Basic Info.

Model NO.

FR-270

Nominal Force

1000kn

Maximum Pressure

25 MPa

Maximum Opening Distance of Slider

1000 mm

Type

Gantry Hydraulic Press

Certification

ISO9001

Transport Package

Plywood Case

Trademark

ubright

Origin

Cn

Product Description

Product display

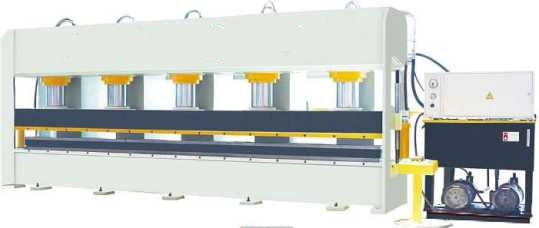

Product display Frame Type Hydraulic Pres

Application: The frame type hydraulic press is also called gantry hydraulic press. The machine adopts the steel structure of gantry frame, and the mechanical deformation is small after vibration aging treatment. The frame design is designed by finite element method, with high rigidity and high precision. Gantry type hydraulic press table can move up and down, greatly expanding the opening and closing height of the machine, more convenient to use. The frame hydraulic press is composed of main cylinder, hydraulic power system and electrical system. The worktable is welded with high-quality steel plate to ensure reliability and durability. It is widely used in disassembly, forming, correction, straightening, press fitting and sheet metal forming in the mechanical industry. It can be used as a necessary pressure equipment in the modern automobile repair industry.

Application: The frame type hydraulic press is also called gantry hydraulic press. The machine adopts the steel structure of gantry frame, and the mechanical deformation is small after vibration aging treatment. The frame design is designed by finite element method, with high rigidity and high precision. Gantry type hydraulic press table can move up and down, greatly expanding the opening and closing height of the machine, more convenient to use. The frame hydraulic press is composed of main cylinder, hydraulic power system and electrical system. The worktable is welded with high-quality steel plate to ensure reliability and durability. It is widely used in disassembly, forming, correction, straightening, press fitting and sheet metal forming in the mechanical industry. It can be used as a necessary pressure equipment in the modern automobile repair industry. Machine Feature:

Machine Feature: 1.The fuselage adopts computer optimization design, and the frame structure of all steel plate welding has good accuracy retention.

2.Hydraulic control adopts cartridge valve integrated system, which is reliable, large flow and long service life. The system is highly integrated, reducing the connection pipeline and leakage point.

3.It adopts button centralized control, and has three operation modes of manual adjustment and semi-automatic adjustment (fixed range single time and fixed pressure single time).

4.The frame type adopts four corners and eight faces guide rail, which has high guiding precision. Strong resistance to eccentric load and centralized lubrication.

5.The sliding block has fast movement speed and high working efficiency.

6.The working pressure of slide block, the travel range of no-load fast downward and slow forward can be adjusted according to the process requirements.

Product Paramenters

| Item | Unit | 100T | 120T | 160T | 200T | Hub Model |

| Nominal force | KN | 1000 | 1200 | 1600 | 2000 | 8-15 |

| Maximum pressure | Mpa | 25 | 25 | 25 | 25 | 8-15 |

| Maximum opening distance of slider | mm | 1100 | 1100 | 1200 | 1200 | 8-20 |

| Effective stroke of slider | mm | 500 | 500 | 600 | 600 | 8-24 |

| Effective area of worktable | mm | 1000*800 | 1000*800 | 1400*800 | 1400*800 | 8-25 |