Basic Info.

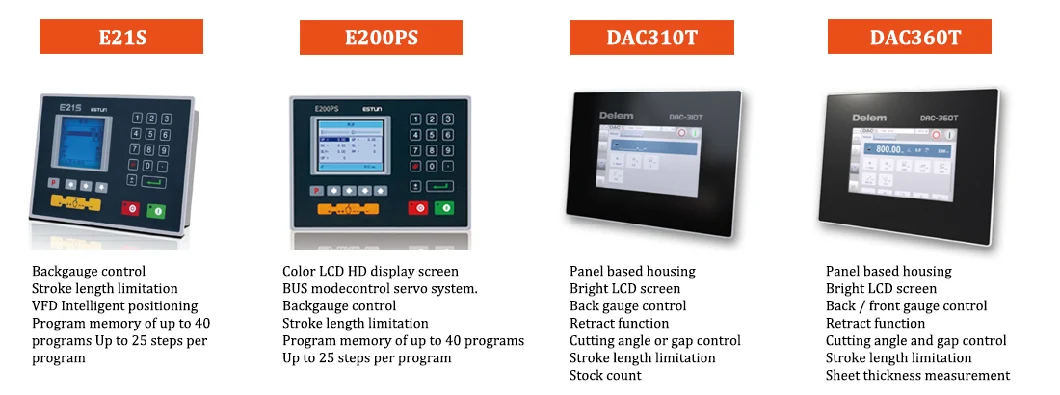

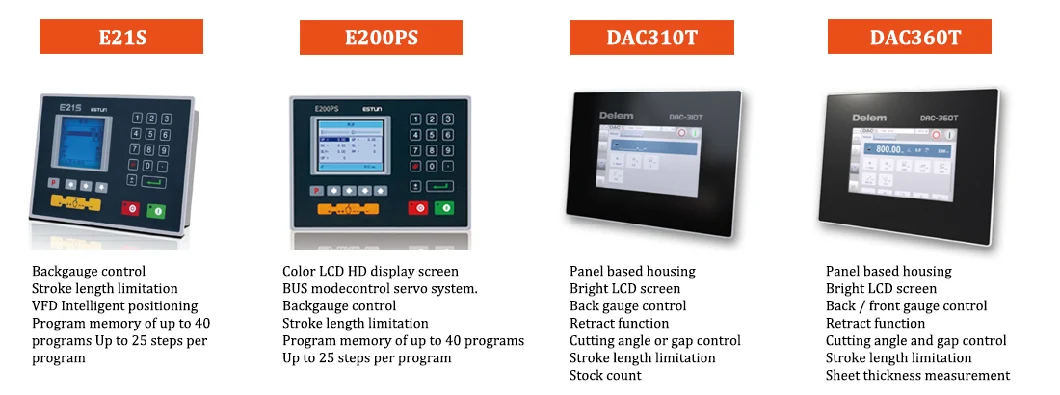

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

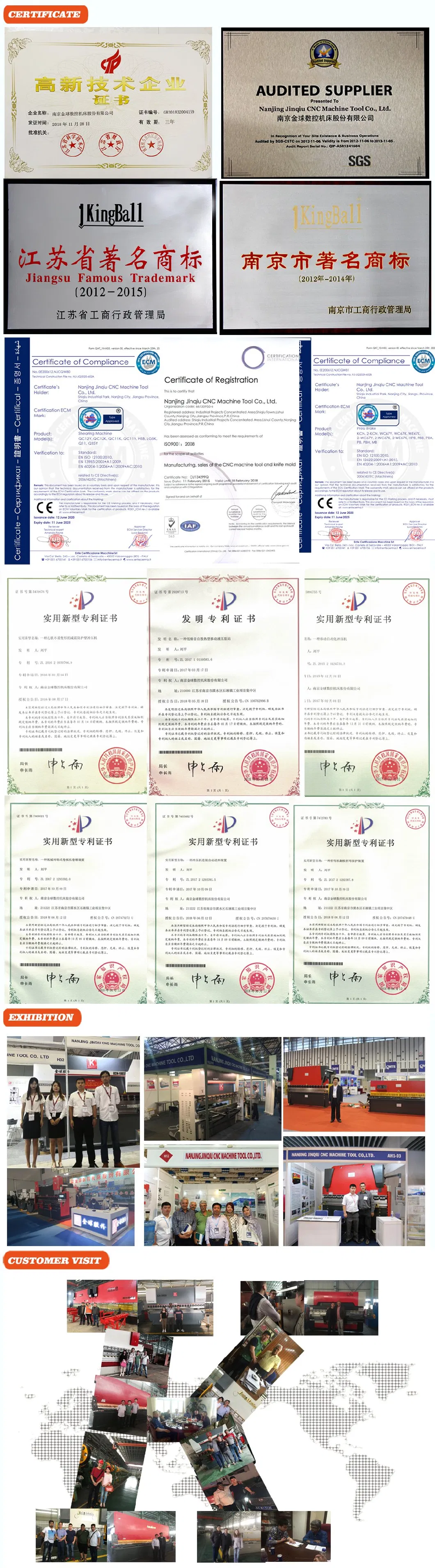

Certification

GS, CE, ISO 9001

Condition

New

Nanjing City

Jiangsu Province

Transport Package

Plastic

Specification

QC12Y-4X2500

Trademark

KINGBALL

Origin

China

HS Code

8462399000

Production Capacity

100

Product Description

Products Description

Details Images

2.Welded steel plate construction, heating to eliminate stress,with high strength and good rigidity.

3.Advanced integrated hydraulic system with and excellent reliabitity quality.

4.Rapidly,accurately and conveniently adjusting the blade clearance by motor

5.The adjustable rake angle can minimize plate deformation.

6.As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed.

7.Shearing in sections,shadow-line cutting.

8.Counter for the motorized back gauge.

9.Back support device (optional).

Our Service

Our Service

FAQ

1.Can you supply the relevant documentation?

| Hydraulic Guillotine Shearing Machine | QC11Y-16X2500 | QC11Y-16X3200 | QC11Y-16X4000 | QC11Y-16X5000 | QC11Y-16X6000 |

| Cutting Thickness (mm) | 16 | 16 | 16 | 16 | 16 |

