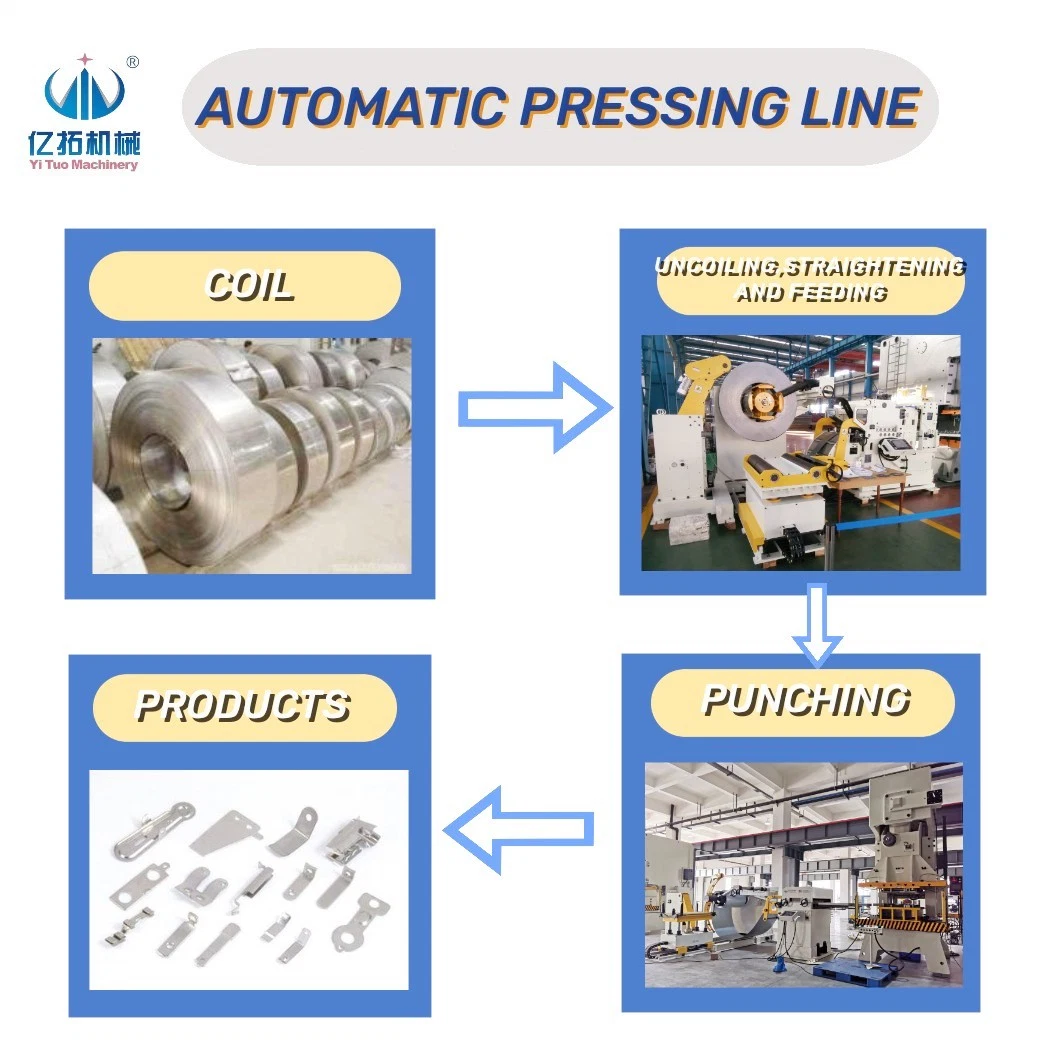

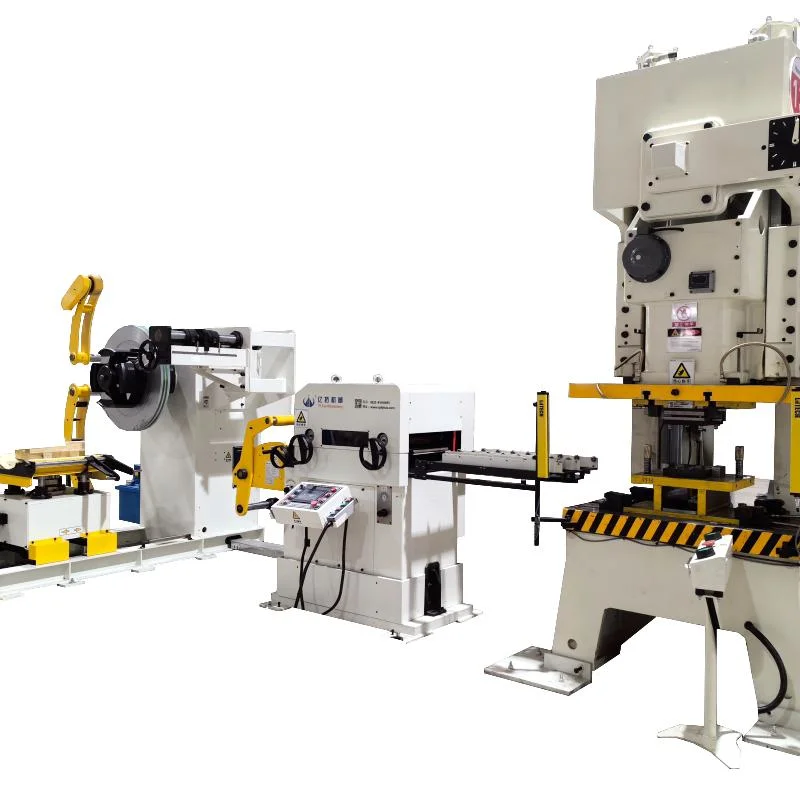

- Overview

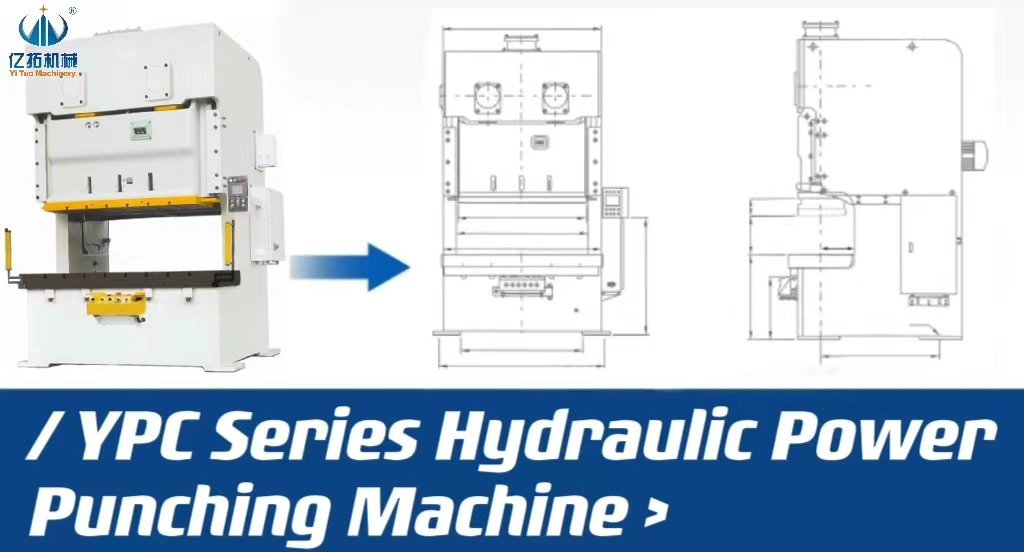

- Product Parameters

- Product Features

- PRODUCT CATEGORY

- Certifications

- COMPANY OVERVIEW

- PACKAGING

- LOADING

Basic Info.

