Basic Info.

Packaging & Delivery

Product Description

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

Product Description of Filter Press

Yuwei High Pressure Program Controlled Membrane Filter Press adopts international advanced TPE membrane technology. Materials can be squeezed by water pressure or compressed air, the pressure could up to 0.8-2.0 MPa. Variable filter chamber technology is widely used in solid-liquid separation in chemical, pharmaceutical, mining and other industries to reduce the moisture content of materials and greatly improve production efficiency.

Compared with traditional dehydration equipments, the application of high pressure dewatering technology can achieve the lowest water content of filter cake in sewage dehydration industry, so that the water content of filter cake shall meet the burying or burning standard(water content requirements are different among industries). Moreover, weight and volume of filter cake are reduced by half.

The entire machine can be operated automatically, it could be unattended by equipped with on-line washing and electrical valve or instruments.

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

Membrane Filter Press

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

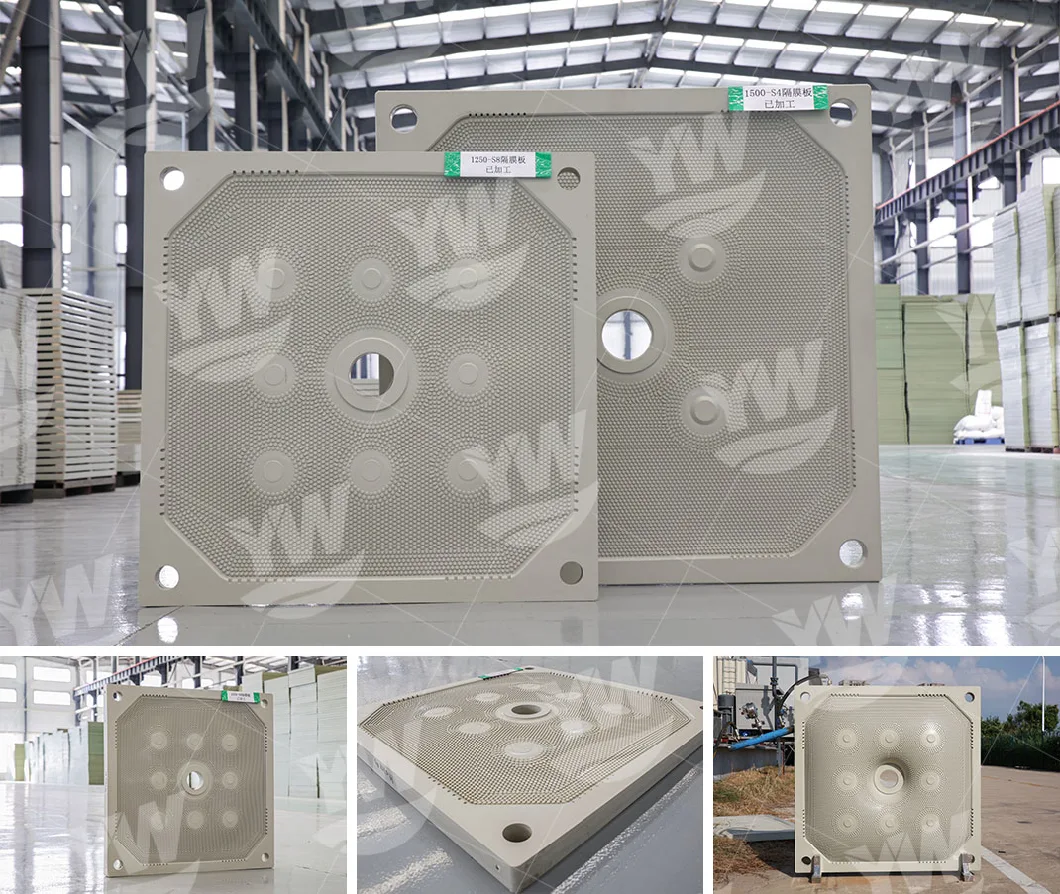

Membrane Filter Plate

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

Specification of Membrane Chamber Filter Press

| Model | Filter Area | Plate size | Volume | Plate QTY | Pressure | Power | Weight | Dimensions |

| G30/870-U | 30m² | 870*870mm | 498L | 23pcs | ≥0.8MPa | 4Kw | 3046Kg | 3880*1250*1300mm |

