Basic Info.

Model NO.

1500W 2000W

Technical Class

Continuous Wave Laser

Control

Automatic

Power Density

Heat Conduct Welding

Laser Classification

Optical Fiber Laser

Type

Optical Fiber Transmission Laser Welding Machine

Welding Materials

Metal

Working Voltage

220V

Welding Machine

1500W 1000W

Laser Source

Raycus/Max

Portable Laser Welder

1000W 2000W

Applicable Industries

Metal Welding

Heat Conduct Welding

Laser Power

Aiming and Positioning

CCD and Red Right

Laser Machine

Fiber Laser Welder

Cooling System

Water Cooling

Laser Power

1000W, 1500W, 2000W

Indicating System

Red Light

H.S Code

8515809090

Laser Welder

1000W, 1500W, 2000W

Welding Gap Requirements

Cabinet/Portable

Transport Package

Wooden Box

Specification

1500W

Trademark

ALLWIN tech

Origin

China

HS Code

8456909000

Production Capacity

1500

Packaging & Delivery

Package Size

162.00cm * 95.00cm * 160.00cm

Package Gross Weight

280.000kg

Product Description

What main parts including for wobble laser head fiber laser welding machine?

1000W 1500W 2000W Portable Handheld Fiber laser welding machine for Metal Titanium Alloy Aluminum Brass

It is composed of laser generator, refrigeration system, control system, handheld welding head and wire feeder.

Using the latest generation of fiber laser, equipped with the welding head independently developed by our company,

filling the blank of handheld welding in the laser equipment industry,

it has the advantages of simple operation, beautiful welding seam, fast welding speed and no consumables.

It is used in thin stainless steel, iron, For welding of metal materials such as galvanized sheet,

it can perfectly replace traditional argon arc welding, electric welding and other processes.

The handheld laser welding machine can be widely used in the complicated and irregular welding processes of cabinets, kitchens and bathrooms, stair elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel home appliances and other industries.

Model features:

★High energy density, low heat input, small amount of thermal deformation, and narrow melting depth in the heat and heat affected zone of the melting zone.

★The cooling rate is high, so that the weld structure can be fine and the joint performance is good.

★ Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly improving work efficiency.

★The weld is fine, the penetration is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

★ No consumables, small size, flexible processing, low operating and maintenance costs

★The laser is transmitted through the optical fiber and can work with the assembly line or the robot.

★ The touch switch is equipped with a safety clip, and the laser beam can only be emitted when the welding nozzle touches the metal.

★ Red light positioning is used to verify the position during welding.

