- Overview

- Product Description

- Product Parameters

- Product advantage

- Details

- Sample

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

HGTECH CNC Stainless Steel Aluminium Sheet Metal Fiber Laser Cutting Machine

(Model:GF3015)

HGLaser, professional Metal Cutting Machine manufacturers, with advanced metal laser cutting machine equipment, first-class technology, quality service, get good reputation in fiber laser cutting machine equipment industry.

| Machine Model | GF3015 | GF4020 | GF6020 | |

Cutting Area (LXW) | 3000mmX1500mm | 4000mmX2000mm | 6000mmX2000mm | |

| Laser Source | HGTECH-Raycus | HGTECH-Raycus | HGTECH-Raycus | |

| Laser Type & Powert | Fiber & 1000/1500/2000/3000 | Fiber & 1000/1500/2000/3000 | Fiber & 1000/1500/2000/3000 | |

| Laser Wavelength | 1070nm±10nm | 1070nm±10nm | 1070nm±10nm | |

| CNC System | CYPCUT | CYPCUT | CYPCUT | |

| Servo Motor | YASKAWA (Japan) | YASKAWA (Japan) | YASKAWA (Japan) | |

| Laser Cutting Head | Raytools | Raytools | Raytools | |

| Display | 19'Industry LCD | 19'Industry LCD | 19'Industry LCD | |

| Max Moving Speed | 80m/min,Acceleration is 0.8G | 80m/min,Acceleration is 0.8G | 80m/min,Acceleration is 0.8G | |

| Position Accuracy ( X and Y axis) | ±0.05mm | ±0.05mm | ±0.05mm | |

| Reposition Accuracy ( X and Y axis) | ±0.03mm | ±0.03mm | ±0.03mm | |

| Stroke | X-axis | 1530mm | 2030mm | 2030mm |

| Y-axis | 3050mm | 4050mm | 6050mm | |

| Z-axis | 100mm | 100mm | 100mm | |

| Motion | X and Y axis | Rack & Pinion | Rack & Pinion | Rack & Pinion |

| Structure | Z-axis | Ball Screw | Ball Screw | Ball Screw |

| Power Supplier Requirement | 380V 50/60Hz 50A | 380V 50/60Hz 50A | 380V 50/60Hz 50A | |

| Max Loading (KG) | 600KG | 1300KG | 1900KG | |

| Machine Weight | ≤4000kg | ≤5000kg | ≤6000kg | |

| Appearance Size | 4250mmX2430mmX1800mm | 5555mmX3050mmX1800mm | 7850mmX3050mmX1800mm | |

* High cutting speed: 2-3 times faster than YAG or Co2 laser

* Long lifetime span: laser source lifetime over 10 years with stable performance.

* High cutting accuracy: Finest laser beam up to 0.01mm

* Low maintenance: Almost totally free of Maintenance

* Most advance cutting machine on the world

1.The fiber laser cutting mchine's controller with a touch screen operating system:

Fiber laser controller installed on the computer.

Ytterbium laser cutting system, automatic optimized cutting path calculation, industrial computer installed software;

Touch screen operation system to control the laser head (adjust the distance between the laser head and metal material); wireless control handle can control the laser cutting head movement trajectory.

2.The fiber laser cutting mchine is adopts Lasermach(USA) and PRECITEC(Germany ) automatic focus laser cutting head (metal sensor) :

Laser cutting head nozzle contact metal plate surface, cutting head automatically move up and down, high sensitivity, good stability. No obvious spark phenomenon.

3.The metal laser cutter with 3HP high-power water chillers:

adopts water cooling method to keep the laser head always work in constant temperature(plus or minus 5 degrees), to ensure the the stability and fast operation of the laser.

photoelectric conversion rate is high, high beam quality, work life of more than 100,000 hours, no maintenance costs.

5.Universal ball screw and jagged shaped working platform

loading metal material fast and keeping stable feeding work. jagged platform fixing strip can fix material to reduce the spark splash when cutting.

6.The fiber laser cutting machine is adopted Japan's Panasonic servo motor and drive:

improve the cutting speed and stability. Positioning accuracy: ≤ ± 0.05mm; maximum moving speed 90m / min, maximum effective cutting area 1500 * 3000mm. The servo system has excellent dynamic response acceleration characteristics for smooth operation, reliable, no maintenance.

7.Self-service refueling, alarm system, smoke device:

Laser cutting machine tracks can automatically be refueled, always ensure track lubrication. laser cutting machine alarm system to remind the situation of the role of the machine. Smoke device can extract the smoke in the cutting process, to protect the working environment.

8.Rotary aids:

the unique design with rotary auxiliaries can solve the technical problems for cutting pipe.

Materials and Main Application Industry

The Optic Fiber Laser Cutting Machine Main Processing Materials

stainless steel, carbon steel, manganese steel, galvanized sheet, all kinds of alloy plate and rare metals.

