Basic Info.

Model NO.

CACW-20

Condition

New

Certification

ISO, CE, CCC

Flow Rate

3m3/H to 500m3/H

Purity

90% to 99%

Service Life

Over 10 Years

Warranty

12-18 Months

Transport Package

Wooden Case

Specification

CACW-20

Trademark

Cape-Golden

Origin

China

HS Code

8419601900

Production Capacity

100

Product Description

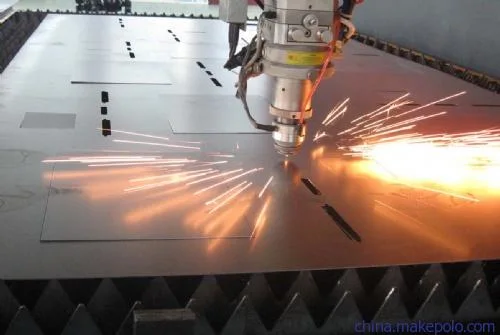

Industrial Oxygen Generator System for Cutting and Welding

A full Industrial Oxygen Generator System installation requires air compressor, refrigerated air dryer, filters, air tank, oxygen generator and gas buffer tanks.

We supply full installations but each component, and other optional supply like boosters, high pressure compressors, oxygen cylinders or filling stations can also be bought separately.

Oxygen Generator for Cutting & Welding Application

Oxygen is mainly used for metal cutting and welding. Oxygen can be oxidant of acetylene to produce high- temperature flame, to make fusion of metals. Hydrogen - oxygen flame and oxygen - acetylene flame are used for cutting and welding plates and vessels in machinery factories. Oxygen - propane flame cutting can improve the degree of cut surface finish, to replace of casting, forging, milling and creating of partial parts. Using argon as a protective gas based on its inert character for arc welding, can prevent the titanium, molybdenum, alloy and stainless steel from being oxidized and nitrided by air.

Convenience of On-site Oxygen Generator

Our PSA Industrial Oxygen Generator System reduces operator intervention and the high-labor cost, systems operate entirely automatically, in direct response to demand in the downstream distribution system. No more worries about downtime created by late deliveries, weather related influences, unexpected empties and loss of expensive cylinders. Elimination of supplier dependence is a key to greater control and efficiency. In fact, multi-level sayings are realized as oxygen gas costs are paid via your electrical bill, thereby eliminating bookkeeping, purchasing, inventory record keeping, contract negotiation and other management involvement altogether. This convenience really saves money at bottom line.

Q & A for PSA Oxygen Generator

| 1 | Q: How does Cape-Golden ensures its product quality? |

| A: Cape-Golden quality management system is strictly executed. The feedback system enables Cape-Golden to improve its product quality and to prove and compare its parts suppliers to ensure every part of the products is of good quality. Experienced and well-educated workers incarnate the perfect manufacturing techniques to Cape-Golden Industrial Oxygen Generator System machines. | |

| 2 | Q: Which features do Cape-Golden products have? |

| A: Cape-Golden air separation solutions are more reliable, more economical and more convenient. We choose qualified and time proven suppliers instead of manufacturing the parts by ourselves. The main parts Cape-Golden Industrial Oxygen Generator System are made by world famous molecular sieve manufacturers. The pneumatic control valve can operate more than 2 million times without leakage, which means more than 7 years continuous operation. The SMC brand solenoid valve has a working life of hundreds of million times. The control system incorporates SIEMENS PLC and controls the system precisely. | |

| 3 | Q: Does operation to the oxygen generator need attention? |

| A: The Industrial Oxygen Generator System is PLC automatically controlled and needs no attention during operation. Remote control can be realized. Control to peripheral equipment including air compressor and refrigerant dryer can be integrated to enable one switch operating the whole system. Optional Cape-Golden intelligent monitor and control system enables flow, purity and pressure online display. It reminds the operator to do routine maintenance to the system and indicates trouble-shootings. And the whole system can be operated by single touch. |