LASER WELDING SOURCE

IPG FIBER LASER WELDING SOURCE AND WATER CHILLER

IPG FIBER LASER WELDING SOURCE AND WATER CHILLER

LASER HEAD

LASER HEAD

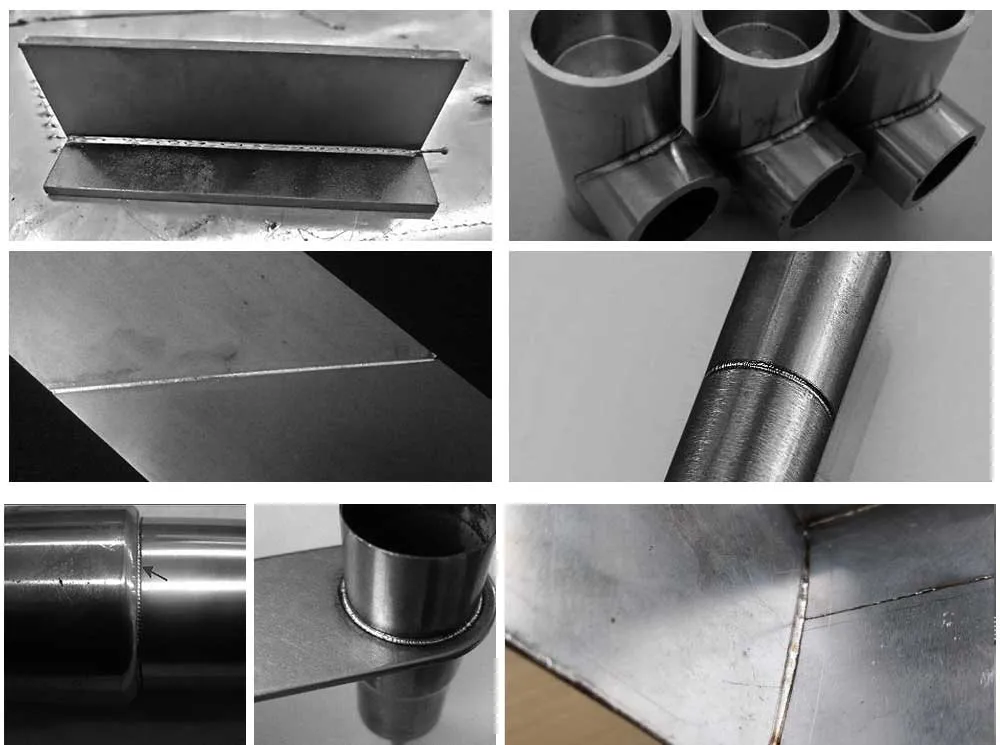

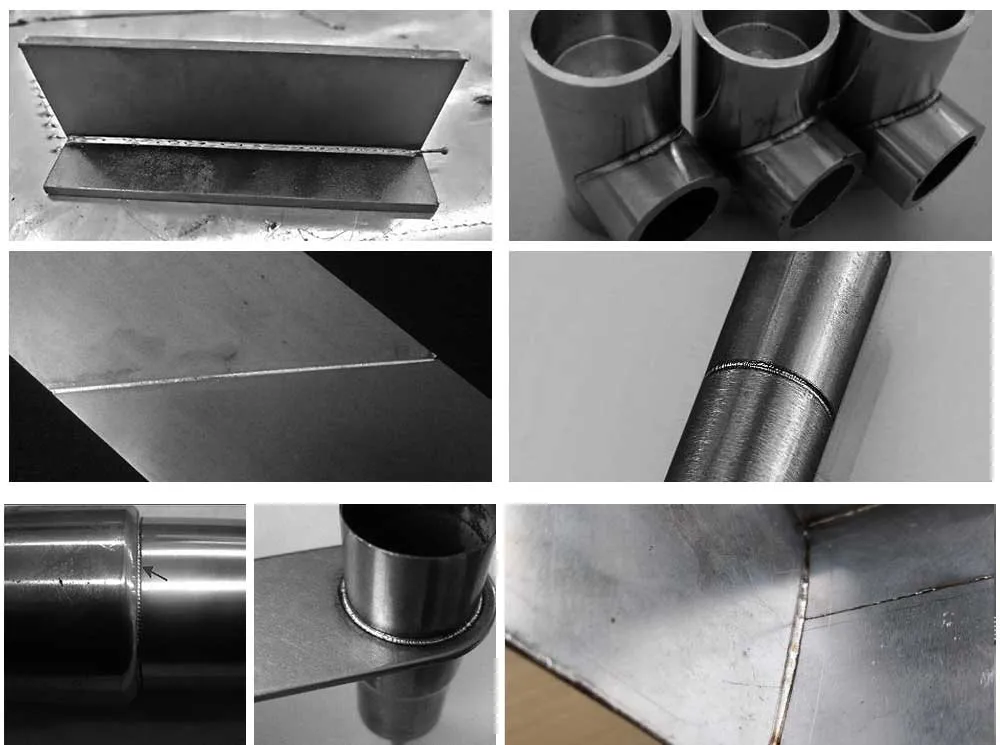

what material can be welding and what subjects does portable laser welding machine could finish?

Aluminum,Stainless Steel, Carbon Steel, Copper,Silver, Titanium, Tin .

Comparison of handheld laser welding and argon arc welding:

1. Energy consumption comparison: Compared with traditional arc welding, hand-held laser welding machine saves about 80%~90% of electric energy, and the processing cost can be reduced by about 30%.

2. Welding effect comparison: laser hand-held welding can complete dissimilar steel and dissimilar metal welding. The speed is fast, the deformation is small, and the heat affected zone is small. The weld seam is beautiful, smooth, no/less porosity, and no pollution. The hand-held laser welding machine can perform micro-small parts and precision welding.

3. Comparison of follow-up processes:

When laser hand-held welding, the heat input is low, the deformation of the workpiece is small, and the beautiful welding surface can be obtained without or only simple treatment (depending on the requirements of the welding surface effect). The handheld laser welding machine can greatly reduce the labor cost of the huge polishing and leveling process.

1000W 1500W 2000W Portable Handheld Fiber laser welding machine for Metal Titanium Alloy Aluminum Brass

It is composed of laser generator, refrigeration system, control system, handheld welding head and wire feeder.

Using the latest generation of fiber laser, equipped with the welding head independently developed by our company,

filling the blank of handheld welding in the laser equipment industry,

it has the advantages of simple operation, beautiful welding seam, fast welding speed and no consumables.

It is used in thin stainless steel, iron, For welding of metal materials such as galvanized sheet,

it can perfectly replace traditional argon arc welding, electric welding and other processes.

The handheld laser welding machine can be widely used in the complicated and irregular welding processes of cabinets, kitchens and bathrooms, stair elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel home appliances and other industries.

Model features:

★High energy density, low heat input, small amount of thermal deformation, and narrow melting depth in the heat and heat affected zone of the melting zone.

