Basic Info.

Model NO.

hby2-15

Customized

Customized

Automatic Grade

Semiautomatic

Type

Hydraulic Shock

Block Type

Interlocking Bricks

Raw Material

Soil Cement Clay

Molding Cycle

15-20s

Total Weight

500kgs

Color

as Request

Brick Size

300*150*100mm

Transport Package

Normal Package

Specification

1600x820x1700mm

Trademark

hongbaoyuan

Origin

Shandong

HS Code

8474802000

Production Capacity

500 Sets/Year

Packaging & Delivery

Package Size

11.00cm * 22.00cm * 11.00cm

Package Gross Weight

450.000kg

Product Description

Eco Brava HBY2-15 Interlocking Soil Brick Making Machine Machinery

Brief introduction of HBY2-15 clay brick making machine

ECO BRB HBY2-15 brick making machine is our newest clay and cement soil brick making machine.

it is hydraulic pressure,easy operation.about 3000-4000 Bricks a day.The best choice for small factory to bulid small clay plant.diesel enginee or motor for your choose.

Features:

Capacity:

Using electric power,hby2-15 hydraulic electric motor interlocking brick making machine can produce more than 2600pcs blocks per shift. Shor shapping cycle 15s ensure a high level production capacity.

Function:

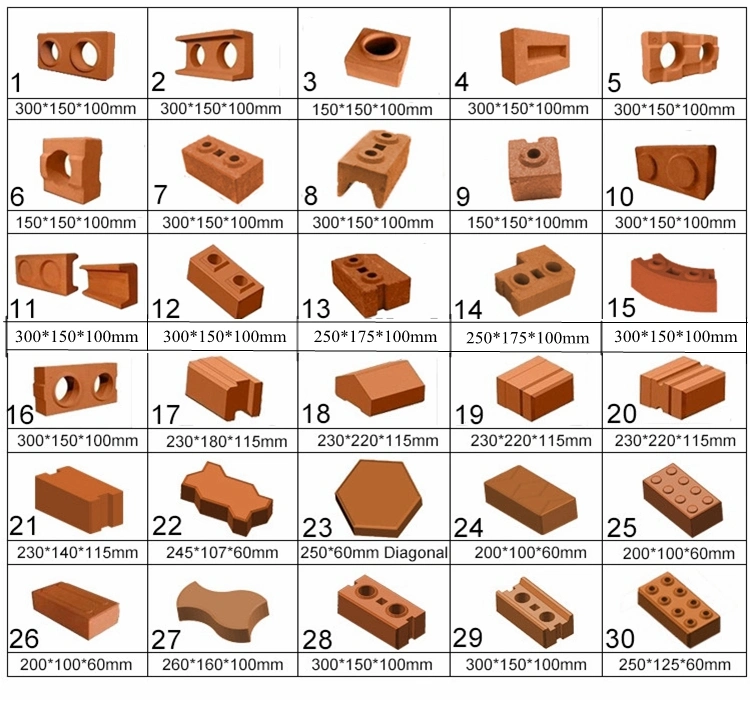

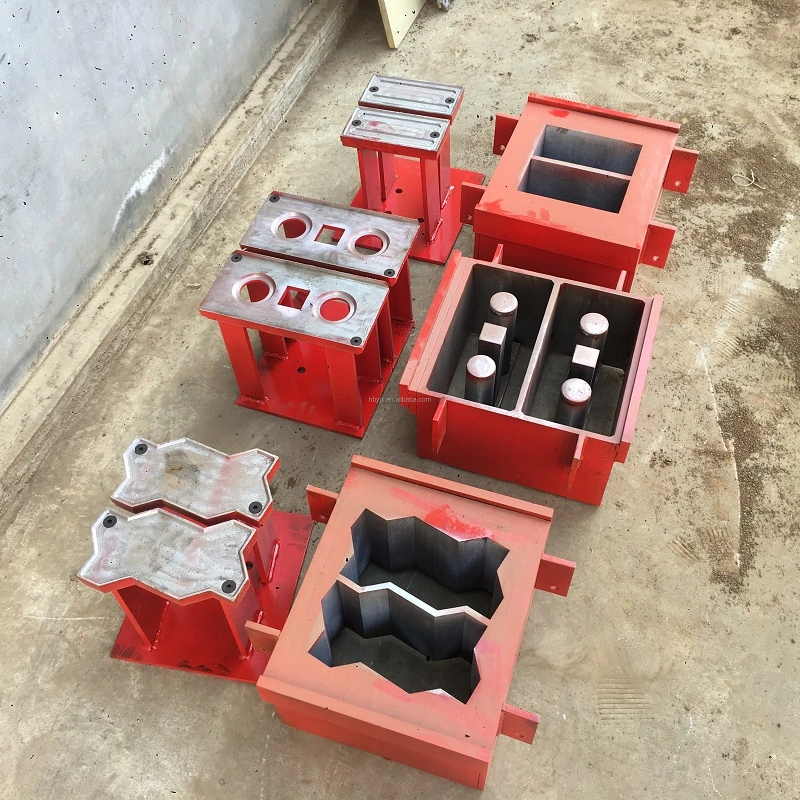

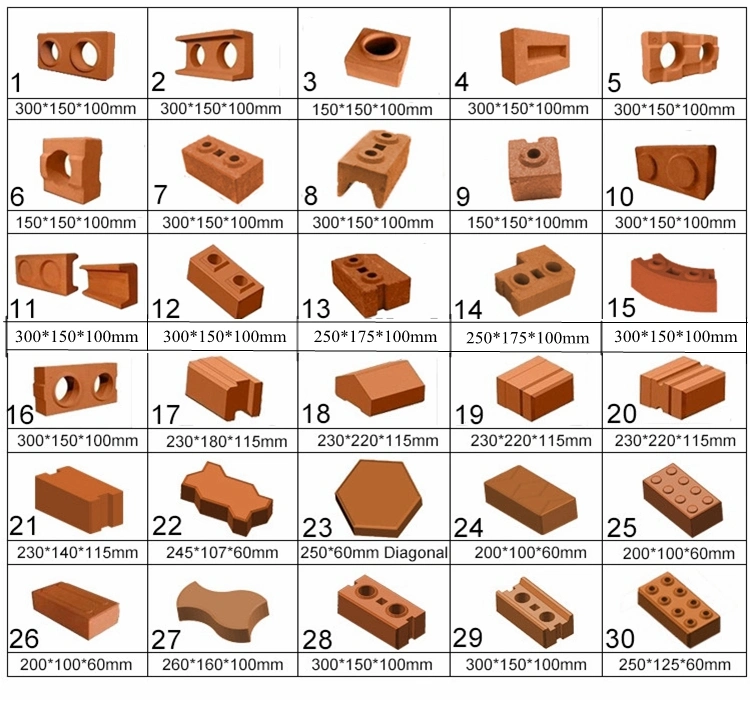

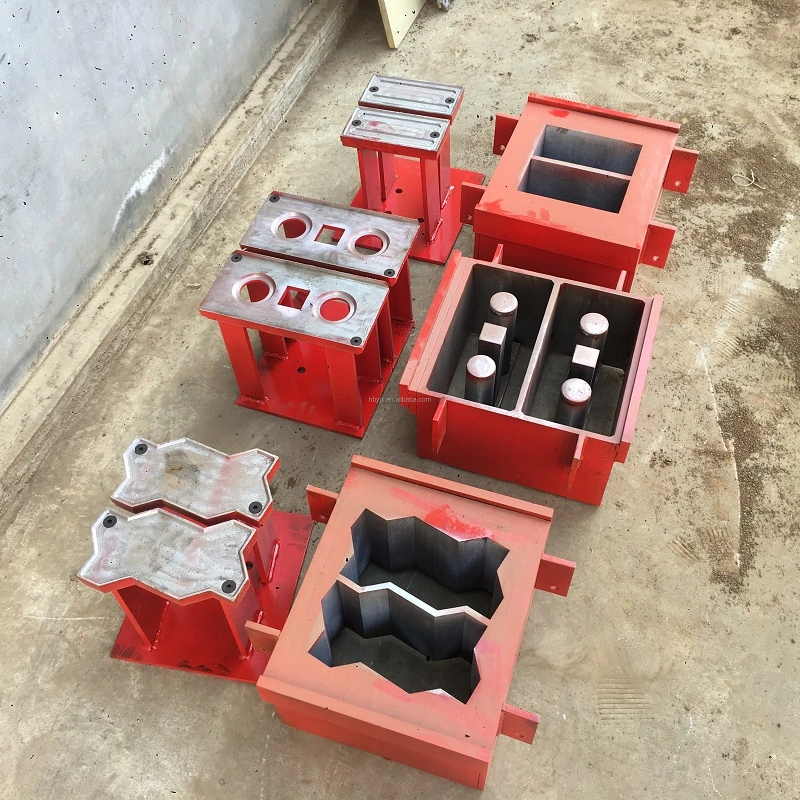

HBY2-15 interlocking block machine line can produce many kinds of block with different size just by changing the mould.

