Basic Info.

Model NO.

WT-PC002

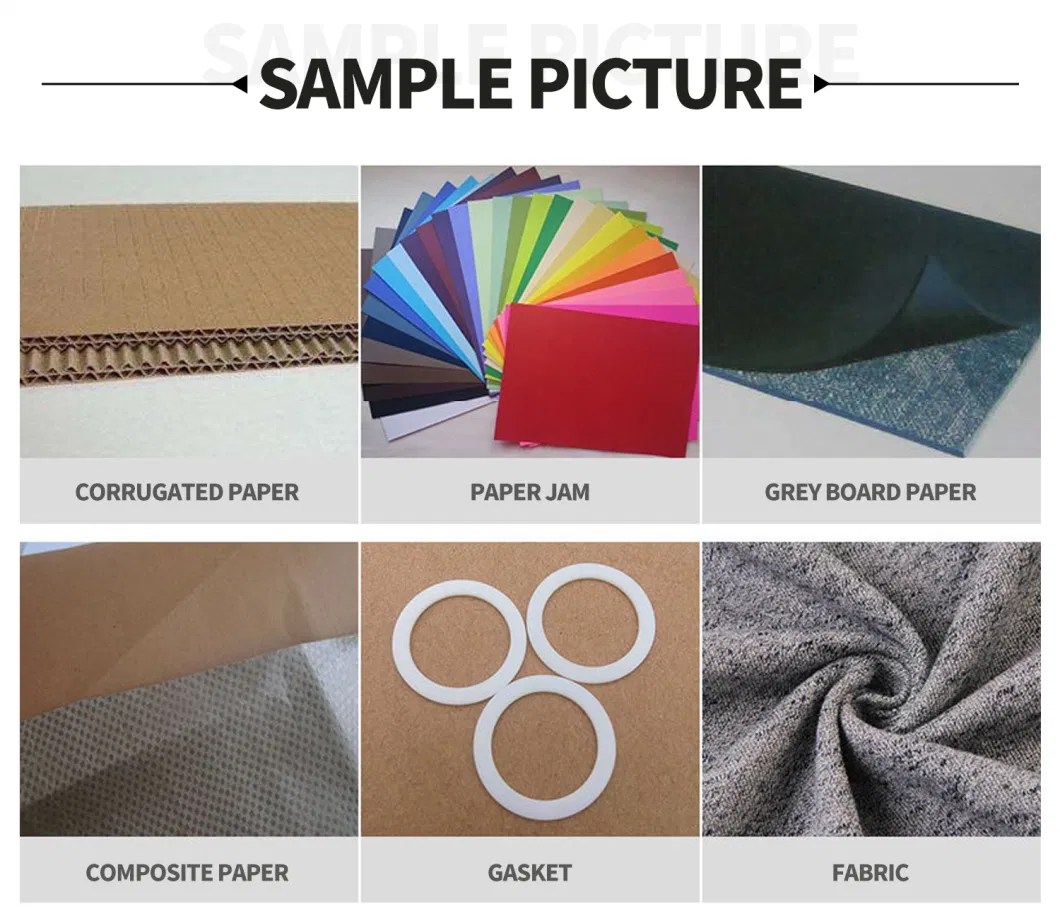

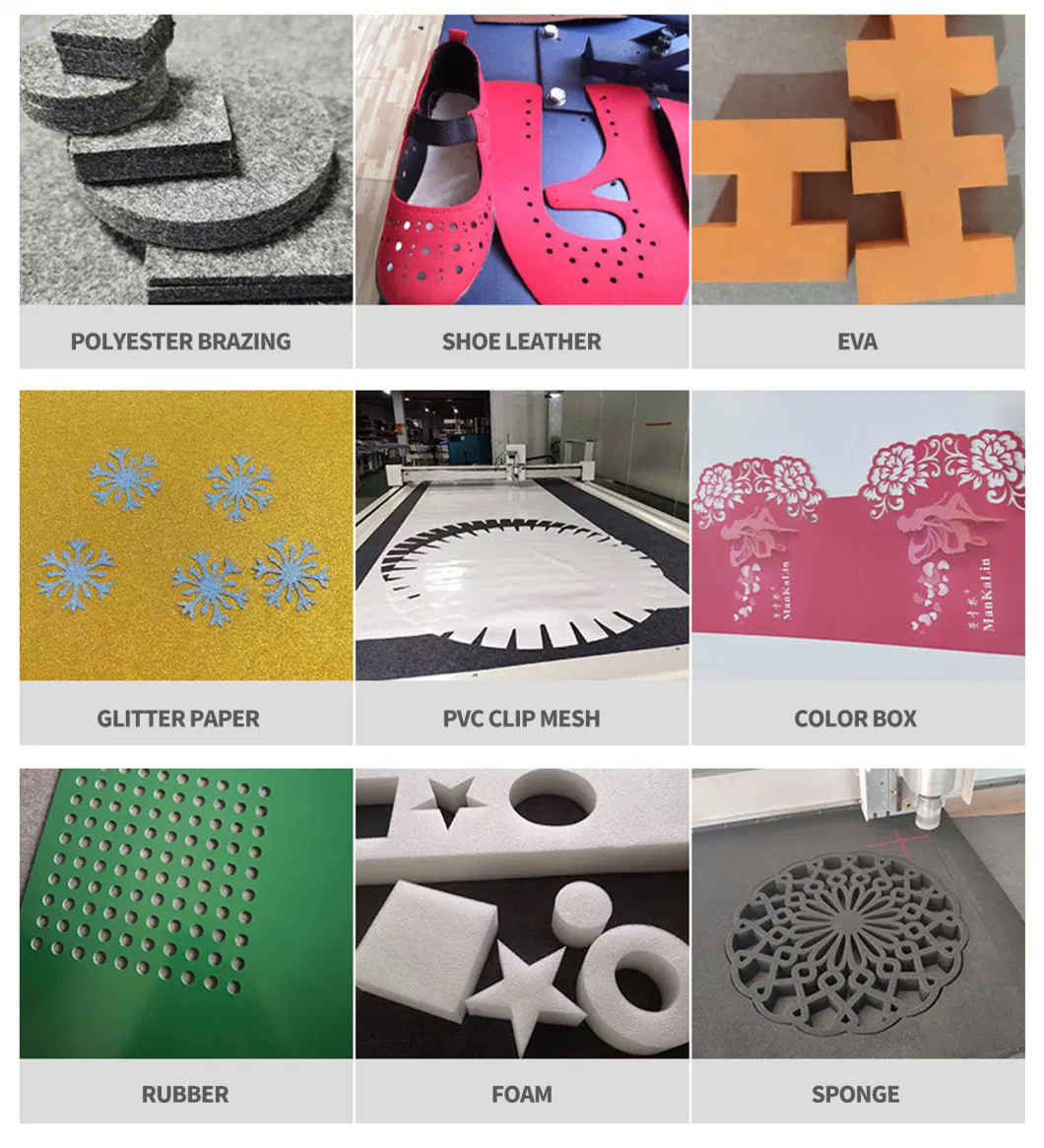

Application

Paper, Leather, Fabric

Power Source

Electric

Layout

Horizontal

Name

Carton Sample Carton Box Flatbed Cutting Machine

Cutting Materials

Cloth Fabric Garment Wool Textile Silk

Type

Paper Cutting Machine

Fixed Mode

Vacuum Suction Table

