Basic Info.

Product Description

| Product Description |

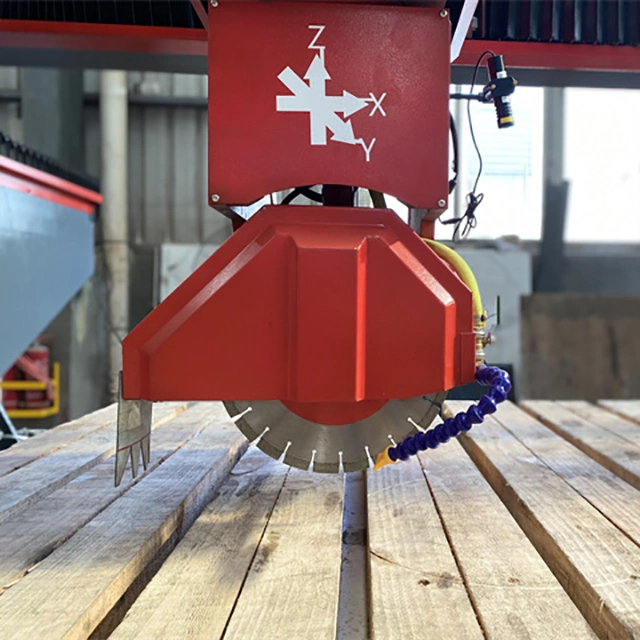

An infrared bridge stone cutting machine is a type of cutting machine that is commonly used in the stone industry to cut and shape natural stone slabs. It uses infrared technology to guide the cutting process, allowing for precise and efficient cuts.

The infrared technology used in the machine involves the use of infrared sensors to detect the edges and contours of the stone slab. These sensors send signals to the cutting blade, which adjusts its position and angle to match the shape of the stone. This results in precise cuts that are consistent in size and shape.

| Machine Features |

1.The machine adopt cast iron on the main part of machine body ensure stability while cutting

2.The cutting speed is controlled by the inverter to achieve stepless adjustment, the head movements, table title up, rotation, and position use hydraulic transmission to move. it can be cut by manually and fully automatic easily.

3.It adopts PLC programmable control system and touch screen operator and combined with high precision encode positioning(Omron brand encoder)

4.The worktable is controlled by hydraulic rotation

5.It is applicable to cutting the valuable and large-sized stone board for many specifications

| Technical Parameters |

| blade diameter | 400-800mm | |||||

| max. vertical stroke | 350mm | |||||

| worktable size | 3200 × 2000mm | |||||

| max cutting depth | 280mm | |||||

| worktable tilt degree | 0-85° | |||||

| worktable rotating degree | 360° optional | |||||

| water consumption | 1.8m³/h | |||||

| motor power | 22kw | |||||

| weight | 5.6t | |||||

| Dimension | 6000 × 4800 × 3000mm | |||||

| After Sales Service |

We provide skilled and rich experience technicians for installation and after-sale service.

| Pre-Sales Service * Inquiry and consulting support. * Configure the best machine line according to customer condition * View our Factory. | After-Sales Service * Training how to install the machine, training how to use the machine. * Engineers available to service machinery overseas. * Lifetime technology maintenance in free and spare parts supply. Related Products |

| Main Parts of the Machine: |

1.Motor: branded motor in China providing stability while cutting

2.Hydraulic station: seven ocean hydraulic system from Taiwan

3.Cement foundation or metallic foundation optional

4.Worktable size: 3000*2000*700mm

5.Rotation: 0-90°and 0-360°(every 45°one rotation) two options & 0-85°tilt

6.Material: adopt #14 Universal Beam instead of #12 box iron, stronger frame to carry stone

7.Inside details: 8 rotation wheels inside the worktable not 6

8.Infrared line to show the cutting path which ensure precise cutting and high cutting quality

| About Us |

Packaging & Loading: |

More Products |

Exhibition Show |

| Our Certificate |

FAQ |

Q. Do you have different quality grades and bonds for different materials?

A. Yes, for more than 10 years, we have accumulated rich experience on diamond tools production. Regular quality grades(A/B/C) and bonds(hard/medium/soft) are available for various types of materials and machines. We can customize product as per special requests(price/dimension) from clients.

Q. Do you offer free samples?

A. Normally we do not offer free sample. But further solutions will be discussed respectively upon request.

Q. If we need technical support, can you offer us?

A. Sure, we have pre-sale and after-sale service team to offer technical support, Well-trained salespersons and engineers are always to ready to respond to your technical doubts.

Q. Are you a manufacturer or trading company?

A. We are a professional stone machinery manufacturing company.We have our own production team and R & D team.

Q. How about the quality of machines?

A. We have our own experienced QC. All machines are manufactured strictly according to the national and international standards.Our machines will be strictly inspected and controlled before delivery.

Q. What is the MOQ ?

A. One set machine