- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Company Profile

- Customer Visit

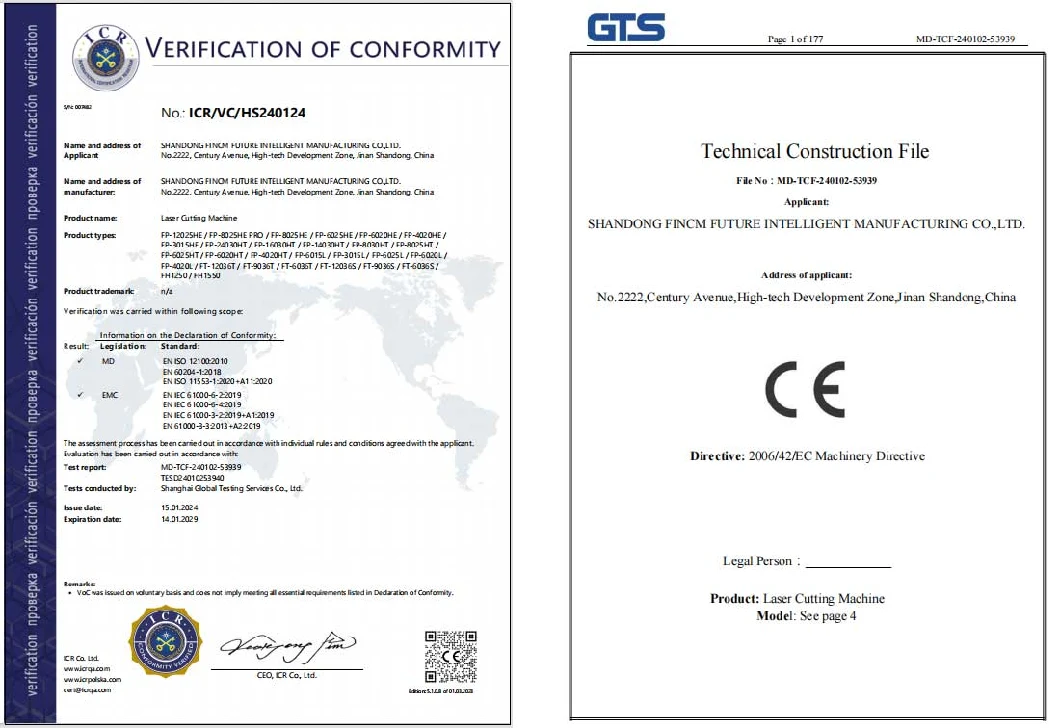

- Certifications

- FAQ

Basic Info.

Product Description

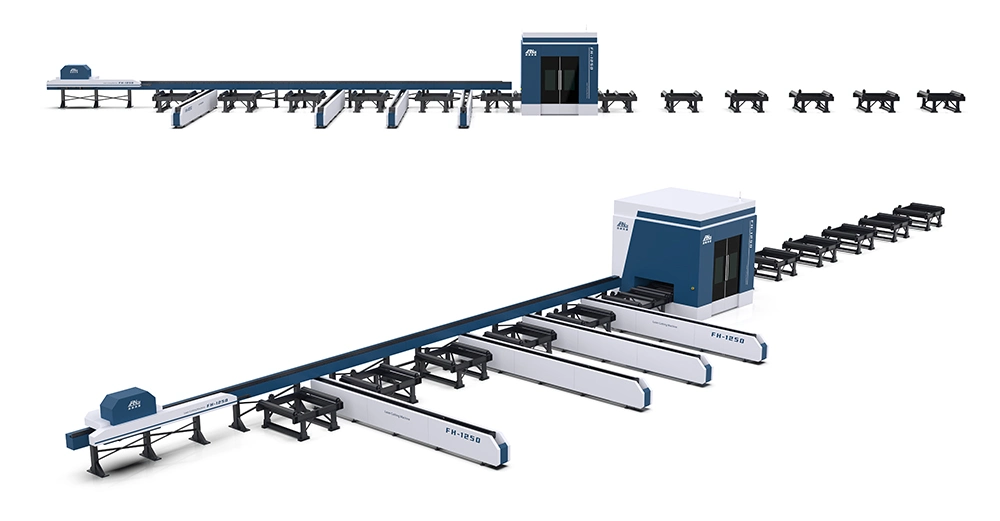

H-beam Laser Cutting Machine FH-1250

The machine can instead of beam cutting, beveling, coping, drilling, marking machines in one,highly improved steel beams processing efficiency.

Introduction

1. Dedicated to laser cutting of cross-section cutting shapes such as H-beam steel/channel steel, etc.

axis linkage cutting control system can directly generate G code, three-dimensional simulation operation, node

expansion, ultra-long type separation, material optimization, etc.; It is suitable for the three-dimensional cutting of

various types of steel, angle steel, I-beam steel, and flat steel). Support TEKLA steel structure deepening software

three-dimensional modeling data file cutting. Support AUTOCAD three-dimensional modeling file program compilation.