The Optic Fiber Laser Cutting Machine Main Application Industry

sheet metal industry, kitchenware industry, elevator mobile phone industry, advertising industry, chassis cabinet industry, machinery parts processing industry, precision machining industry, automobile manufacturing industry, daily light industry, agricultural machineryand food machinery industry, hardware bathroom industry, Medical fitness equipment industry.

2). Providing professional service to customers, any call for technical help will be solved in 24 hours

3). Free training, free maintenance and free technical support within warranty period

4). We supply life-long free service in technical upgrading.

About Us

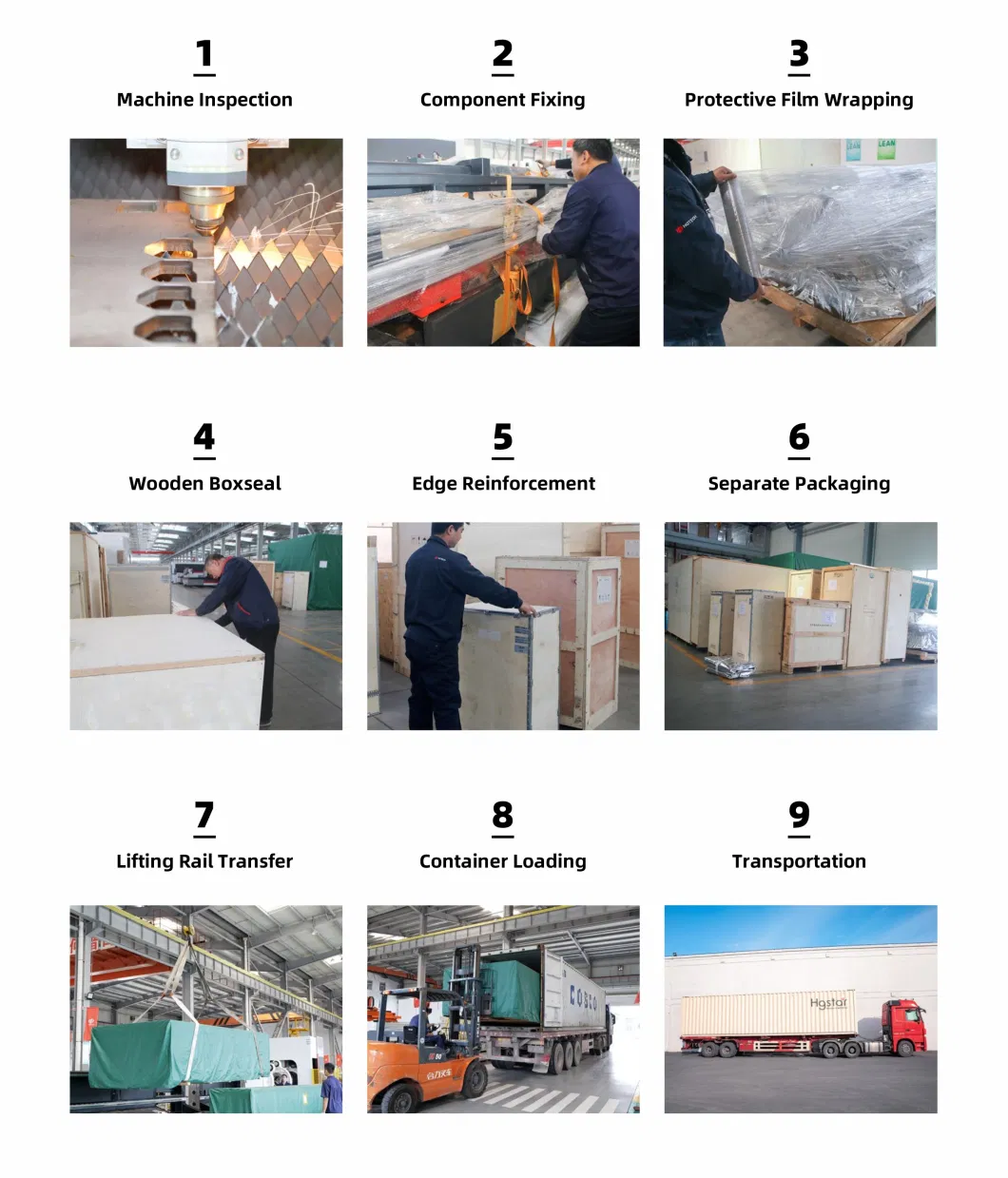

Q: What's the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact -China HGLaser!

1. The exact material you want to cut? (Stainless steel, carbon steel, mild steel, etc.)

2. The cutting depth on above materials?(max thickness, 3 mm, 5 mm, 7 mm, 15 mm....)

3. The working area you demand? (max dimension of material,width*length, 1500*3000 mm,...)

Need more information please feel free to contact us-HGLaser!---Right Now!!