Basic Info.

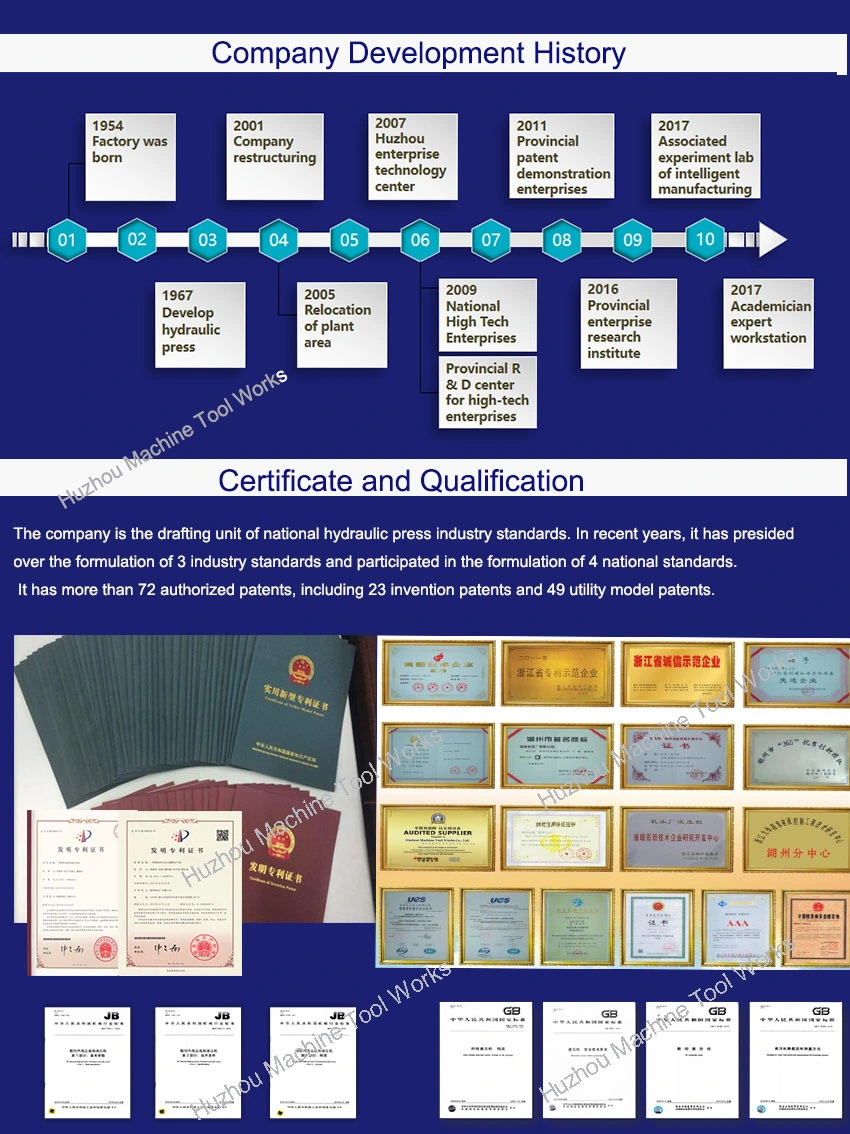

Certification

ISO9001, CE

Transport Package

Wood Package

Trademark

HJC

Origin

Huzhou, China

HS Code

8462919000

Production Capacity

1 Set/ Two Month

Product Description

ISO9001 and CE certificate servo motor control forging hydraulic press

Machine Introduction:

This series of hydraulic presses is mainly used for metal hot forging forming and has all the functions required for die forging.

This equipment adopts a frame structure, and the guide rail adopts an adjustable diagonal wedge type four corner and eight sided flat guide rail. It has advantages such as high guiding accuracy and good accuracy retention. The equipment is equipped with an independent hydraulic station and electric control cabinet, which can achieve inching, manual, and semi-automatic operation of the hydraulic machine.

The working pressure and stroke size of this series of hydraulic presses can be adjusted within the specified range according to process requirements. The hydraulic press operates stably and has high production efficiency, making it an indispensable specialized equipment for using die forging technology.

Nominal force: 5000KN-150000KN

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your purpose ,you can also send us the products drawing ,we will choose the most suitable machines or customized machines for you .

2: How can I get a quotation?

A: Pls tell us the machine you need, including quantity, raw materials and other requirements.

