- Overview

- Product Description

- Product Parameters

- Main parts

- Company Profile

- Packaging & Shipping

Basic Info.

Model NO.

JA-D6020

Structure Type

Gantry Type

Laser Classification

Free Electron Laser

Laser Technology

Laser Fusion Cutting

Machine

Metal Processing Machine

Transport Package

Fumigation-Free Plywood Wooden Box

Specification

8650*2950*2000mm

Trademark

JATTRAz(JINGCHUANG LASER)

Origin

China

HS Code

8456110090

Production Capacity

600 Sets/Year

Product Description

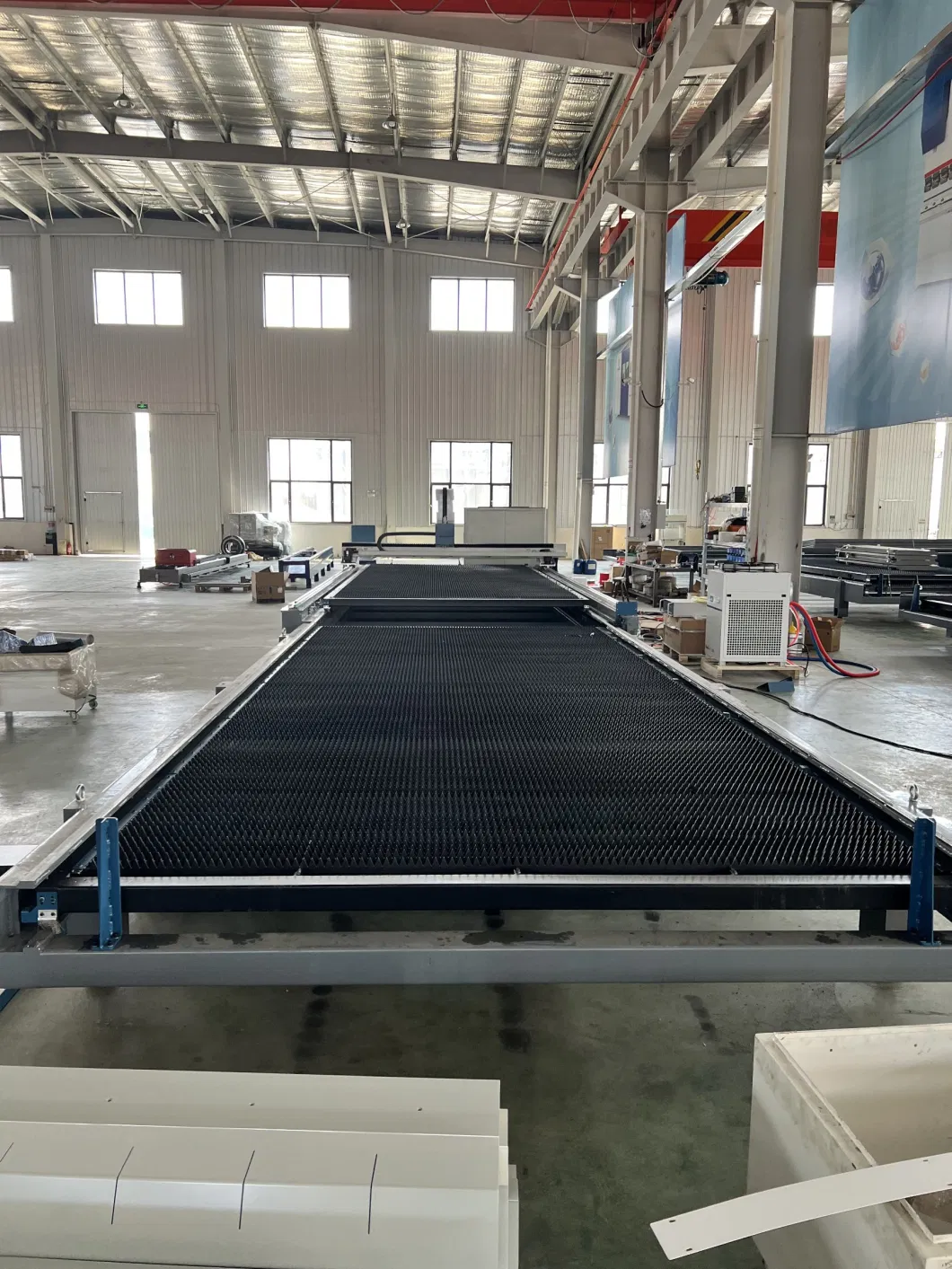

CE High Power Open Tyepe CNC Fiber Laser Cutting Machine with Exchangeable Table for Metal Stainless Steel Carbon Steel Aluminum

Fully enclosed fiber laser cutting machine can cut a variety of metal plates with different thickness, mainly applicable to stainless steel, carbon steel, manganese steel, galvanized plate, alloy plate and other metal materials for rapid cutting.