Moulding technology:

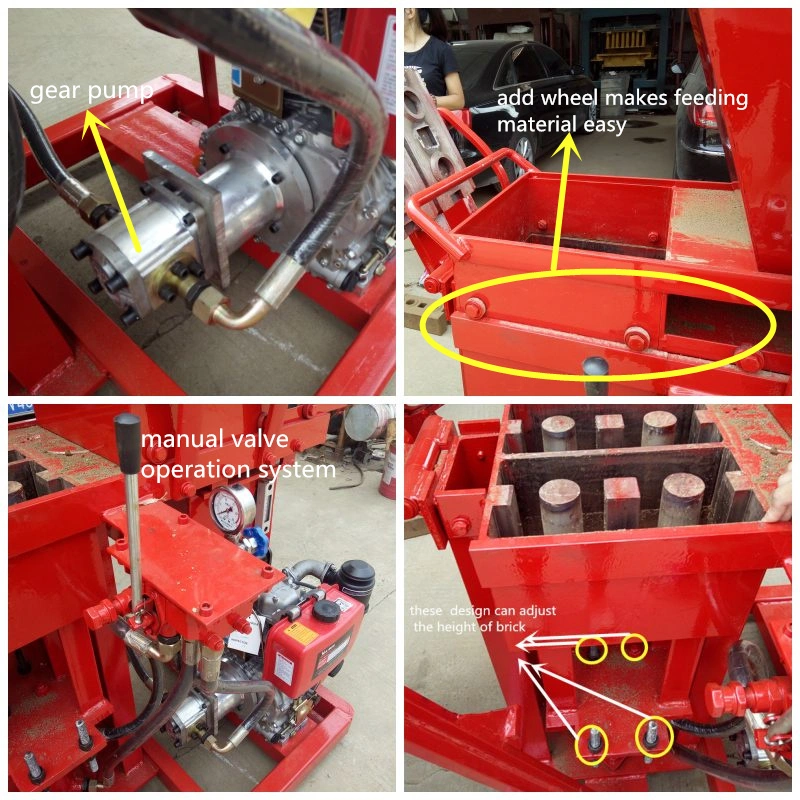

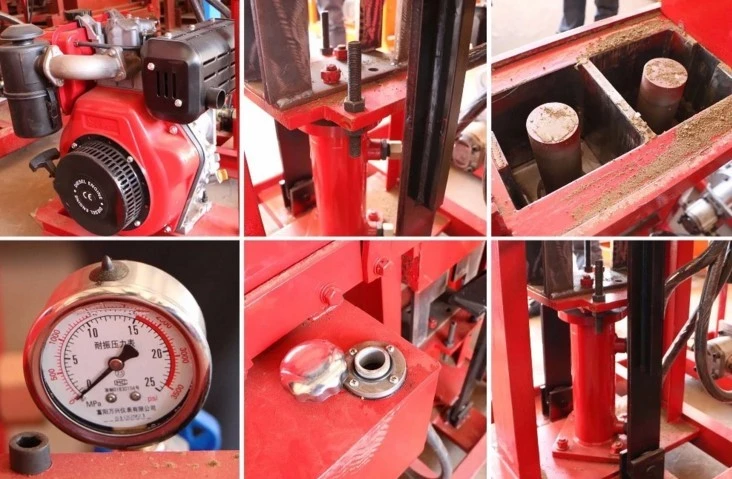

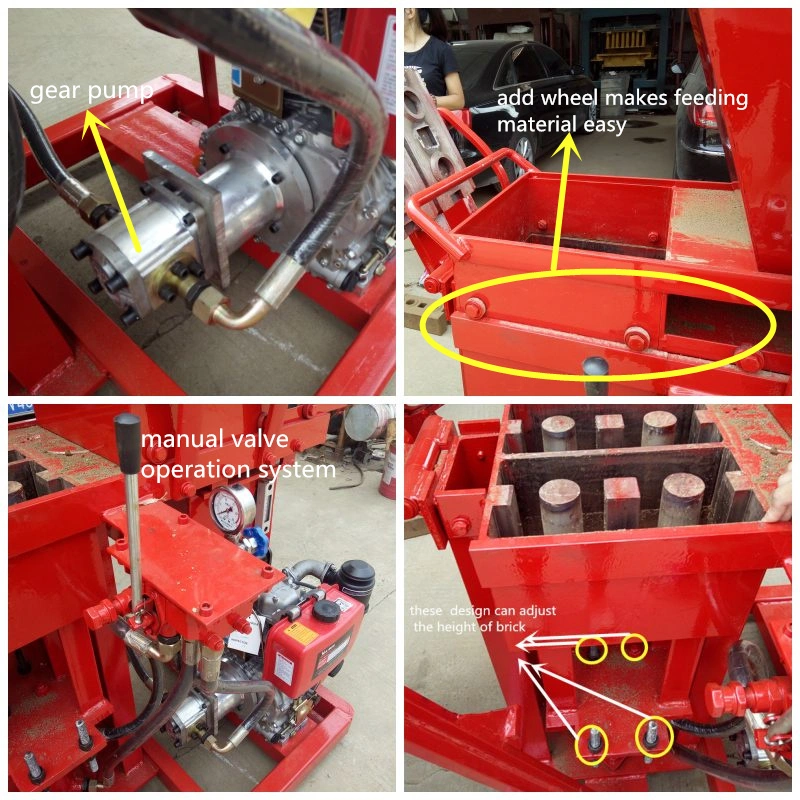

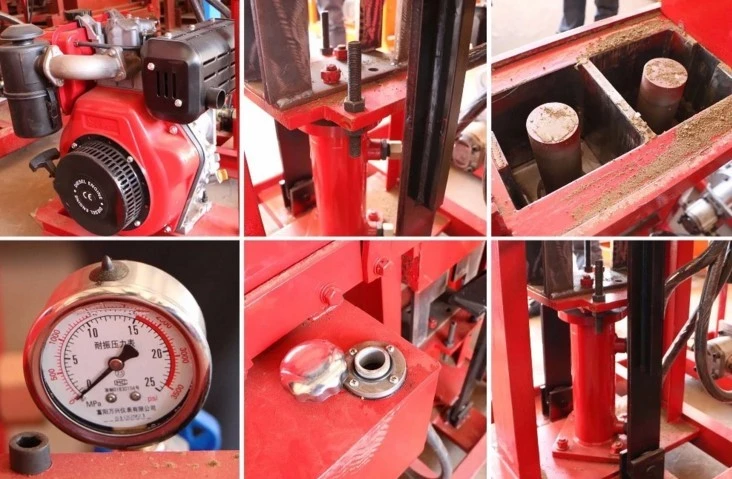

hby2-15 adopts hydraulic moulding technology which can ensure the firmness and precise of the blocks. What's more, precise line cutting technology and curburizing heat treatment technology are used in making the block moulds.

Using electric power,hby2-15 hydraulic electric motor interlocking brick making machine can produce more than 2600pcs blocks per shift. Shor shapping cycle 15s ensure a high level production capacity.

Function:

HBY2-15 interlocking block machine line can produce many kinds of block with different size just by changing the mould.

Moulding technology:

hby2-15 adopts hydraulic moulding technology which can ensure the firmness and precise of the blocks. What's more, precise line cutting technology and curburizing heat treatment technology are used in making the block moulds.

Advatange of our hby2-15 soil brick making machine

1) Hydraulic pressure ,makes the brick high density and stronger.

2) Automatic production.Automatic feeding material ,automatic press and automatic brick out .

3) Easy to operate,only need one hour trainning for this machine.

4) Easy to maintaince,all the parts in the outside ,so very easy to maintaince ,

5) Vulnerable parts supply. hand valves and oil lines will be supply for free.

| Technical Specifications | |

| Model | HBY2-15 interlocking brick machine |

| Standard | GB/T8533-2008 |

| Forming cycle | 15-25s |

| Pcs/mould | 2 pcs |

| Capacity | 3000-4000 pcs/8hour |

| Power | 5.5KW OR DIESEL ENGINE |

| Hydraulic pressure | 16-20 Mpa |

| Dimension | 1600x820x1700mm |

| Weight | 400kg |

