Basic Info.

Model NO.

KSDC-8609

Air Volume

8000 ± 300m³ / H

Treatment of Air Flow

6500m3/H

Motor Power

7.5kw

Voltage

380V/50Hz or 460V/60Hz

Filtering Material

Polyester +PTFE

Filtering Area

135m³

Filter Cartridge

9PCS

Cleaning Way

Atomatic Cleaning

Noise

≤75±5dB a

Weight

1420±20kgs

Transport Package

Wooden Case

Specification

1800*2000*2500mm

Trademark

Kaisen

Origin

Shanghai, China

HS Code

8421399090

Production Capacity

100sets/Month

Product Description

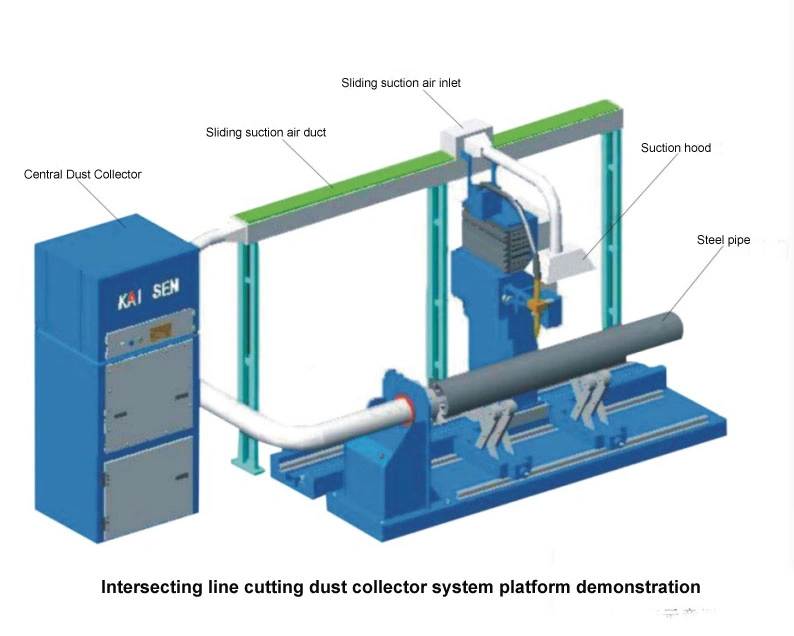

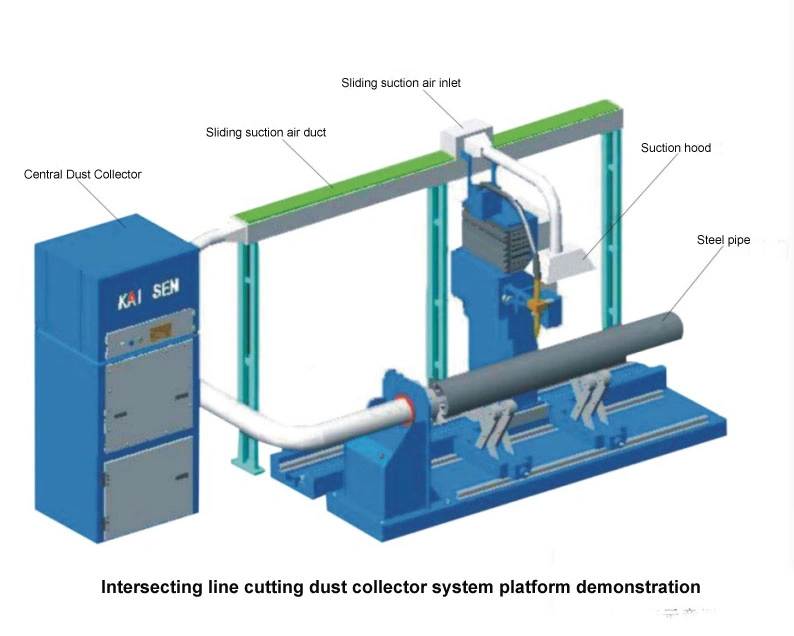

Industrial workshop fume extractor system for plasma cutting machine

Central fume extractor is a series of products developed by our company based on the requirements of different site conditions. We can design the best fume & dust capturing device and piping system according to different site conditions, and choose suitable purification system according to air flow.

