Basic Info.

Product Description

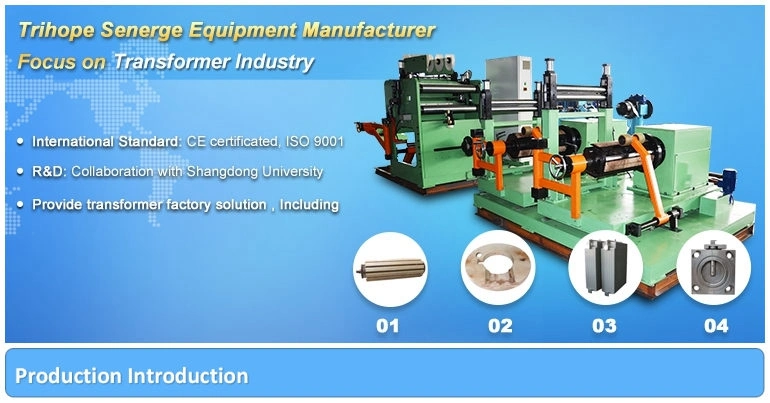

Paperboard Less Than 3mm Thickness Automatic Feeding Shearing Machine

Paperboard Less Than 3mm Thickness Automatic Feeding Shearing Machine Insulating Pressboard Automatic Feeding Shearing Machine is mainly used for shearing of insulating pressboard with high accuracy in the transformer industry. Material is fed automatically with CNC control. The required size can be automatically cut out by inputting the required shear width and dimensions for both ends through the touch screen to improve the shearing accuracy and efficiency.

Main Technical Parameters for Insulating Pressboard processing machine

(1) Maximum shear plate thickness (mm) : 3

(2) Maximum shear plate width (mm) : 2500

(3) Maximum feeding length (mm): 2400

(4) Stokes times: up to 30 times/min

(5) Shearing blade material: 9CrSi

(6) Shearing burr: Max. 0.1mm when the pressboard thickness at 1mm

(7) Control Panel: zhongkong youda

(8)Main electrical components: Schneider

(9) After the parameters are input through the touch screen, the feeding is automatic and the feeding accuracy is ±0.2mm for the rectangular strip, and the Feeding accuracy is ±0.5mm when shear the wedge-shape strip. The equipment also keeps the manual feeding option. The width of tail material is about 100mm after feeding, which can be used for other purposes.

(10) Shear shape of the strip: Rectangular strip, or Wedge-shape strip.

(11) The shearing blade is convenient to disassemble for grinding.