| G40/870-U | 40m² | 623L | 29pcs | 3593Kg | 4270*1250*1300mm | |||

| G50/870-U | 50m² | 789L | 37pcs | 4057Kg | 4790*1250*1300mm | |||

| G60/870-U | 60m² | 955L | 45pcs | 4597Kg | 5310*1250*1300mm | |||

| G70/870-U | 70m² | 1121L | 53pcs | 5136Kg | 5830*1250*1300mm | |||

| G80/870-U | 80m² | 1287L | 61pcs | 5636Kg | 6350*1250*1300mm | |||

| G50/1000-U | 50m² | 1000*1000mm | 776L | 27pcs | ≥0.8MPa | 4Kw | 4352Kg | 4270*1500*1400mm |

| G60/1000-U | 60m² | 943L | 33pcs | 4480Kg | 4700*1500*1400mm | |||

| G70/1000-U | 70m² | 1109L | 39pcs | 5263Kg | 5130*1500*1400mm | |||

| G80/1000-U | 80m² | 1275L | 45pcs | 5719Kg | 5560*1500*1400mm | |||

| G100/1000-U | 100m² | 1608L | 57pcs | 6555Kg | 6410*1500*1400mm | |||

| G120/1000-U | 120m² | 1941L | 69pcs | 7466Kg | 7260*1500*1400mm | |||

| G80/1250-U | 80m² | 1250*1250mm | 1560L | 29pcs | ≥0.8MPa | 5.5Kw | 10900Kg | 4830*1800*1600mm |

| G100/1250-U | 100m² | 1975L | 37pcs | 11750Kg | 5440*1800*1600mm | |||

| G120/1250-U | 120m² | 2391L | 45pcs | 12600Kg | 6060*1800*1600mm | |||

| G150/1250-U | 150m² | 2911L | 55pcs | 13620Kg | 6820*1800*1600mm | |||

| G160/1250-U | 160m² | 3119L | 59pcs | 14470Kg | 7130*1800*1600mm | |||

| G200/1250-U | 200m² | 3847L | 73pcs | 15320Kg | 8200*1800*1600mm | |||

| G240/1250-U | 240m² | 4679L | 89pcs | 16170Kg | 9420*1800*1600mm | |||

| G250/1250-U | 250m² | 4783L | 91pcs | 17020Kg | 9570*1800*1600mm | |||

| G200/1500-U | 200m² | 1500*1500mm | 3809L | 49pcs | ≥0.8MPa | 11Kw | 26120Kg | 7140*2200*1820mm |

| G250/1500-U | 250m² | 4723L | 61pcs | 26930Kg | 7730*2200*1820mm | |||

| G300/1500-U | 300m² | 5637L | 73pcs | 28160Kg | 8720*2200*1820mm | |||

| G350/1500-U | 350m² | 6551L | 85pcs | 29600Kg | 10110*2200*1820mm | |||

| G400/1500-U | 400m² | 7618L | 99pcs | 31500Kg | 11260*2200*1820mm | |||

| G450/1500-U | 450m² | 8532L | 111pcs | 33400Kg | 12250*2200*1820mm | |||

| G500/1500-U | 500m² | 9446L | 123pcs | 33380Kg | 13240*2200*1820mm | |||

| G600/2000-U | 600m² | 2000*2000mm | 11901L | 85pcs | ≥0.8MPa | 15Kw | 54164Kg | 13030*3000*2500mm |

| G700/2000-U | 700m² | 13838L | 99pcs | 58300Kg | 14390*3000*2500mm | |||

| G800/2000-U | 800m² | 14945L | 107pcs | 62460Kg | 15770*3000*2500mm | |||

| G900/2000-U | 900m² | 17713L | 127pcs | 66620Kg | 17150*3000*2500mm | |||

| G1000/2000-U | 1000m² | 19651L | 141pcs | 70780Kg | 18530*3000*2500mm |

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

Advantage of Membrane Filter Press

- The independently developed high-strength PP filter plate is used,and the compression pressure can reach 22MPa.

- The working process of membrane pressing consumes very short time, saving power consumption.

- Increasing the density of cake and reduce the water content of cake. The membrane squeezes the filtered filter cake for the second time, so that the internal structure of the filter cake is rearranged and the density is increased, thus replacing part of the water, so that the water content is greatly reduced, the drying cost is saved, and the yield is increased.

- It has strong corrosion resistance and is basically applicable to all solid-liquid separation operations.

- It can be configured with PLC and human-computer interface control, and the operation procedure can be adjusted according to the on-site working conditions.

- Membrane filter plate has good toughness, anti-aging and sealing performance to achieve the purpose of aseptic filtration.