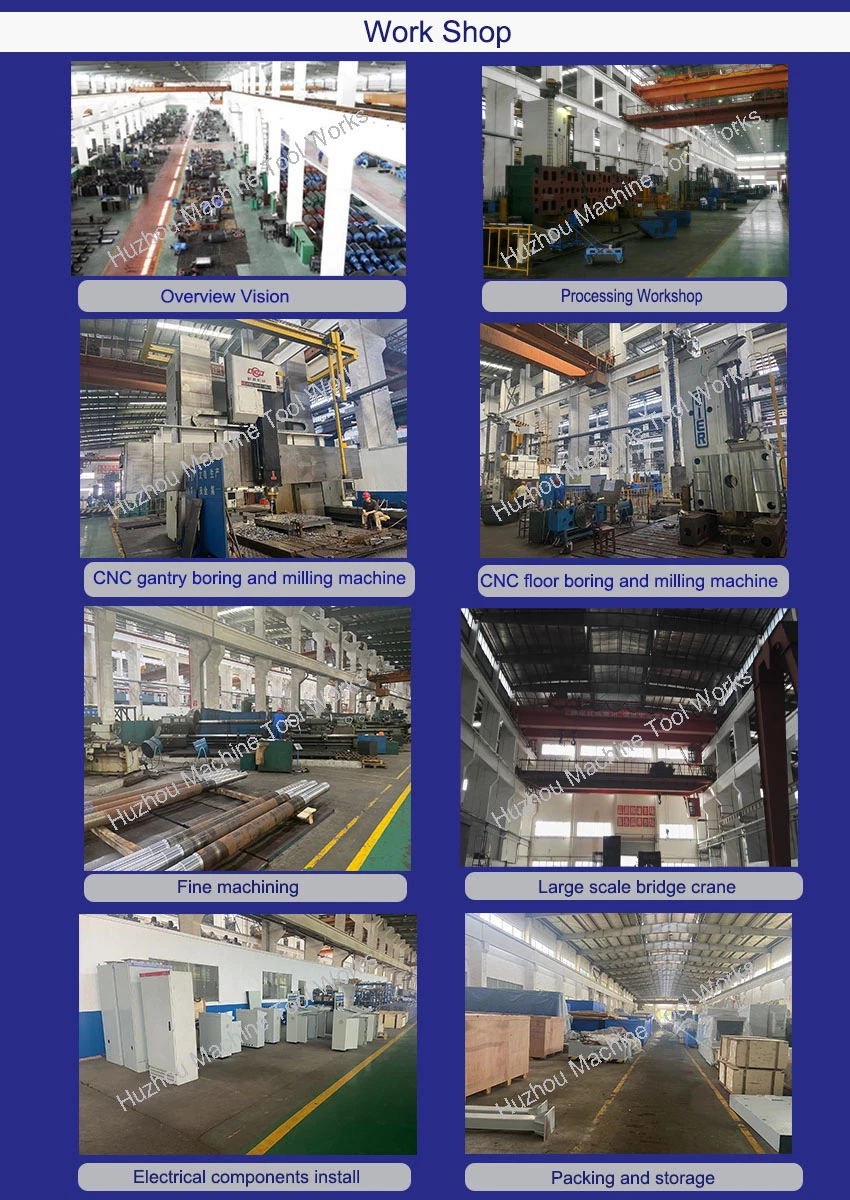

3: Where is your factory located? How can I visit there?

A : Our factory is located in Huzhou City ,Zhejiang Province, China, which near the Shanghai airport.

You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, C/L and CIF all acceptable.

5:How can i trust your company?

A:We have professional design, we can provide you suitable suggestion and lowest price.

Assessed by third party, national patents and CE, ISO for all equipment.

Machine Introduction:

This series of hydraulic presses is mainly used for metal hot forging forming and has all the functions required for die forging.

This equipment adopts a frame structure, and the guide rail adopts an adjustable diagonal wedge type four corner and eight sided flat guide rail. It has advantages such as high guiding accuracy and good accuracy retention. The equipment is equipped with an independent hydraulic station and electric control cabinet, which can achieve inching, manual, and semi-automatic operation of the hydraulic machine.

The working pressure and stroke size of this series of hydraulic presses can be adjusted within the specified range according to process requirements. The hydraulic press operates stably and has high production efficiency, making it an indispensable specialized equipment for using die forging technology.

Nominal force: 5000KN-150000KN

| No. | Item | Unit | Specification | |||||||||||

| 1 | main cylinder nominal force | KN | 3150 | 5000 | 8000 | 12500 | 16000 | 25000 | 30000 | 40000 | 50000 | 60000 | 70000 | |

| 2 | Horizontal cylinder pressing force | KN | 1000×2 | 3150×2 | 5000×2 | 8000×2 | 10000×2 | 15000×2 | 18000×2 | 25000×2 | 30000×2 | 36000×2 | 40000×2 | |

| 3 | Daylight | mm | 1100 | 1500 | 1500 | 1600 | 2000 | 2200 | 2200 | 2800 | 3000 | 3500 | 3500 | |

| 4 | Main cylinder stroke | mm | 700 | 900 | 800 | 800 | 800 | 1000 | 1000 | 1200 | 1500 | 1800 | 1000 | |

| 5 | Horizontal cylinder stroke | mm | 200 | 400 | 400 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 | |

| 6 | Worktable size | LR | mm | 900 | 1000 | 1000 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | 2500 | 2800 |

| FB | mm | 900 | 800 | 1000 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | 2500 | ||

| 7 | Maximum distance between the installation surfaces of the left and right pressure heads | mm | 1000 | 1200 | 1200 | 1600 | 1800 | 2000 | 2200 | 2500 | 2800 | 3000 | 3000 | |

| 8 | Horizontal cylinder middle height | mm | 200 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 750 | 900 | 1100 | |

| 9 | Main slide speed | Fast descent | mm/s | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 250 | 250 |

| work | mm/s | 30-80 | 30-80 | 30-80 | 25-70 | 25-70 | 25-70 | 25-70 | 25-70 | 25-70 | 25-70 | 20-70 | ||

| return | mm/s | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 250 | 250 | ||

| 10 | Horizontal slide speed | work | mm/s | 20-100 | 20-100 | 20-80 | 20-80 | 20-80 | 20-80 | 20-80 | 20-70 | 20-70 | 20-70 | 20-70 |

| return | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 80 | 80 | 80 | 80 | ||

| 11 | Main motor power | KW | 100 | 160 | 250 | 320 | 400 | 650 | 750 | 1000 | 1250 | 1450 | 1600 | |

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your purpose ,you can also send us the products drawing ,we will choose the most suitable machines or customized machines for you .

2: How can I get a quotation?

A: Pls tell us the machine you need, including quantity, raw materials and other requirements.

3: Where is your factory located? How can I visit there?

A : Our factory is located in Huzhou City ,Zhejiang Province, China, which near the Shanghai airport.

You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, C/L and CIF all acceptable.

5:How can i trust your company?

A:We have professional design, we can provide you suitable suggestion and lowest price.

Assessed by third party, national patents and CE, ISO for all equipment.