Design fume & dust capturing device according to the welded particle's size, shape, welding position, welding craft, fume properties, site environment. We can provide various suction arms,fume suction nozzle, suction welding caps, suction welding torch etc.for common production. Welding rooms of different size and shape,manual / pneumatic / electric hood and the other kinds of dust capture device can also be designed for special sites need.

The structure of integrated design is compact and reasonable. A complete series of models have been developed to meet the different site conditions , whatever your production line is large scale welding or grinding workshop, welding center, robot welding line, plasma & laser cutting, you will find suitable model for you.

Notice: For KSDC-A series fan motor is configured on top of the extractor, it occupies smaller space but height is relatively higher.For KSDC-B series fan motor is configured at the back of the extractor, it occupies larger space, but height is relatively lower.

equipments in the operation and show them in the display, and it has self-diagnosis function, showing abnormal

and error conditions in the operation of the equipment automatically.The central dust & fume purification system's

performance is controlled by PLC controlling system.

2. To the position polluted by a little oil mist, the company's special spray device not only dilutes oil mist and

prevents the dust from attaching to the filter surface to reduce its service life, but also plays a role in fire

prevention.

Technical parameters

Exhibition

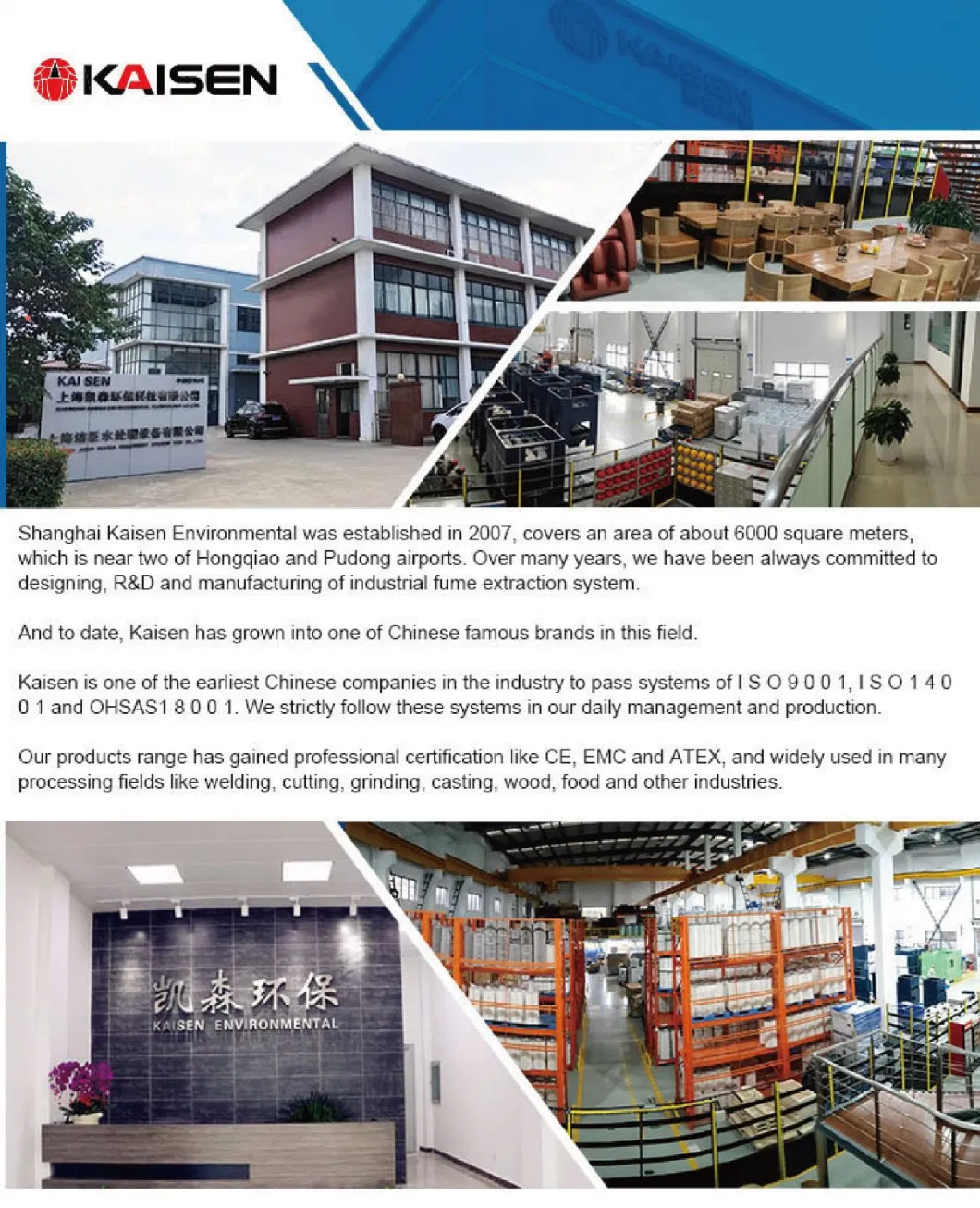

Company profile

Central fume extractor is a series of products developed by our company based on the requirements of different site conditions. We can design the best fume & dust capturing device and piping system according to different site conditions, and choose suitable purification system according to air flow.