★The cooling rate is high, so that the weld structure can be fine and the joint performance is good.

★ Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly improving work efficiency.

★The weld is fine, the penetration is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

★ No consumables, small size, flexible processing, low operating and maintenance costs

★The laser is transmitted through the optical fiber and can work with the assembly line or the robot.

★ The touch switch is equipped with a safety clip, and the laser beam can only be emitted when the welding nozzle touches the metal.

★ Red light positioning is used to verify the position during welding.

LASER WELDING SOURCE

IPG FIBER LASER WELDING SOURCE AND WATER CHILLER

IPG FIBER LASER WELDING SOURCE AND WATER CHILLER LASER HEAD

LASER HEAD

Compared with Other Welding(What advantage for Fiber laser welding machine)

| Comparison item | Traditional welding | Laser welding | laser new generation laser welding |

| Heat input to the workpiece | Very high | Low | Low |

| Deformation of the workpiece, undercut | Big | Small | Small |

| Bond strength with base material | Generally | Good | Very good |

| Subsequent processing | Polished | No sanding, or little sanding | No sanding, or little sanding |

| Welding speed | Generally | More than 2 times of argon arc welding | More than 2 times of argon arc welding |

| Applicable materials | Stainless steel. Carbon steel. Galvanized sheet | Stainless steel. Carbon steel. Galvanized sheet | Stainless steel. Carbon steel. Galvanized sheet |

| Consumables | Many consumables | Less consumables | Less consumables |

| Operation difficulty | Complex | Generally | Simple |

| Operator safety | Not safe | Safety | Safety |

| Environmental protection impact | Not environmentally friendly | Environmental Protection | Environmental Protection |

| Welding fault tolerance | Good | Not good | Good |

| Weaving welding | None | None | Have |

| Adjustable light spot width | None | None | Have |

| Welding quality comparison | Difference | Generally | Very good |

Characteristic for portable handheld laser weding machine 2000W,1500W,1000W

Basic features: self-developed control system, set multiple safety alarms, smaller size, flexible operation and easy to use.

More stable: All parameters are visible, real-time monitoring of the status of the whole machine, to avoid problems in advance, more convenient to troubleshoot and solve problems, to ensure the stable operation of the welding head.

Process: All parameters are visible, the welding quality is more perfect, the deformation is small, and the penetration is high. Stable parameters and high repeatability: the determined nozzle air pressure and lens state, as long as the laser power is stable, the process parameters must be repeatable. Greatly improve efficiency, while also reducing operator requirements

Basic features: self-developed control system, set multiple safety alarms, smaller size, flexible operation and easy to use.

More stable: All parameters are visible, real-time monitoring of the status of the whole machine, to avoid problems in advance, more convenient to troubleshoot and solve problems, to ensure the stable operation of the welding head.

Process: All parameters are visible, the welding quality is more perfect, the deformation is small, and the penetration is high. Stable parameters and high repeatability: the determined nozzle air pressure and lens state, as long as the laser power is stable, the process parameters must be repeatable. Greatly improve efficiency, while also reducing operator requirements

| 2.2 Operating Environment and Parameters | |

| Supply voltage (V) | 220±10% V AC 50/60Hz |

| Place the environment | Flat, no vibration and shock |

| Working environment temperature (°C) | 10 40 |

| Working environment humidity (%) | <70 |

| Cooling method | Water cooling |

| Applicable wavelength | 1064nm (+10nm) |

| Applicable power | ≤2000W |

| Collimation | D20*5/F60 |

| Focus | D20*4.5/F150 |

| Reflection | 30*14 T2 |

| Protective lens specifications | 18*2 |

| Maximum supported air pressure | 10 bar |

| Focus vertical adjustment range | ±10mm |

| Spot adjustment range | Line 0-5mm |

| Weight | SUP 15S 1. 25KG/SUP 20S 0.8KG |

Aluminum,Stainless Steel, Carbon Steel, Copper,Silver, Titanium, Tin .

Comparison of handheld laser welding and argon arc welding:

1. Energy consumption comparison: Compared with traditional arc welding, hand-held laser welding machine saves about 80%~90% of electric energy, and the processing cost can be reduced by about 30%.

2. Welding effect comparison: laser hand-held welding can complete dissimilar steel and dissimilar metal welding. The speed is fast, the deformation is small, and the heat affected zone is small. The weld seam is beautiful, smooth, no/less porosity, and no pollution. The hand-held laser welding machine can perform micro-small parts and precision welding.

3. Comparison of follow-up processes:

When laser hand-held welding, the heat input is low, the deformation of the workpiece is small, and the beautiful welding surface can be obtained without or only simple treatment (depending on the requirements of the welding surface effect). The handheld laser welding machine can greatly reduce the labor cost of the huge polishing and leveling process.