Pakistan, South Africa, and so on.Hydraulic

press machine mainly applied tohardware, automotive, die casting, electronic, cookware, paper and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

machines and stamping machines,especially specialized in manufacturing servo hydraulic press machine. The plant is established

in 1999 ,covers an area of 5,000 square meters.

We are strictly implement the ISO9001 , CE, and SGS management standards.

YIHUI brand presses have been exported to over 30 countries, such as Germany, USA, UK, Sweden, Japan, Slovenia,

Saudi Arabia, El Salvador, Togo, Malaysia, Singapore, Australia ,Vietnam, Pakistan, South Africa, and so on.Hydraulic

press machine mainly applied tohardware, automotive, die casting, electronic, cookware, paper and other industries.

We can provide total solutions, including machines, molds, product processing technology, automated production lines.

Feedbacks from Customer

Exhibitions

Our advantages

1. Use servo control system with very good quality components.

2. Custom-made is available according to your detailed requirement.

3. We are able to provide whole production line, including molds, technical support and other equipments from other suppliers.

Certificate

FAQ

Q1: Are you trade company or manufacturer?

Answer: We are an enterprise with sales, R&D, manufacturing and patent.

Q2: Whether to provide quality assurance and complete after-sales support? Or say, does engineers available to

service overseas?

Answer: Yes!

Warranty period of Our hydraulic press machine is 12 months, if necessary,we support the site installation,

commissioning, technical guidance,and after-sales maintenance support.

Q3:How can I know what kinds of the machine and which size suits my needs best?

Answer: Before we have a deeper communication on the target machine, the drawings, material, pics, size and production

of the products you are willing to make are necessary.

Q4:Does customized is acceptable?

Answer: Yes, we accept customized when necessary.

Q5:Why choose us ?

Answer: 1.Our factory has specialized in independent development and producing hydraulic press for 20 years.

So the product is stable and with high quality.

2. About machine body, we use bending structure which is much stronger than the common welding structure .

3.About oil pipe, we use Clip-on structure which is tighter than common welding structure and can prevent oil from leakage.

4. We take integrated oil manifold block which is much easier to check and repair machine.

5.The main components are imported from Japan and Taiwan . So the quality of our machine is close to Japan

while the unit price is lower than Japan.

6.Our factory can offer full set line service, such as the mould,process technology, and other relative machines.