Basic Info.

Structure Type

Desktop

Laser Classification

Solid Laser

Product Name

CNC Fiber Laser Metal Cutting Machine

Function

Cutting Metal Materials

Cutting Materials

Stainless Steel Carbon Steel

Laser Power

1500W/ 2000W / 3000W

Laser Head

Auto Focus Laser Head

Voltage

3 Phases 380V 50-60 Hz

Working Area

1500mmx3000mm / 2000mmx4000mm / 2000mmmx6000mm

Working Table

Sawteeth Working Table

Laser Source

Ipg Raycus Max

Positioning Accuracy

0.03mm

Repeatability Accuracy

0.03mm

Certification

CE/ISO Certificate

Transport Package

Fumigation-Free Plywood Wooden Box

Specification

1500mm*3000mm

Origin

China

Production Capacity

50 Sets/Month

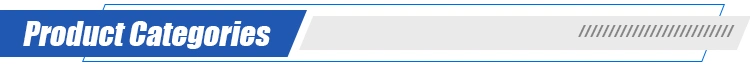

Product Description

Machine Features:

Machine Features: 1.High performance laser equipment, stable operating system, so that the cutting effect to achieve the best.

2. Perfect cooling, lubrication, dust removal system to ensure stable, efficient and durable machine operation.

3. Single table, equipped with auxiliary loading and unloading plate function, improve processing efficiency.

4. Large size closed box, improve the dust removal effect, avoid light pollution.

5. Automatic height adjustment performance, keep the focal length constant, excellent and stable cutting effect.

6. Gantry type structure, embedded cast aluminum beam, so that the equipment strong rigidity, good stability, good anti-knock performance.

Fiber Laser Cutting Machine Description:

1. Laser power: 1000W, 1500W, 2000W, 3000W, 4000W, 6000w, 10000w, 12000w, etc.

2. Laser generator: JPT, RAYCUS, MAX, RECI, IPG etc.

3. Single table, equipped with auxiliary loading and unloading plate function, improve processing efficiency.

4. Large size closed box, improve the dust removal effect, avoid light pollution.

5. Automatic height adjustment performance, keep the focal length constant, excellent and stable cutting effect.

6. Gantry type structure, embedded cast aluminum beam, so that the equipment strong rigidity, good stability, good anti-knock performance.

| Model | HXF-3015/4015/4020/6020 |

| Working Area | 3000*1500mm (customizable) |

| Laser Generator | Raycus/IPG/MAX |

| Laser Power | 1500w/2000w/3000w/4000W/6000W |

| Location Accuracy | 0.01mm |

| Repeat Location Accuracy | 0.01mm |

| Max Moving Speed | 140m/min |

| Materials Thickness | Max 40mm |

| Machine Warranty | 3 Years |

| Applicable Materials | Stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titaniu metc metal plate |

| Machine Color | Customizable |

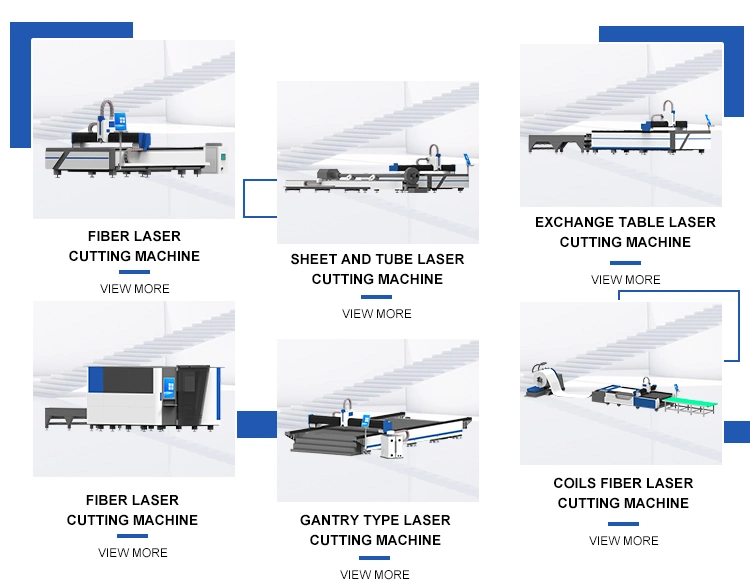

Fiber Laser Cutting Machine Description:

1. Laser power: 1000W, 1500W, 2000W, 3000W, 4000W, 6000w, 10000w, 12000w, etc.

2. Laser generator: JPT, RAYCUS, MAX, RECI, IPG etc.

3. Cutting materials: Iron, aluminum, carbon steel, stainless steel, copper, hardware and another metal sheet materials.

4. Other machine optional parts can be chosen, such as, rotary axis, exchange working table, full cover, etc.

5. China fiber laser machine cutting manufactuers, low cost and best quality, with CE, ISO etc certificates.

4. Other machine optional parts can be chosen, such as, rotary axis, exchange working table, full cover, etc.

5. China fiber laser machine cutting manufactuers, low cost and best quality, with CE, ISO etc certificates.

Auto-focus laser head

The laser head is made of high quality materials in accordance with advanced technology. Professional laser cutting head, stable and reliable technology, completely sealed inside the laser head, can avoid dust pollution to the optical part. The protective lens is installed in a drawer, which is convenient for replacement.

Laser cutting CNC system

The special CNC system of intelligent laser cutting machine is adopted to realize automatic edge searching, automatic typesetting, automatic focusing, automatic cutting, convenience and efficiency.A set of software specially customized for laser cutting industry, easy to use, rich in functions, suitable for various processing occasions.