Color

White

Working Area

1600mmx2500mm

Cutting Speed

1mm/S ~ 1000mm /S

Cutting Thickness

Knife Cutting 0.1mm ~ 30mm, Crushing Thickness up

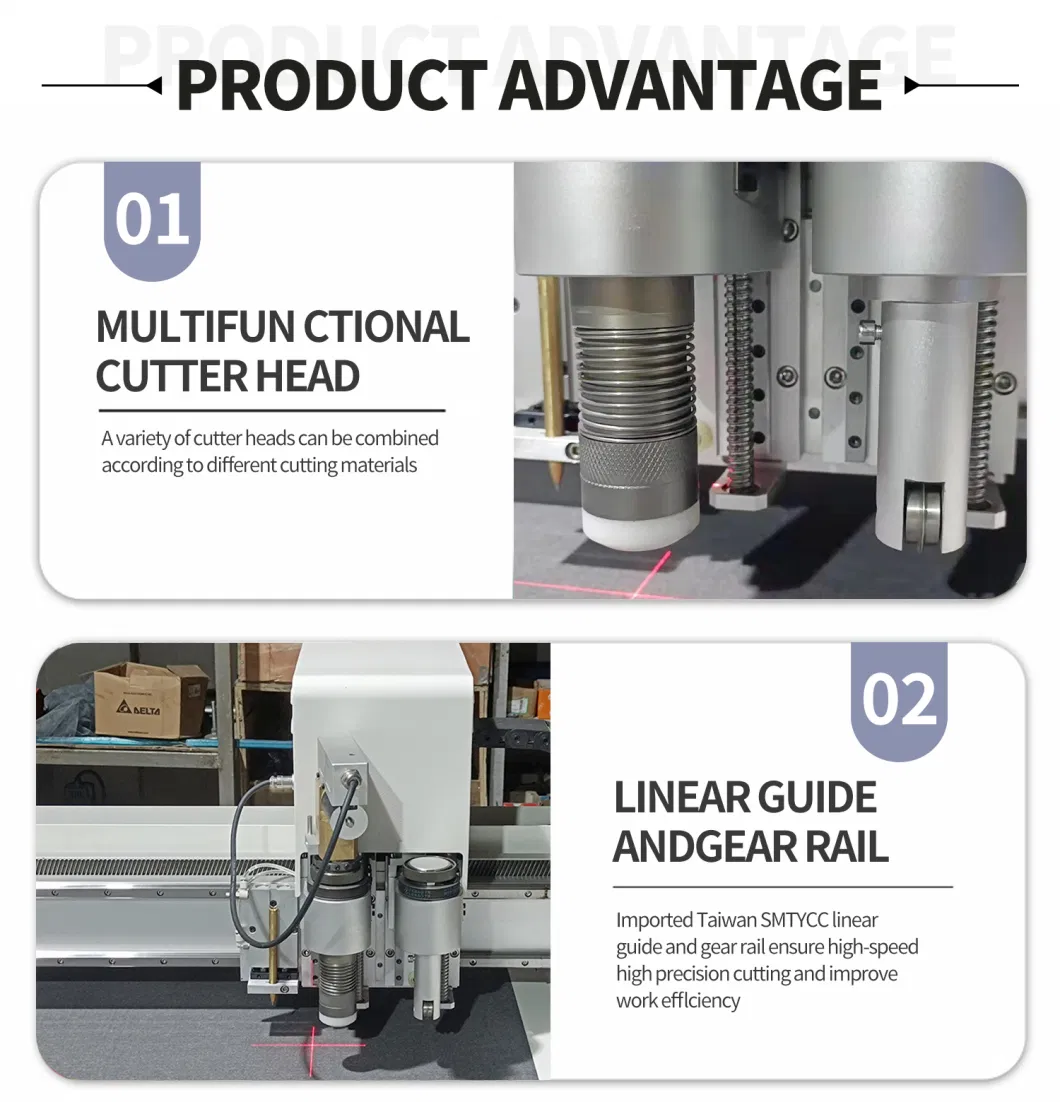

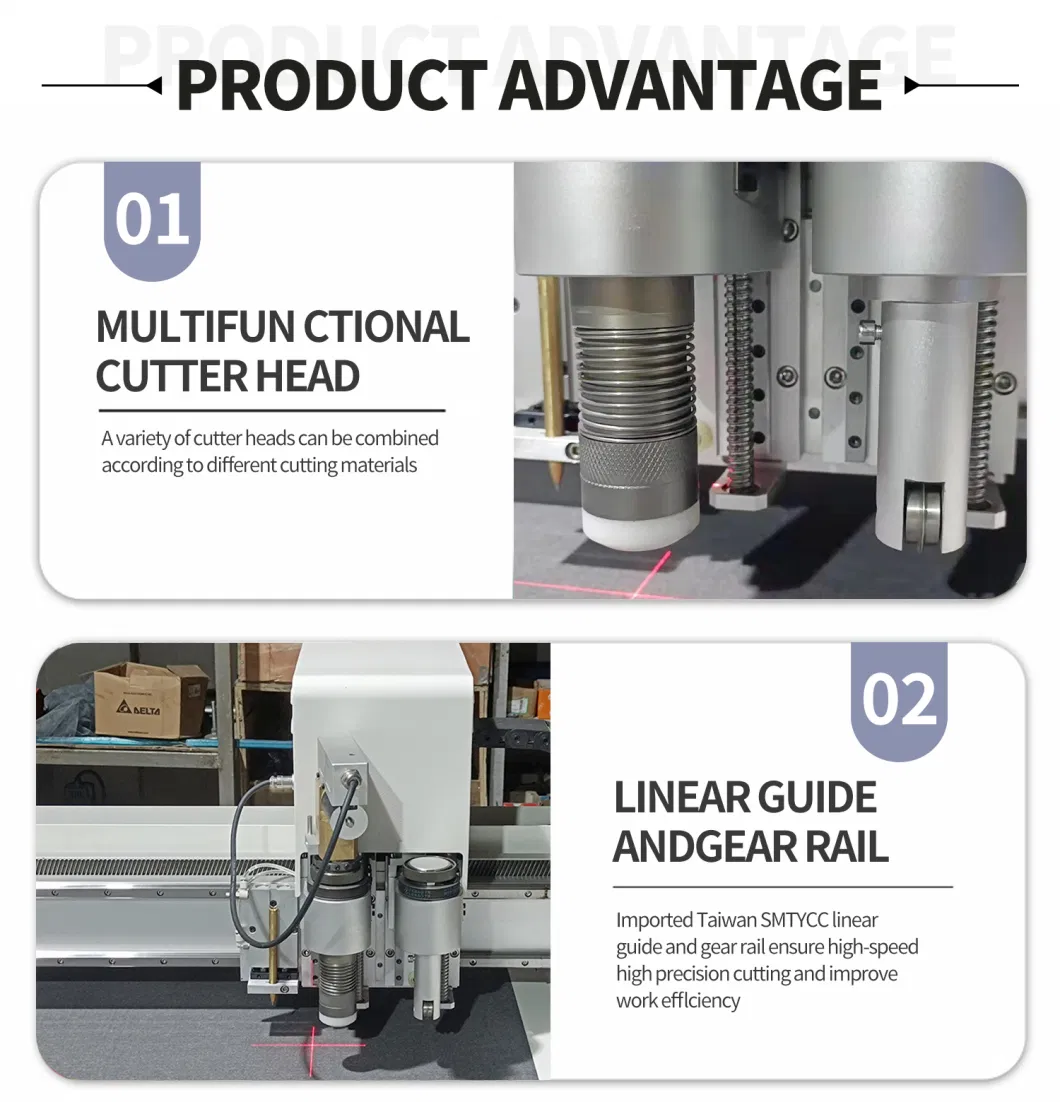

Multifunctional Head Cutting Tools

Oscillating Knife,Driven Rotary Cuttting Tool

Rated Power

11kw or Others

Transport Package

Sea-Worthy Free Fumigation Plywood

Specification

2400 x 1880 x 1300mm

Trademark

WT

Origin

Dongguan City China Prc

HS Code

84411000

Production Capacity

50 Sets/Month

Product Description

Factory Price Corrugated Box Making CNC Cutter Digital Industrial Cardboard Box Making Cutter Machine

FAQ

Q:How about the warranty time?

A:One year.But if there is any need pls be free to contact us,we will try our best to meet your needs.We always take our clients as friends and partners.

1.Multifunctional heads optonal

Vibration knife (oscillatory knife),Circular knife (round knife / rotary knife),Oblique knife (V-cut),Marking pen,Punching roller (round punching/v-punching/optional),Milling knife ,Drag knife,Penumatic knife,Projector and camera optional