1.Plate welding bed: welded by 15-20mm manganese steel plate with internal reinforcement to improve the hardness of the bed;

2.Follow-Up partitioning dust collector: effectively absorb dust and impurities, and improve the working environment of the machine;

3.Transmission system error within 0.03mm, by the gantry milling machine finishing processing, cutting process of high accuracy and small error;

4.Independent control cabinet configuration, easy maintenance and reduce component light wave interference, refrigeration to enhance the working life of components;

5.Hollow bed structure, avoid the thermal deformation of the bed caused by heat diffusion in high power work, ensure the long-term precision and stability of the bed;

6.European imported radiation-proof glass, block laser radiation and facilitate monitoring equipment at any time;

7.Large-size equipment with light curtain protection, enhance the safety of equipment operation.

7.Large-size equipment with light curtain protection, enhance the safety of equipment operation.

| JATTRA GROUP(JINGCHUANG LASER) FIBER LASER CUTTING MACHINE JA-D SERIES | ||||||

| Model | JA-D3015 | JA-D4020 | JA-D6025 | JA-D8025 | JA-D12025 | |

| Working Area(mm) | 3000*1500 | 4000*2000 | 6000*2500 | 8000*2500 | 12000*2500 | |

| X/Y Axis Positioning Accuracy | ±0.03mm | |||||

| X/Y Axis Repositioning Accuracy | ±0.02mm | |||||

| Max. Moving Speed | 150m/min | |||||

| Max.Acceleration | 1.5G | |||||

| Laser Power | 1000W-20000W | 2000W-30000W | 2000W-30000W | 6000W-50000W | 12000W-50000W | |

| Laser Source | MAX/ RAYCUS/ IPG (Optional) | |||||

| Laser Cutting Head | OSPRI/ PRECITEC/ RAYTOOLS/BOCI (Optional) | |||||

| Servo Motor | INOVANCE/ YASKAWA (Optional) | |||||

| Control System & Software | CYPCUT | |||||

| Reducer | TAIWAN FASTON | |||||

Machine Body--Heavy Welding Machine Body

The bed adopts a plate-welded integral welding structure, which is rough-processed after annealing to eliminate internal stress, and is finished after secondary vibration aging treatment, which can well solve the stress caused by welding and processing, thereby greatly improving The stability of the machine tool.

The bed adopts a plate-welded integral welding structure, which is rough-processed after annealing to eliminate internal stress, and is finished after secondary vibration aging treatment, which can well solve the stress caused by welding and processing, thereby greatly improving The stability of the machine tool.

Aviation Aluminium Cross-Beam

It is made of 6061 aluminum material, cast into shape, rough machining after annealing to eliminate internal stress, and fine machining after secondary vibration aging treatment.

The net weight of the beam reaches 150 kg, which can effectively withstand higher impacts, ensures the overall strength, rigidity and stability of the beam, and can be adapted to higher power motors

For each beam, we must use a laser collimator to check the beam accuracy to ensure that the beam accuracy is within 0.03mm, otherwise it is a substandard product and will be returned and exchanged.

It is made of 6061 aluminum material, cast into shape, rough machining after annealing to eliminate internal stress, and fine machining after secondary vibration aging treatment.

The net weight of the beam reaches 150 kg, which can effectively withstand higher impacts, ensures the overall strength, rigidity and stability of the beam, and can be adapted to higher power motors

For each beam, we must use a laser collimator to check the beam accuracy to ensure that the beam accuracy is within 0.03mm, otherwise it is a substandard product and will be returned and exchanged.

JINGCHUANG (Tianjin) Laser Technology Co., Ltd. (JATTRA GROUP) started in 2015, the founder comes from the Swiss Bystronic

Group, the company technical team are from more than 10 years of experience in the laser industry. The company uses the most advanced modern industrial technology means engaged in fiber laser cutting machine, fiber laser pipe cutting machine , fiber laser welding machine , CNC bending machine, sheet metal complete sets of related industrial equipment and sales. Products are widely used in precision machinery, auto parts , kitchen hardware, electronic appliances, smart home and many other industries.

CNC metal fiber laser cutting machine

1.Timely delivery. Each machine is arranged with precise assembly steps without any delay.

2.After-sales services and Guarantee. We offer 2 years warranty, during the period, any problem happen, we are responsible to solve. And if any part of the machine was broken, which happens rarely

3.Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

2.After-sales services and Guarantee. We offer 2 years warranty, during the period, any problem happen, we are responsible to solve. And if any part of the machine was broken, which happens rarely

3.Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

After Sales Service

- Free training course at our plant.

- Specialized after-sales service group 24 hours online each day, to provide free technical support by e mail, whatsapp, wechat and so on.

- Machine has been tested and adjusted before delivery, you can use the machine directly after receiving it.

- Providing technical services door to the door: we have professional engineers to offer machine installation commissioning and maintenance if customers pay ticket and related charges(accommodation problem) .(5 days training are free and overtime is 100 USD/Day)

- About installation, because we ship the machine by a full container we won't disassemble too much p arts, the main parts that need to connect is laser source, water chiller and controller. We have detailed manual and videos, if you don't understand, our after-sales service man can guide you hand by hand, video call is available.