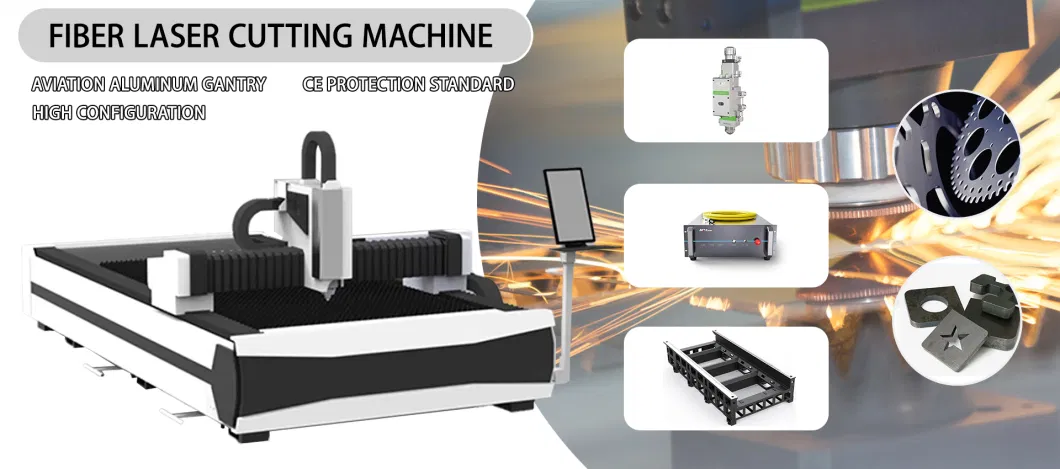

- Overview

- Product Description

- Detailed Photos

- Product Parameters

- Product Applications

- Production Process

- Packaging & Shipping

- Our factory and Our advantage

- Our CE and Our partners

Basic Info.

Packaging & Delivery

Product Description

Laser Source

- Raycus/Ipg/Max/Reci(Selectable)

- Over 100000 hours lifetime

- Low energy cost

- High electro-optical conversion rate

Laser Cutting Head

- Optimized optical configuration and smooth and efficient airflow design significantly improve cutting quality and efficiency

- Automatic focusing, reducing human intervention, automatic focusing*range-12~+10mm, focusing accuracy 0.05mm

- Increase the nozzle cooling airflow, effectively protect the nozzle and ceramic body, and prolong the continuous working time

- Quick and easy replacement of protective lenses

2.Quenching and tempering process to prevent deformation,reduce vibration, and make the processing accuracy higher

4.30 days eliminating stress through welding

- Aviation grade aluminum through extrusion

- Light weight

2.Easy to operate, fully automated system;With various functions, it is easy to complete complex designs

3.Self-contained database, no need to adjust parameters by yourself

Water cooler

2. Stabilize the light output rate of the laser, and prolong the service life of the laser

2. High quality, not easy to deform, make the machine run more smoothly and stronger.

Servo

2. Servo Driver: YASKAWA

3.Faster acceleration and higher processing efficiency

| Model | HY6025s | ||

| Laser Power | 3000W | 6000W | 12000w |

| Max. Cutting Thickness | 20 mm | 25 mm | 30mm |

| Laser Source | MAX | ||

| Laser Head | BM110 | ||

| Working area | 3000*1500 mm | ||

| X axis Stroke | 3020 mm | ||

| Y axis Stroke | 1520 mm | ||

| Z axis Stroke | 150 mm | ||

| Transmission way | Imported Japan THK ball screw | ||

| Table-driven system | Delta | ||

| Focus Method | Dynamic Following and Automatic Adjust Focus | ||

| Location precision | ≤±0.05 mm | ||

| Re-location precision | ±0.02 mm | ||

| Max. moving speed | 100m/min | ||

| Laser wavelength | 1070nm | ||

| Minimum line width | ≤0.1mm | ||

| Supporting Format | PLT, DXF, BMP, AI ,CNC | ||

| Power demand | 380V/50HZ | ||

| Worktable max. load | 5000 Kg | ||

| Dimension (L*W*H) | 4100mmX2200mmX1700mm | ||

| Control Method | offline movement Control | ||

| Control software | Raytools XC3000 | ||

Cutting parameter

This machine can be used for different materials, such as carbon steel, stainless steel, galvanized sheet, copper, aluminum, and so on. And it has multiple uses

Shandong HOYSOOK Laser Technology CO.,Ltd is a high-tech enterprise in laser manufacturing industry. We provide professional one-stop laser manufacturing application solutions, including laser cutting, welding, cladding, marking and so on. Our main product: laser cutting machine, laser welding machine and laser marking machine.Over 30 years of development, we adhere to independent innovation, has obtained a number of patents, and get the European Union CE certification.

Installation and debugging

Technicians can be sent to the factory for training (free of service fee for the first time). Customers only need to provide accommodation for engineers.

Training

Free of charge for training within warranty. But customers need to take charge of the cost for accommodation, air tickets, visa fee.

24/7 online service

All our laser equipment is provided with 12 months warranty. Hoysook Laser offers free maintenance or replacement service if something is wrong with the equipment under warranty.

Accessories supply

Laser source warranty is 2 years. Other parts is 3 years except for optical and consumable parts.

Q: Do you have CE document and other documents for customs clearance?

A: Yes, we have CE, provide you with a one-stop service. We would like to provide any documents for your custom.

Q: If we are interested in your machine, how to choose ?

A:Please tell us these infomation ,we will recommend the best solution to you

1) Your materials

2) Max size of your material

3) Max cut thickness

Q: How about warranty?

A: 3 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.

Q :Our workers can't operate the machine, how to train the staff?

A:We will send you the teaching video of the machine and 24-hour online service,

we also support free training service, engineers can train your workers for free in our factory for 1-3 days

If you want door-to-door service,We can arrange local service in 48 hours

Q :It's not convenient for me to go to China, but I want to see the condition of the machine in the factory. What should I do?

A:We support the production visualization service. You can check our factory and machine condition by video.