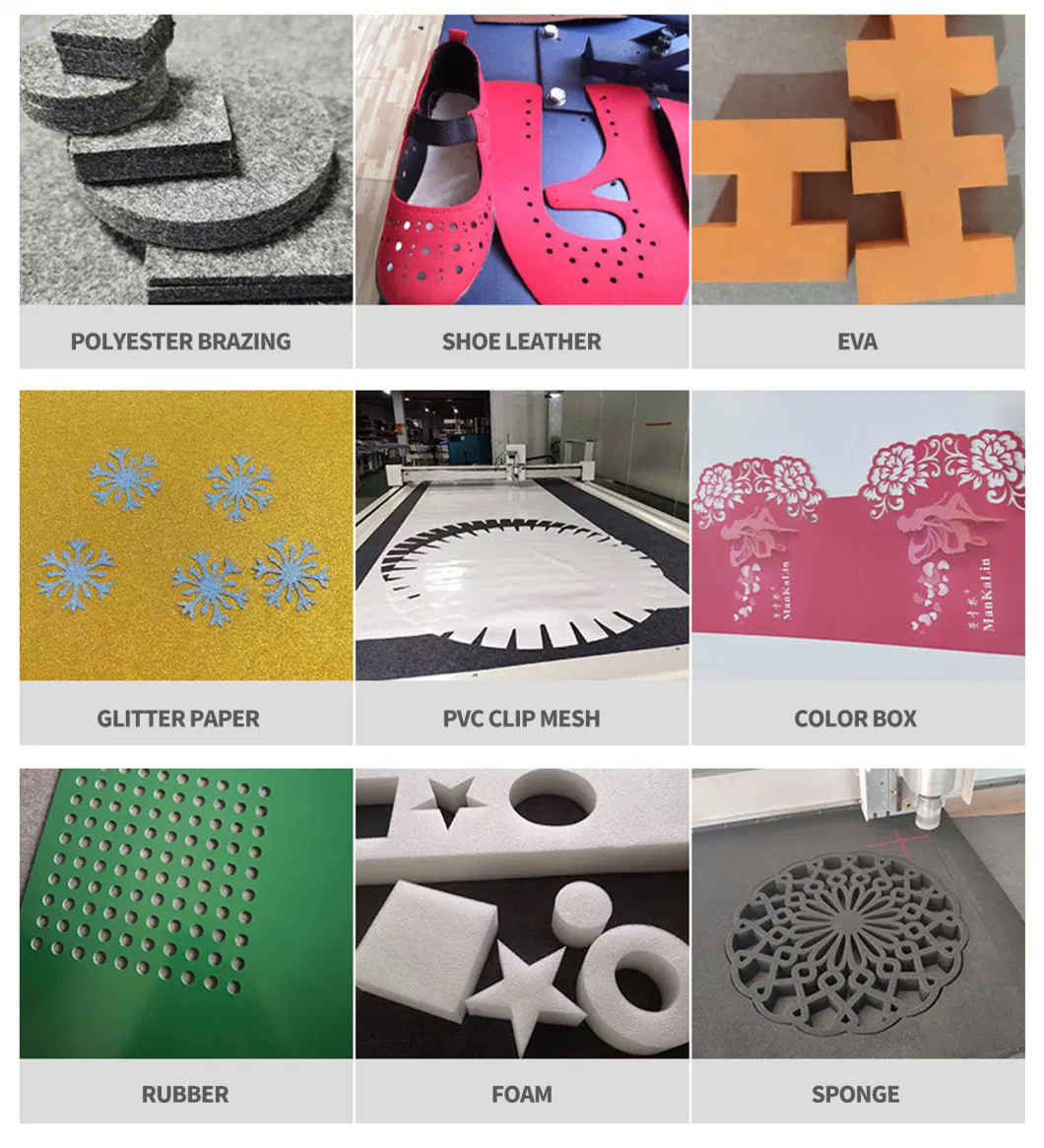

2.Cutting material

Honeycomb paperboard, corrugated paper, plastic corrugated paper, gray board paper, cardboard, stickers, film, fiber composite materials, artificial leather, cloth, PU, rubber sheet, gasket, pearl cotton, fiberboard and other materials

| Technical Parameters | |

| Model | WT-PC1625 |

| Cutting size | 1200x 1200mm |

| Dimension | 2400x 1880 x 1300mm |

| Digital Control Panel | 7"Touch display control penal |

| Cutting speed (2) | 1mm/s ~ 1000mm/s |

| Cutting thickness (2) | Knife cutting 0.1mm ~ 30mm, crushing thickness up to 15mm |

| Cutting accuracy | ±0.2mm, |

| Repeated cutting accuracy | ≤0.1 mm |

| Minimum cut circle diameter | ≥3mm(related to materials) |

| Control System | 9-axis independent motion controller (5-axis linkage) + multi-execution instant embedded control system |