Packaging & Delivery

Product Description

| Type Model | YPA-110 | YPA-130 | YPA-160 | YPA-200 | YPA-260 | YPA-315 | YPA-400 | |||||||||

| V | h | V | h | V | h | V | h | V | h | V | h | V | h | |||

| Nominal Pressure | KN | 1100 | 1300 | 1600 | 2000 | 2600 | 3150 | 4000 | ||||||||

| Nominal Pressure Stroke | mm | 6 | 3 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 8 | 4 | 8 | ||

| Stroke Per minute | variable speed | SPM | 30~60 | 60~90 | 30~60 | 60~90 | 20~50 | 40~70 | 20~50 | 50~70 | 20~40 | 40~50 | 20~40 | 30~50 | 20~35 | |

| Fixed speed Fixed | SPM | 50 | 50 | 35 | 35 | 30 | 30 | 30 | ||||||||

| Upper table size Slide Area | mm | 470×230×50 | 470×230×50 | 470×230×50 | 520×250×50 | 560×300×60 | 700×360×70 | 770×420×70 |

| Lower table size Bolster Area | mm | 680×300×70 | 680×300×70 | 680×300×70 | 800×400×70 | 850×440×80 | 900×500×80 | 1000×550×90 |

| Shank Hole | mm | φ38.1 | φ38.1 | φ38.1 | φ38.1 | φ38.1 | φ50 | φ50 |

Main Motor Power | KW | 2.2 | 4 | 4 | 4 | 5.5 | 5.5 | 7.5 |

Slide Adjust Device | HP | Manual operation | Electric driving | |||||

Air Pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Presses Precision | GB/JIS 1class | |||||||

| (××) Presses Dimension | mm | 830×1236×1920 | 850×1280×2200 | 850×1280×2200 | 900×1380×2400 | 950×1600×2500 | 1000×1600×2800 | 1180×1800×3000 |

Die Cushion Capacity | KN | - | - | - | 23 | 23 | 36 | 36 |

Die Cushion Stroke | mm | - | - | - | 50 | 50 | 70 | 70 |

Die cushion effective area | mm2 | - | - | - | 300×230 | 300×230 | 350×300 | 450×310 |

1. The fuselage is made of high-quality steel plate, designed according to high precision and high strength, and the stress is relieved after welding, so the precision is stable and the performance is reliable.

2. In order to ensure the relative stability of the machine operation, the design method of pneumatic balancer device is adopted.

3. Mould-adjusting precision is as high as 0.1mm, which is safe, convenient and reliable.

4. Crankshafts, gears, screws and other components have undergone hard gasification and grinding treatment, and have extremely high comprehensive mechanical properties and wear resistance.

5. The machine structure design is reasonable and the configuration is complete, which facilitates the realization of automatic production and assembly line production.

6. Using high-performance combined clutch/brake, the combination is stable, safe and reliable.

7. Adopt safety double solenoid valve and hydraulic overload protection device to ensure the maximum safety of production operation.

Q: Are you a factory or trading company?

A: We are a factory which has been producing stamping automation machines for more than 20 years.

Q: What's the delivery time?

A: The standard machine is 25 to 30 working days after payment. For compact coil feed lines or whole metal stamping lines, it needs 30-70 workdays depends on different specifications and production plan in our factory,we will confirm the delivery time based on the specific project itself.

Q: Do you receive OEM or ODM?

A: Yes, we warmly welcome customers to do OEM and ODM in our factory.

Q:What's warranty time of your machine?

A:Usually the warranty time is 12 months. Also the warranty time can be extend acorrding the specific requirements.

Q:What after-sales service does YITUO provide?

A:For the standard decoiler straightener feeder machine, it's easy to install and debug it, most of our customers can do it by themselves; And what's more, our technical engineer can teach your operators how to install and operate it.

For the compact coil feed machine and complete metal stamping line,YITUO can arrange engineers to go overseas for the coil handling equipment installation. They guide the customer's operators on-site.

Q: What information you need to prepare the quotation:

1. Coil thickness (min-max)

2. Coil inner and outer diameter (min-max)

3. What kind of your material

4. Weight of your coils (max)

5. How many tons you need per day or per month