- Overview

- Product Description

- Product Parameters

- Certifications

- Company Profile

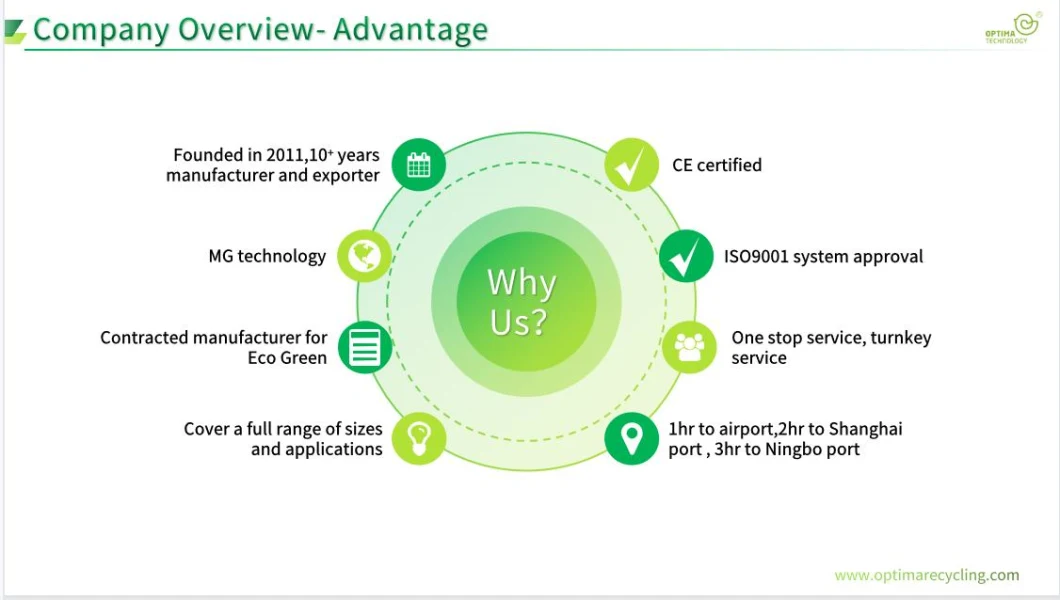

- Our Advantages

- After Sales Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

This series Alligator Cutting Machine is mostly applied in the metal recycled processing plant, disassembling field of scraped vehicles, smelting and casting fields and other industries.

It is able to process the steel section in different shape and diversified waste structural metal like round steel, square steel, angle iron, I steel, plate steel and steel pipe into the qualified furnace charge through cold cutting.

Added with appropriate devices, our product can work as the length shearing equipment for small sized steel section in rolling mill. In general, the hydraulic drive facilitates the automation of the machine.

Depending on diversified control valves and especially the combination of hydraulic and electrical control, this Alligator Cutting Machine easily accomplishes complicated automatic working cycle.

The alligator shear is suitable for the following scrap  Working process

Working process

Features of Tire Debeader* The alligator shearing machine can be operated Individually and continuously.

* The alligator shearing machine is easier to manipulate and maintain.

* The alligator shearing machine's working efficiency is better.

Advantages of the full line waste tyre recycling system

1.Exclusive Control System - Controls and operates the entire plant from its centrally located position and provides instant visibility to what each machine is doing in real time.

2.Unique Stop/Auto Reversal Feature - Protects against overfeeding and damage by non-processable items.

3.Premier Full Turn Key Systems - Plant is manufactured, shipped, installed and ready to start recycling.

4.Warranty - one of the best warrantees in the industry.

| Name: | Crocodile Shearing Scissors |

| Motor: | 15KW-4-380V-50HZ |

| Power: | 76TON,depend on customer's requests |

| Oil pump: | 63YCY |

| Cutting blade length: | 1500mm,depend on customer's requests |

| Weight | 5500kg |

- 2-3 engineers will be sent to help you installing the machine, debugging the machine, training your worker, until your machines working normally and your workforce operate skillfully.

- 1 year warranty for the spare parts and 20 years warranty for the heavy duty machine (without spare part) in normal working process.

- Spare parts delivered at cost in short time to ensure your daily production.

- Life-long maintaining and technical support.

Outstanding Achievement

Q1: How to choose the suitable machine?

A: Please answer first:

a: What material do you want to shred?

b: What is the usage of the crushing material?

c: How many tons per hour do you demand?

After that, the suitable machine could been introduced to you.

Q2: What about the shipping and package?

A: We arrange shipment according to your requirements. It is included in our TURNKEY service.

Q3: Will you send the engineer to guide installation?

A:Yes, according to the customer's requirement, engineers will be sent to guide installation,commisioning and training.

Q4:What make you different from your competitors? Why are you better?

1.We adopt US technology

2.15+ years manufacturer and exporter

3.Construction accurate

4.Welds good

5.PLC control,very easy operation

6.Turnkey service include design,production,logistic,customs,installation,commissioning,etc

Q5:About the after-sale service, how can you solve the problems occurred of your overseas customer in time?

A:The warranty of our machine is normally 12 months, during this period, we will arrange the international express immediately, to make sure the replace parts to be delivered as soon as possible.

Q6: Can you send us the layout and electric drawing?

Files send with machines,including layout drawing, foundation drawing, electrical drawing, manual,packing list,spare parts list,factory test report, installation and maintenance video.