- Overview

- Product Description

- Company Profile

- Packaging & Shipping

Basic Info.

Model NO.

YYKB-IV-160

Weighing System

Electronic Weighing Pan

Control Method

PLC Frequency Controlled

Consumption

Low

Security

High Security

Automatic

High Automatic

Transport Package

Wooden Pallet

Specification

160

Trademark

YINGYANG

Origin

China

HS Code

844900

Production Capacity

300sets/Year

Product Description

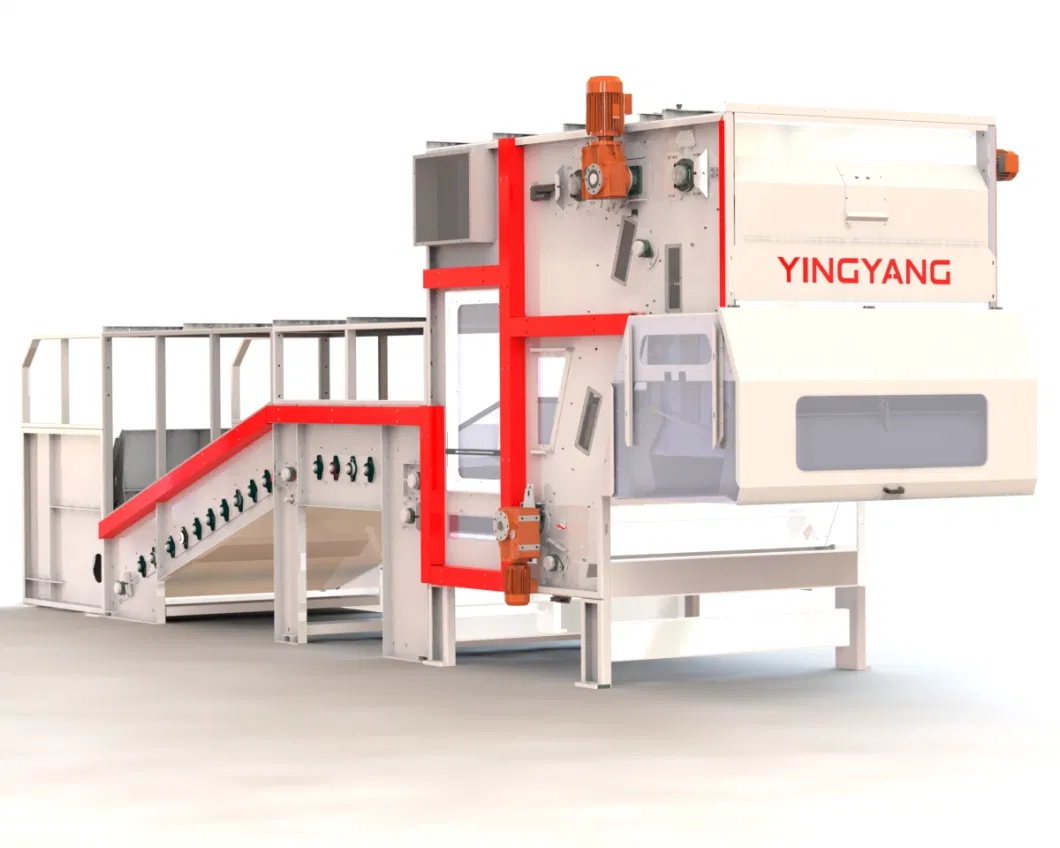

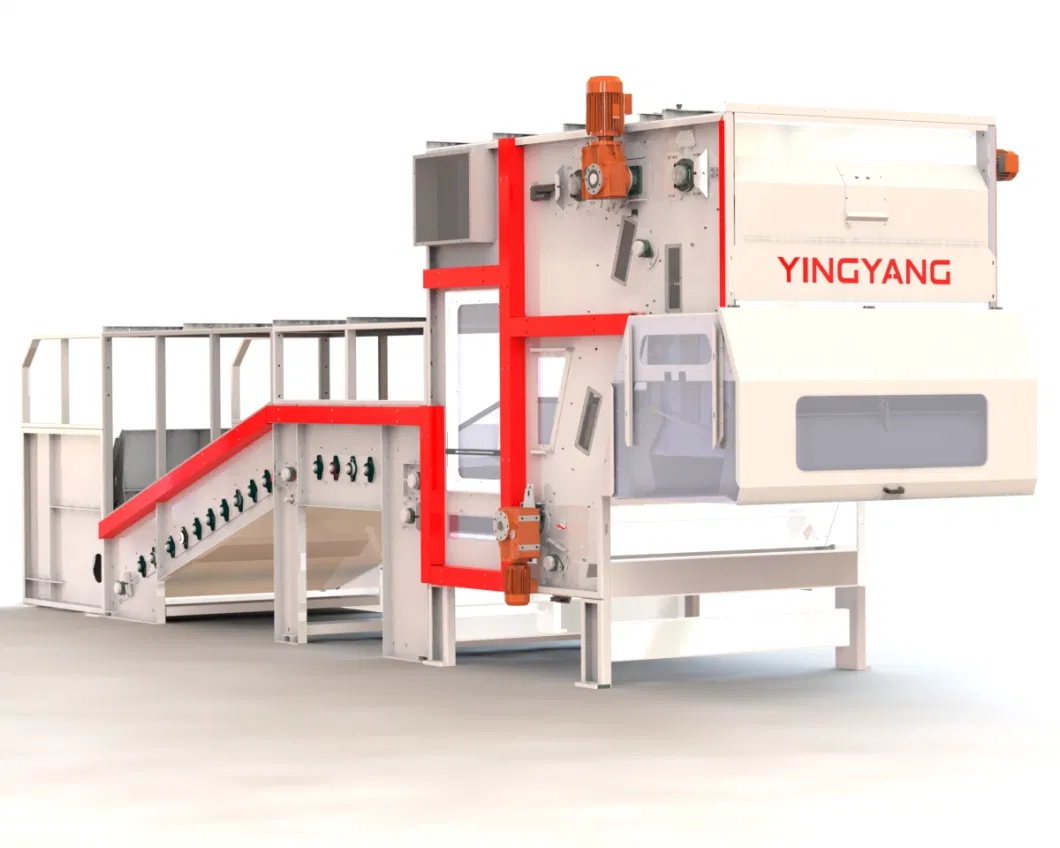

Customized High Security Automatic Non Woven Fabric Carpet Shearing Machine

The machine is used to pre-open baled fiber and prepare the fiber to the next working procedure according to a certainty percentage. And electronic weighing system controls the amount of fiber per dump and in combination with other bale opener units, a number of fiber types can be blended together.

The machine is used to pre-open baled fiber and prepare the fiber to the next working procedure according to a certainty percentage. And electronic weighing system controls the amount of fiber per dump and in combination with other bale opener units, a number of fiber types can be blended together.

Technical data: working width :1600mm

Control method: PLC frequency controlled

Production capacity:400kg/h based on 6D PET fiber

-

- Q235-A steel plates with 8mm thick are cut and welded by computer for machine frame.

- The spiked lattice is made of high quality engineering plastic with canvas interlining and surrounded with angle steel for supporting.

- Conveying lattice is made of two sub-section PVC lattices in high and low dislocation arrangement. With hydraulic bales feeding system.

- The diameter of the fiber average roller and fiber stripping roller are 480mm including the height of the spikes and there are 3 rows in total. Lighter beater and the distance between beater and spiked lattice can be automatically adjusted by linear actuator.

- Feeding is controlled by photo electric automatically and the Spike lattice is controlled by separate inverter to control the feeding amount.

- Larger hopper is made from Aluminum alloy, controlled by air cylinders in the middle. Auto exhaust-driven hoppers. Fiber dropping cannot be affected by airflow. It measures by accurately load cells.

- Cable tray are designed and fixed on the machine.