| Cutting Width (mm) | 2500 | 3200 | 4000 | 5000 | 6000 |

| Throat Depth (mm) | 100 | 100 | 100 | 100 | 100 |

| Cutting Angle ( o) | 0.5°-2°30′ | 0.5°-2°30′ | 0.5°-2°30′ | 0.5°-3° | 0.5°-3° |

| Backgauge Range (mm) | 20-800 | 20-800 | 20-800 | 20-1000 | 20-1000 |

| Stroke Number (times/min) | ≥6 | ≥5 | ≥5 | ≥5 | ≥4 |

| Main Motor (kw) | 18.5 | 18.5 | 18.5 | 22 | 22 |

| Weight (kg) | 9500 | 12000 | 16500 | 25000 | 35000 |

| Overall Dimensions (LxWxH in mm) | 3215x1970x2340 | 3915x1970x2455 | 4715x2010x2590 | 6000x2300x3000 | 7250x2400x3100 |

Details Images

QC11Y(K) Series CNC Hydraulic Guillotine Shearing Machine

Main functions and features

1.The second generation of shear.2.Welded steel plate construction, heating to eliminate stress,with high strength and good rigidity.

3.Advanced integrated hydraulic system with and excellent reliabitity quality.

4.Rapidly,accurately and conveniently adjusting the blade clearance by motor

5.The adjustable rake angle can minimize plate deformation.

6.As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed.

7.Shearing in sections,shadow-line cutting.

8.Counter for the motorized back gauge.

9.Back support device (optional).