| Brick material | Clay, soil, cement, concrete, fly ash and so on. |

| Block size | Pcs/mould | Pcs/hour | Pcs/8hours |

| 300*150*100mm | 2 | 400-600 | 3000-4000 |

| 250*125*75mm | 2 | 400-600 | 3000-4000 |

| 150*150*100mm | 4 | 800-1200 | 5000-7000 |

| 200*100*60mm | 2 | 400-600 | 3000-4000 |

Differnet types of interlocking bricks can produce by our machine

Different moulds of our block making machine

Package of HBY2-15 interlocking brick machine

Feedback from our Customers:

our customer from all over the world such as Congo, Ghana,Guatemala, Haiti, Jamaica, Mexico, Peru,

Chile, Ghana, South Africa, Zimbabwe, Botswana, Cote d'Ivoire, Cameroon, Kenya, Tanzania, Egypt,

Saudi Arabia, UAE, Philippines and more than 90 countries.

We Hongbaoyuan machinery are engaged in manufacturing and supplying a high class array of Block and Brick Making Machines.

Under the offered array, we have Concrete Block Making Machine,Interlocking Brick Making Machine and

Diesel Engine Brick Making Machine. The demand of offered machines are rising as these ensure reliable performance,

have sturdy construction and require minimum maintenance.

To ensure that our offered machines have listed below features, we manufacture these using optimum quality

raw material with the assistance of experts.

Welcome to visit our factory.

FAQ:

Q1. What is your terms of packing?

A: Plywood box for Less than one container. Nude package for Full container OR AS CUSTOMER REQUEST

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

Q4. How about your delivery time?

A: Generally, it will take 15-20 days after receiving your advance payment.

Q5. Q: What is the life span of your machine?

A:usually 8-10 years

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.