Basic Info.

Model NO.

LJT-2D

Wall Thickness of Paper Tube

10 - 15mm

Certification

CE

Condition

New

Production Speed

15m/Min

Machine Color

White Red

Delivery Time

35days

Machine Warranty

One Year

Voltage

380V 50Hz or Customized

Tube Diameter Range

76-600mm

Transport Package

Pallet

Specification

2D

Trademark

Keepon

Origin

China

HS Code

84418090

Production Capacity

200sets/Year

Product Description

Automatic Spiral Paper Core Tube Winding And Cutting Machine

Video: https://youtu.be/s5x5Yz-iY1Y

Features:

1.Paper tube inside diameter reaches from 76mm to 600mm , the thickness can be up to 15mm (Special made diameter up to 1500mm)

2.Adopt spiral bevel gear, changeable angle, working more stable.

3.Assemble the newest wax-lubrication system, firm the friction between tubes and mandrel, easily control tubes' spiral seam, improve the paper tube's quality.

4.The diameter of drum reaches to 350mm , enlarge the distance and strengthen the tensile. Improve the hardness, the strength and the pressure-proof of the ribbons.

5.Long beam design for using long belt, improve smoothness .

6.Multi-plies paper rack unwinding system.

7.High-speed and low-resistance cutting system.

8.Electric control system designed and installed in line with international standard.

Technical Parameter:

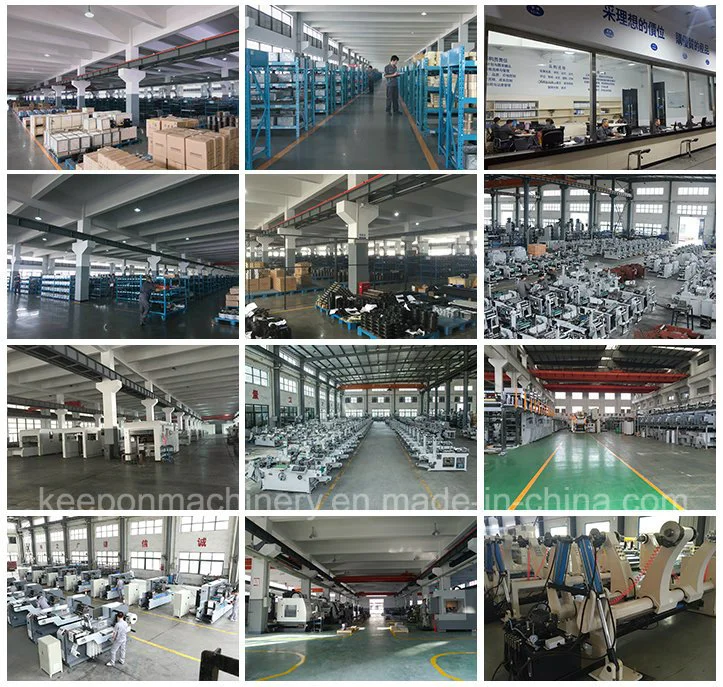

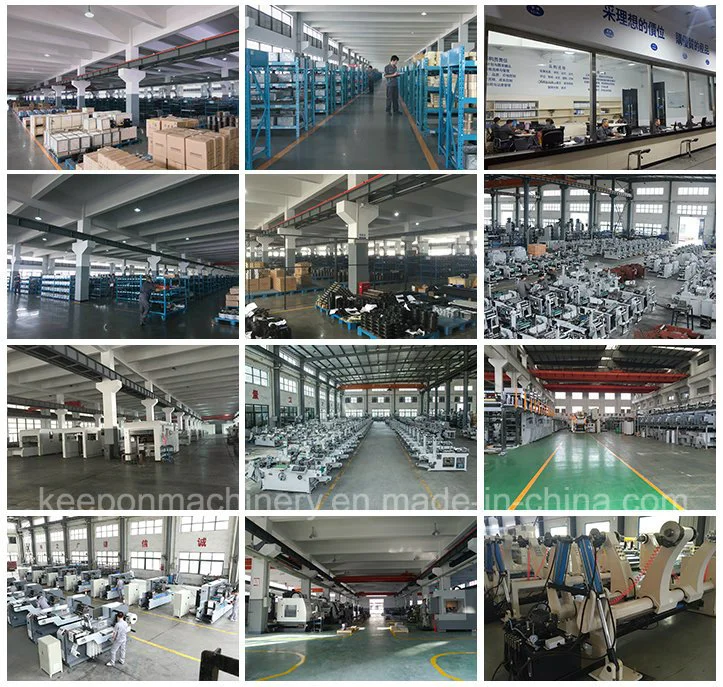

Our Plant View:

Packing And Shipping:

Clients And Exhibition:

FAQ

1. Q: What is your delivery term?

A: FOB,CIF,CFR usually.

2.Q: What is your payment?

A: T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

3.Q: What is your delivery time?

A: 30-50 days usually

4.Q: What is your warranty and other terms?

A: One year machine warranty,and whole life technical support. Spare parts are free for customer in 1 year.

We can send our engineer to your factory for machine installation and operator trainning if you need,

Customer pay the flight tickets,meals and hotel for our engineer.

Salary USD100.00 per day to our engineer.

Video: https://youtu.be/s5x5Yz-iY1Y

Features:

1.Paper tube inside diameter reaches from 76mm to 600mm , the thickness can be up to 15mm (Special made diameter up to 1500mm)

2.Adopt spiral bevel gear, changeable angle, working more stable.

3.Assemble the newest wax-lubrication system, firm the friction between tubes and mandrel, easily control tubes' spiral seam, improve the paper tube's quality.

4.The diameter of drum reaches to 350mm , enlarge the distance and strengthen the tensile. Improve the hardness, the strength and the pressure-proof of the ribbons.

5.Long beam design for using long belt, improve smoothness .

6.Multi-plies paper rack unwinding system.

7.High-speed and low-resistance cutting system.

8.Electric control system designed and installed in line with international standard.

Technical Parameter:

| Applicable thickness | 2-15mm |

| Length of tubes | 1-4mm |

| Speed | 15m/min |

| Power of main machinery | 22KW |

| Size of main machinery | 22KW |

| Size of main machinery | 5000 x 2600 x 2100 mm |

| Special made diameter | up to 1500mm |

Our Plant View:

Packing And Shipping:

Clients And Exhibition:

FAQ

1. Q: What is your delivery term?

A: FOB,CIF,CFR usually.

2.Q: What is your payment?

A: T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

3.Q: What is your delivery time?

A: 30-50 days usually

4.Q: What is your warranty and other terms?

A: One year machine warranty,and whole life technical support. Spare parts are free for customer in 1 year.

We can send our engineer to your factory for machine installation and operator trainning if you need,

Customer pay the flight tickets,meals and hotel for our engineer.

Salary USD100.00 per day to our engineer.