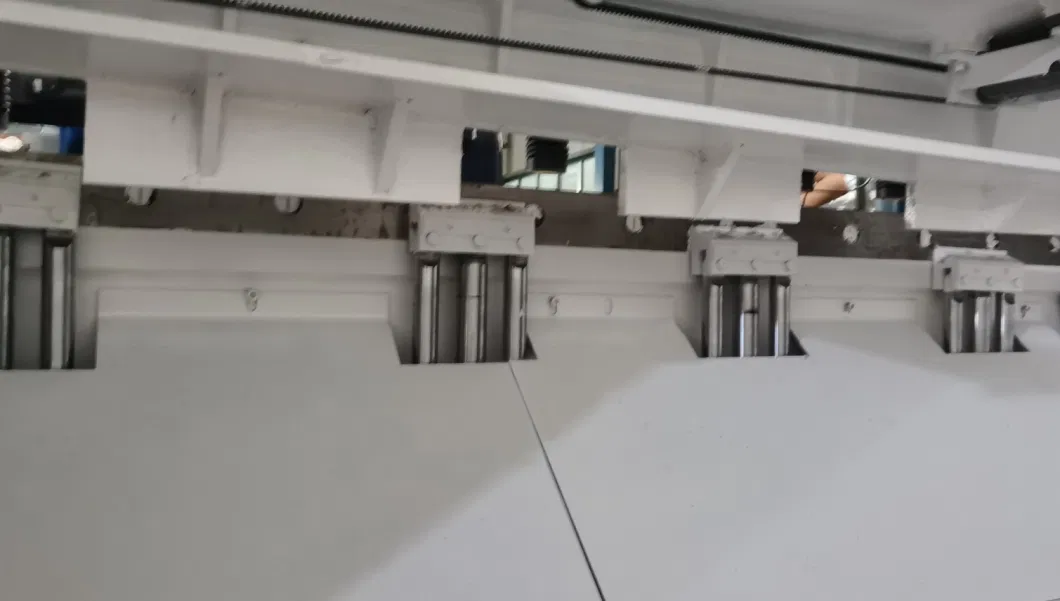

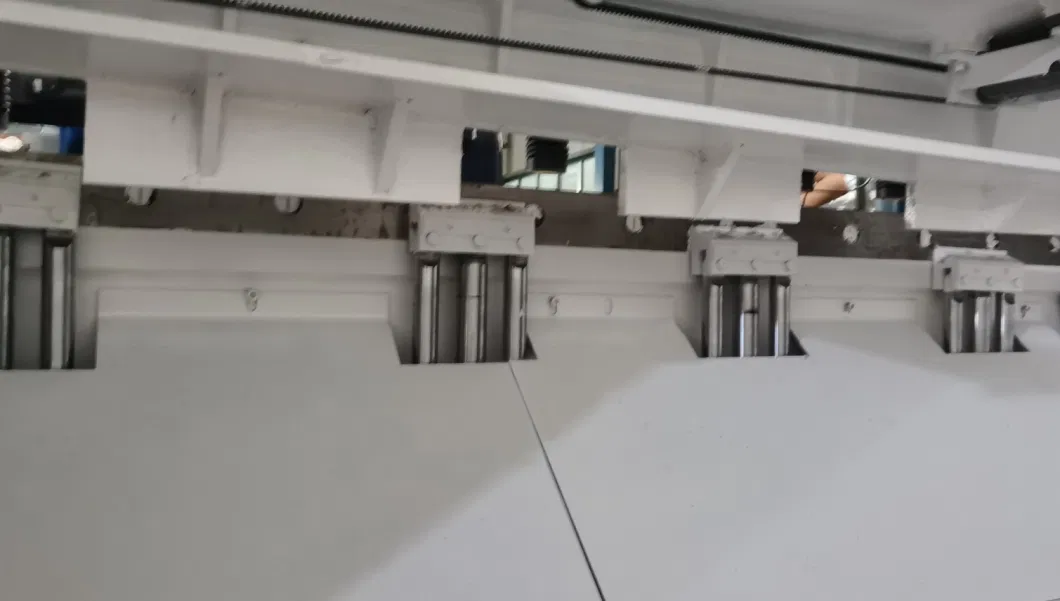

Pneumatic Sheet Support System

Monobloc Panel Type support system:

Avoids hanging down the wide and thin sheets via pneumatic table support and provides more precise cuts.

Avoids hanging down the wide and thin sheets via pneumatic table support and provides more precise cuts.

Anti-twist System

Anti-twist system contrasts the piece warping by pushing it against the upper blade.

The unique Anti-Twist system of kingball guillotine shears consists of a series of hydraulic cylinders placed below the lower

blade, which support the sheet metal against the upper blade.

The cylinders exert a counter-pressure in proportion to the thickness, thus compensating the twist effect of the sheet.

The unique Anti-Twist system of kingball guillotine shears consists of a series of hydraulic cylinders placed below the lower

blade, which support the sheet metal against the upper blade.

The cylinders exert a counter-pressure in proportion to the thickness, thus compensating the twist effect of the sheet.

Front Feeding Table

Feeding the metal sheet automatically controlled by PLC ,the precision of the feeder is more accurate

The clamp adopts pneumatic clamp, which has reliable supporting power, wide processing range and convenient operation.

The clamp adopts pneumatic clamp, which has reliable supporting power, wide processing range and convenient operation.

Our Service

Our Service Pre-sales services:

1. inquiry and consulting support

2. sample testing support

3. visit our factory

After-sales services:

1. 2 years warranty period

2. training how to install and use the brake press machine

3. engineers available to service machinery

overseas

overseas

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis/Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days.

2.What is the average lead time?

For samples, the lead time is about 7 days.

For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products.

If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.

4.What is the product warranty?

We warranty our materials and workmanship.

accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.

4.What is the product warranty?

We warranty our materials and workmanship.

Our commitment is to your satisfaction with our products. In warranty or not, it is the

culture of our company to address and resolve all customer issues to everyone's satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging.

culture of our company to address and resolve all customer issues to everyone's satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging.

We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items.

Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way.

By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of

amount, weight and way. Please contact us for further information.

amount, weight and way. Please contact us for further information.