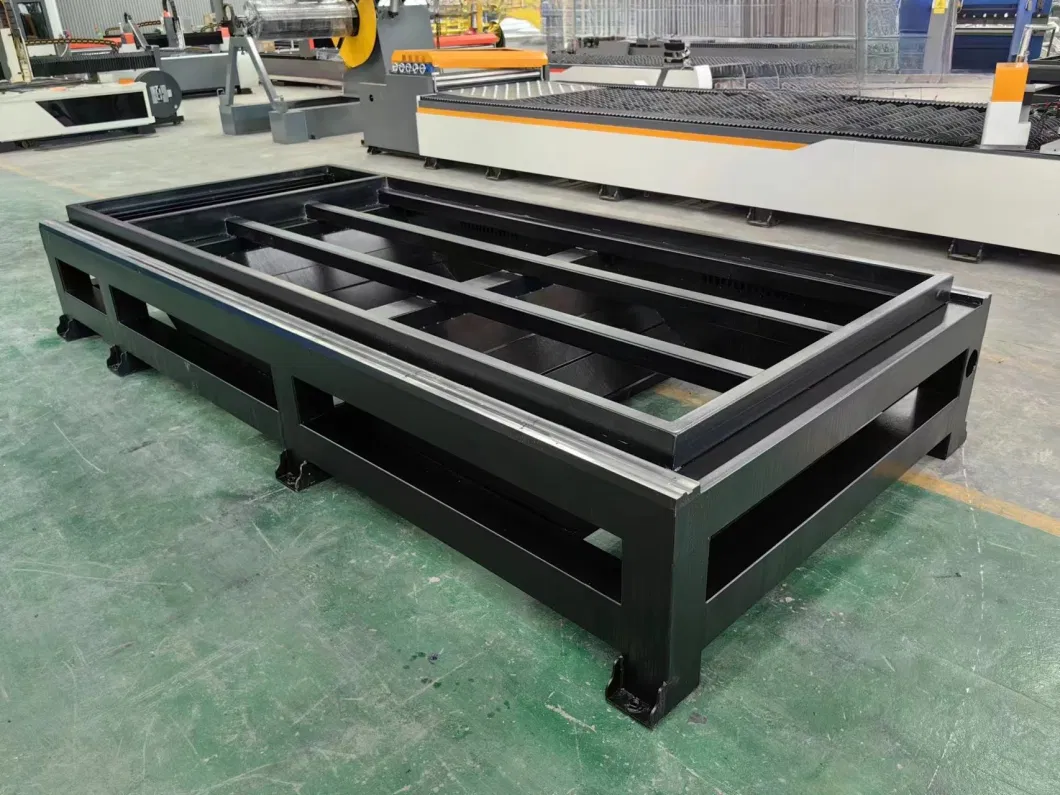

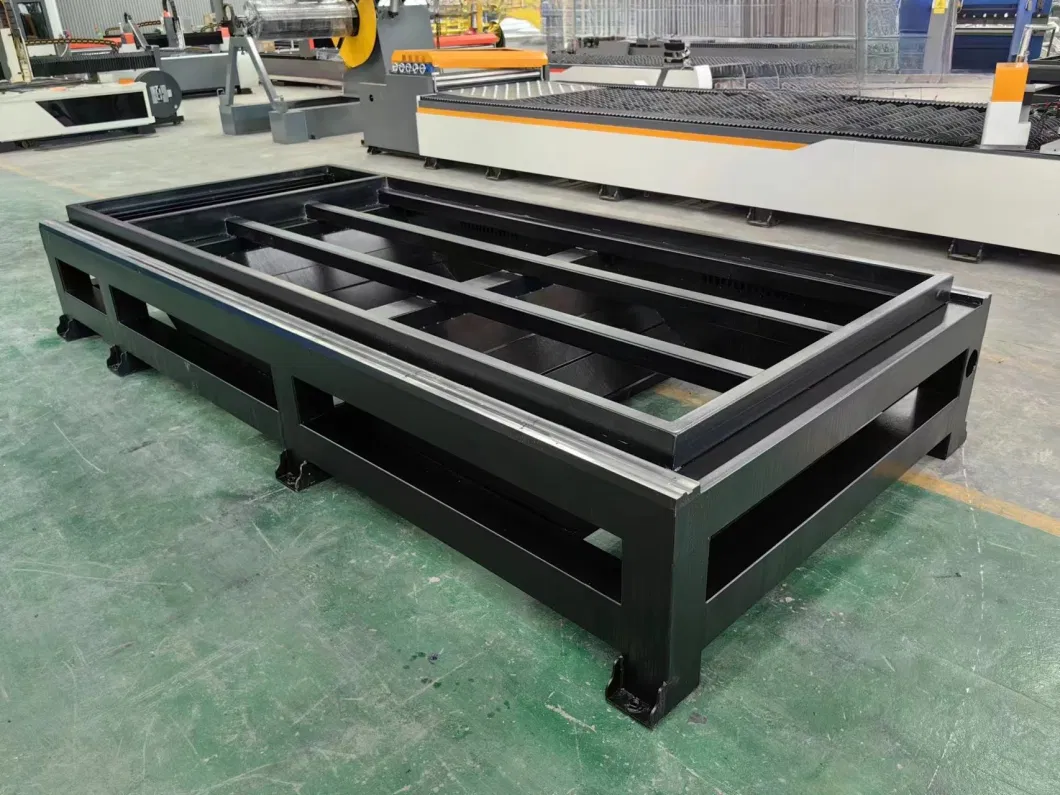

High precision bed

High quality square tube welding and three pass welding process are adopted, which are sturdy and durable. The structural materials are annealed at high temperature to eliminate internal stress, so that the machine bed can maintain good mechanical properties such as tensile strength, toughness, hardness and deformation resistance.