| Drive System | Digital Servo |

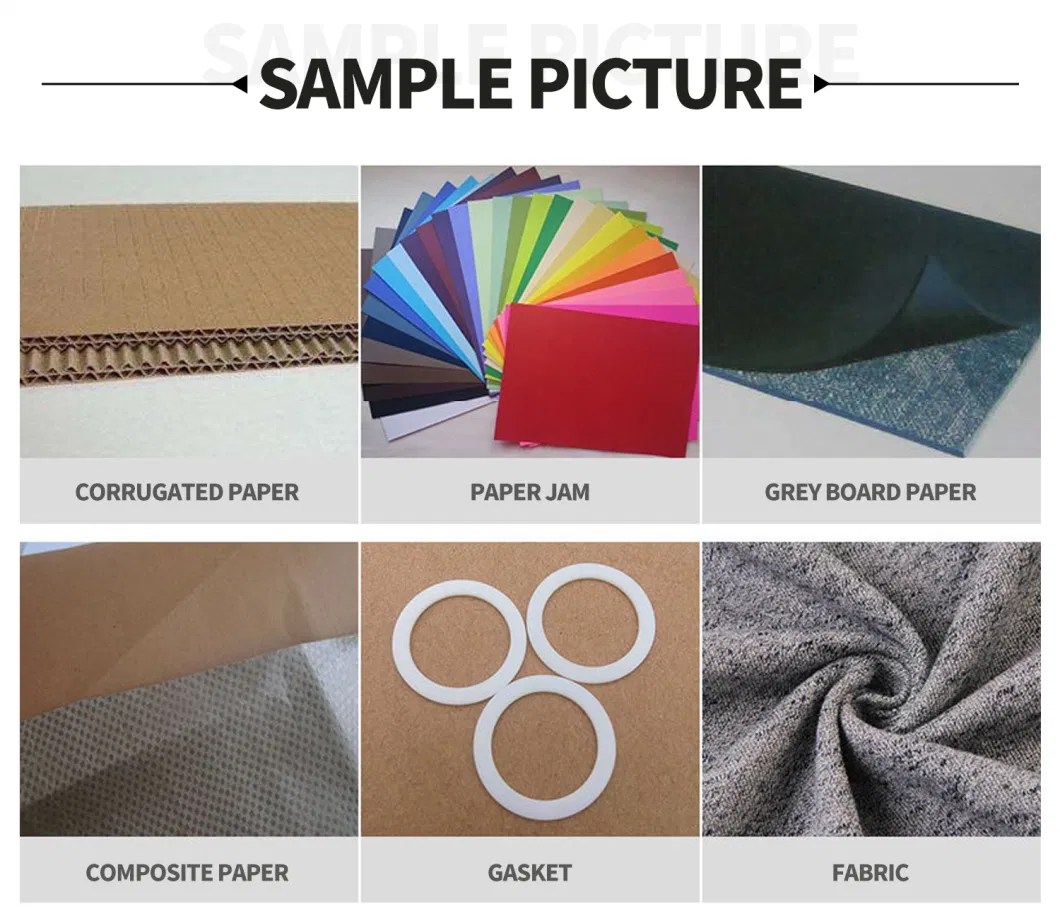

| Transmission | Taiwan YYC rack and pinion, PMI linear guide, TBI ball screw pair |

| Towline cable | IGUS, Germany |

| Pneumatic components | AIRTAC |

| Sensor component | Baumer, Swiss |

| Machine material | 43.5mm Honeycomb aluminum plate |

| Cutting table mat | 4mm High ventilated fiber mat (3) |

| Number of pens | 2 groups, crease ,Cutting knife (maximum depth can be cut 3mm) |

| Position Registration | Cross red light (optional visual positioning system) |

| Command system | HP-GL compatible format, software resolution: 0.025, 0.01, 0.1,1 |

| Transmission interface | RJ45 network port, one-to-many and many-to-one communication, the maximum transmission distance is 100 meters |

| Working voltage/ frequency | AC 220V±10% 50/60±1HzPower ; MAX_ 2.5KW (requires D-type 16A socket, GB 2.5 mm2 wire) |

FAQ

Q:How about the warranty time?

A:One year.But if there is any need pls be free to contact us,we will try our best to meet your needs.We always take our clients as friends and partners.

Q:How about the installment of the machine and the after-sales service?

A:We offer machine manual and software manual instructions for each set of machine,also offer videos for your reference and 24-hour online technical support.All of these supports are free,we will be there untill you can operate the machine fluently.

A:We offer machine manual and software manual instructions for each set of machine,also offer videos for your reference and 24-hour online technical support.All of these supports are free,we will be there untill you can operate the machine fluently.

Q:How about the shipment of the machine?

A:Usually the machine will be shipped by sea,however we will plan the most suitable shipping way for you according to your requirements.also will consider the budget for you of course.

A:Usually the machine will be shipped by sea,however we will plan the most suitable shipping way for you according to your requirements.also will consider the budget for you of course.

Q: What is the difference between your product and the laser cutting machine?

A: a. Our products are cut with vibrating blades, no laser, no pollution, and create a good

working environment for workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.

A: a. Our products are cut with vibrating blades, no laser, no pollution, and create a good

working environment for workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.