Design fume & dust capturing device according to the welded particle's size, shape, welding position, welding craft, fume properties, site environment. We can provide various suction arms,fume suction nozzle, suction welding caps, suction welding torch etc.for common production. Welding rooms of different size and shape,manual / pneumatic / electric hood and the other kinds of dust capture device can also be designed for special sites need.

The structure of integrated design is compact and reasonable. A complete series of models have been developed to meet the different site conditions , whatever your production line is large scale welding or grinding workshop, welding center, robot welding line, plasma & laser cutting, you will find suitable model for you.

Notice: For KSDC-A series fan motor is configured on top of the extractor, it occupies smaller space but height is relatively higher.For KSDC-B series fan motor is configured at the back of the extractor, it occupies larger space, but height is relatively lower.

Main feature

1. Central Control system implements real-time monitoring and analysis on a number of important parameter ofequipments in the operation and show them in the display, and it has self-diagnosis function, showing abnormal

and error conditions in the operation of the equipment automatically.The central dust & fume purification system's

performance is controlled by PLC controlling system.

2. To the position polluted by a little oil mist, the company's special spray device not only dilutes oil mist and

prevents the dust from attaching to the filter surface to reduce its service life, but also plays a role in fire

prevention.

Technical parameters

| No | Item | Parameter |

| 1 | Model | KSDC-8609B |

| 2 | Treatment Of Air Flow | 6500m3/h |

| 3 | Motor Power | 7.5kw |

| 4 | Power Supply | 380V/50Hz or 460V/60Hz |

| 5 | Filtration Area | 135m² |

| 6 | Number Of Filter Cartridges | 9pieces |

| 7 | Filter Medium | Polyester +PTFE |

| 8 | Filtering Efficiency | >99.9% |

| 9 | Filtering Precison | ≥0.1um |

| 10 | Cleaning Way | Atomatic Cleaning |

| 11 | Compressed Air | 0.5~0.6 MPa |

| 12 | Noise | ≤75±5dB(A) |

| 13 | Weight | 1420±20KGS |

| 14 | Dimensions(excluding suction arm) | 1800×2000×2500mm |

Exhibition

Company profile