Model | HF-1250 |

| Wing Width | 100-600mm |

| Web width | 100-1250mm |

| Cutting Thickness | ≤30mm |

| Maximum Weight of Single Steel | 6000kg |

| Cutting Method | Laser |

| Positioning Accuracy | ±0.05mm |

| Swing Cutting | A axis: ±90°C axis: ±90° U axis: Follow-up Acceleration: 0.5G |

Processing Content | Cutting off/Perforation/Lettering/Marking |

| Laser Cutting Head Brand | OSPRI/BOCI (Customized) |

| Laser Power Brand | MAX/RAYCUS (Customized) |

| Control System | WisCut |

coordinate movement, high production efficiency,

multi-machine interconnection, unified code, batch cutting

cutting,multi-option track opening sorting, automatic

simultaneous discharge of multiple parts, material

saving priority, efficient and convenient

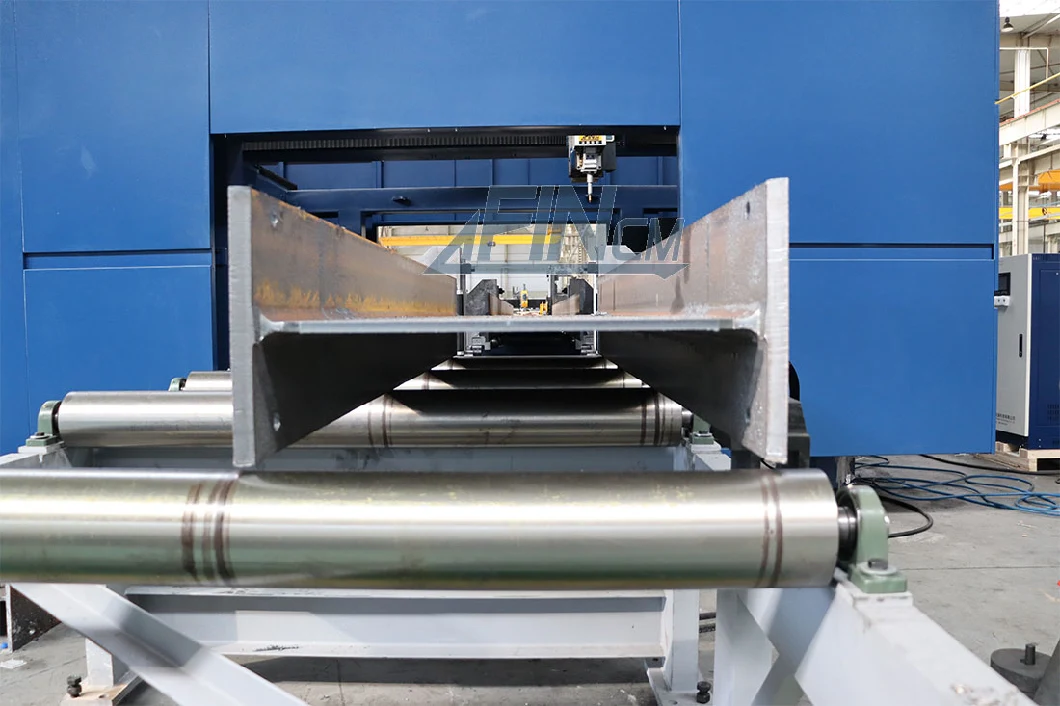

Three-dimensional six-axis CNC system,Cutting

off/Perforation/Lettering/Marking,Integrated system

Equipped with a comprehensive database of cutting

process parameters, the cutting process is adjusted in

real time to ensure the cutting quality

More Details

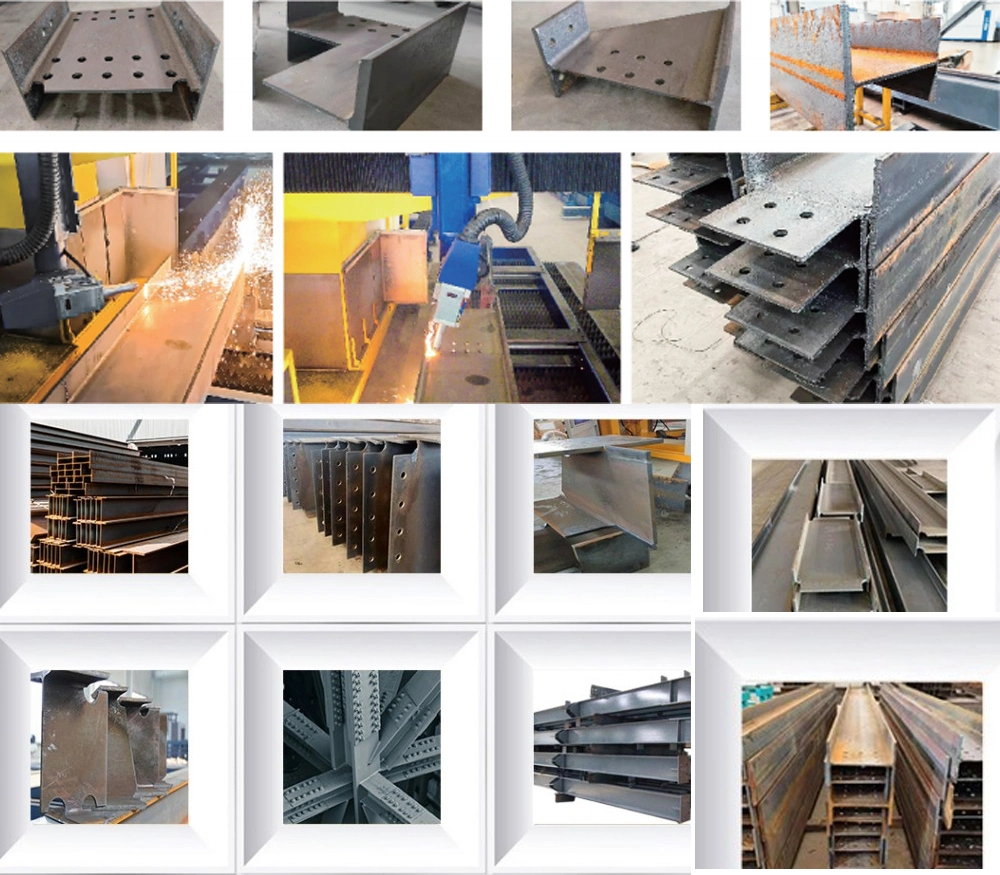

Cutting Samples

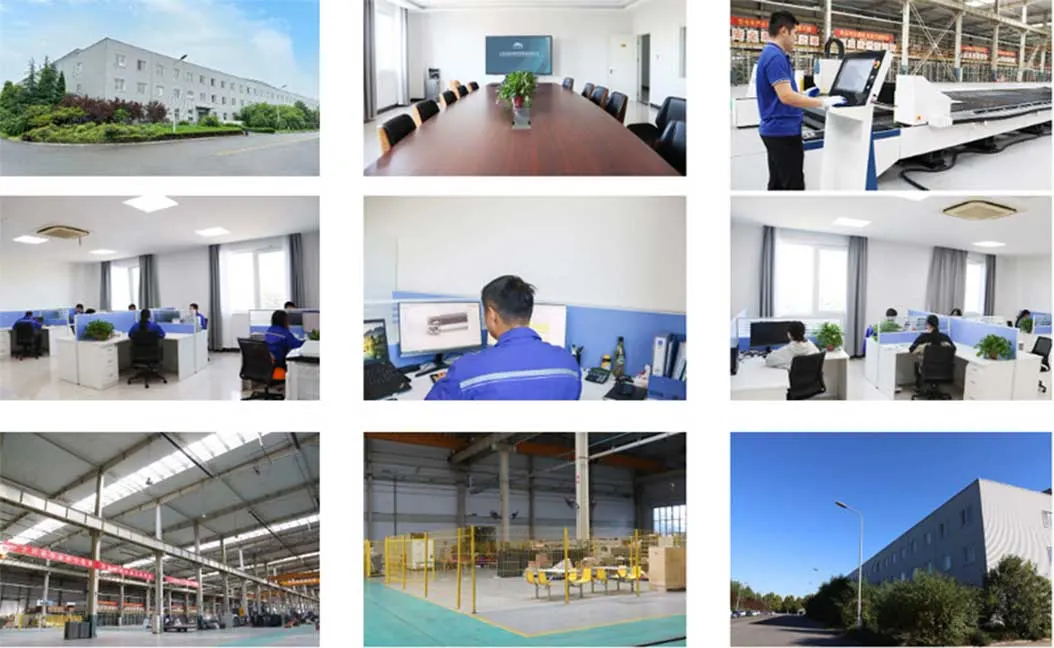

Shandong FINCM Future Intelligent Manufacturing Co., Ltd. is an intelligent technology company integrating intelligent manufacturing equipment, automated production lines, laser processing applications, and services. The factory is located in Jinan, Shandong.

Laser processing application products, as one of the company's main research and development directions, are committed to realizing the cutting, welding, and cladding of metal materials such as profiles, plates, and pipes, and the cutting and engraving of non-metallic materials in many fields and full coverage applications.

1. Can you tell me the actual address of the company and whether I can visit the factory?

A: Our factory is located in No. 2222, Century Avenue, High-tech Zone, Jinan City, Shandong Province. Warmly welcome to visit our factory.

2. When I got this machine, but I don't know how to use it. What should I do?

A: We will send a video and English manual with the machine firstly. If you still have some doubts, we can talk by telephone or Skype and video connection. Moreover, our after-sales staff will go to your company to assist in the installation and commissioning of equipment if you need it.

3. If some problems happen to this machine during the warranty period, what should I do?

A: We will supply free parts during the machine warranty period if the machine has some problems. We also supply free life-long after-sales service. So any doubts, just let us know and we will give you solutions.