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

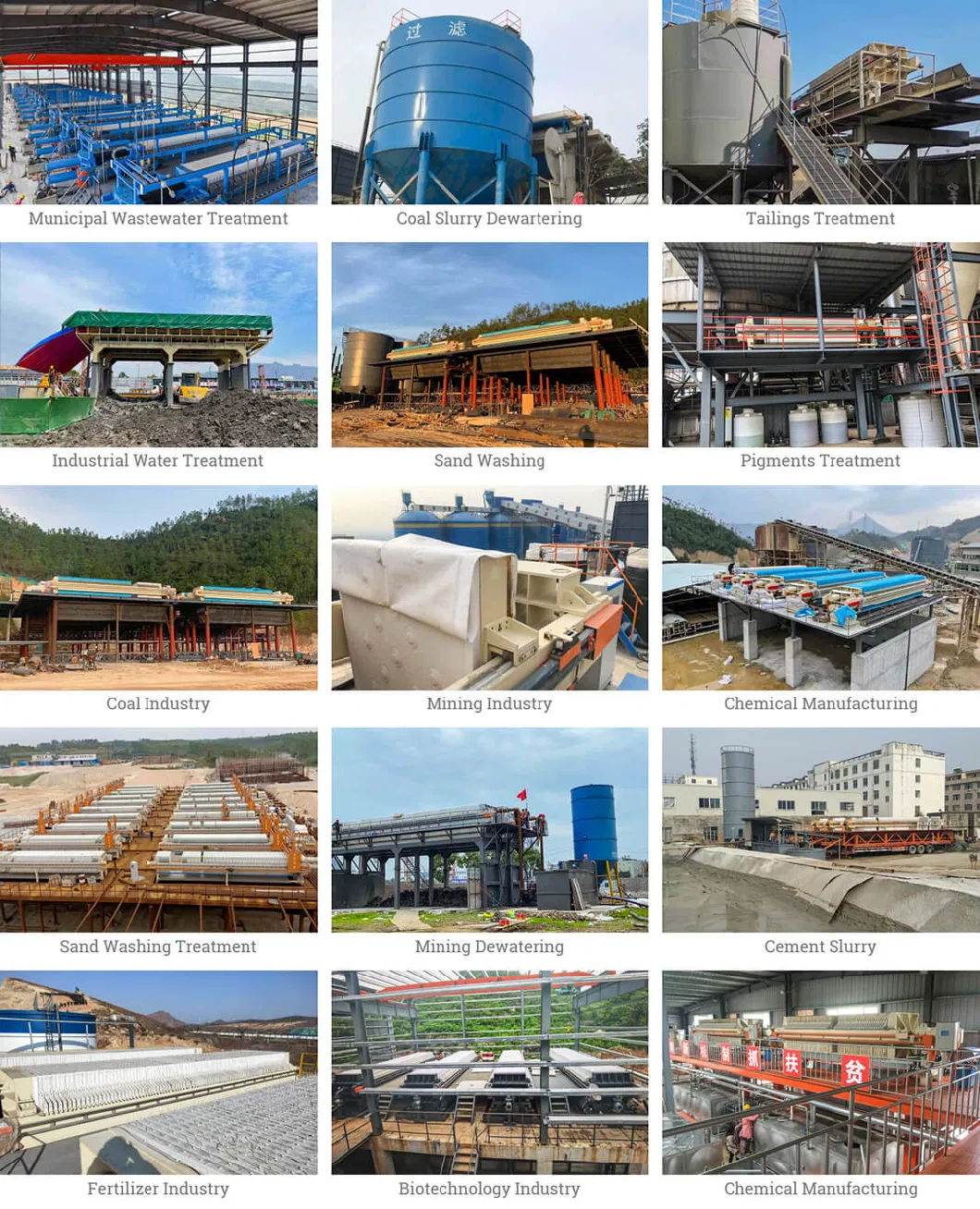

Case of filter press

High Quality Automatic Filter Press Manufacturer Factory Price / Chamber Filter Press / Membrane Filter Press / Plate and Frame Filter Press / Belt Filter Press

Related Products

About Us Yuwei Filter Equipment Co., Ltd. is a filter equipment supplier and engineering solution service provider integrating production, manufacturing, scientific research, sales and international trade. We have advanced production machinery and equipment, professional R&D team and strong production strength, and fully support cutting-edge technology development, mid-term testing, production and after-sales service.

Yuwei Filter Equipment Co., Ltd. is a filter equipment supplier and engineering solution service provider integrating production, manufacturing, scientific research, sales and international trade. We have advanced production machinery and equipment, professional R&D team and strong production strength, and fully support cutting-edge technology development, mid-term testing, production and after-sales service.

We have A wealth of project experience and can provide complete technical guidance and integrated installation services.

CONTACT US

Workshop

Packing & Shipping

FAQ

1. How long is the delivery time of your product?

The delivery time is within 30 working days. But when the crushing plant is big and the customers have special requirement on the crushing plant, the delivery could be extended.

2. What are the payment terms?

The payment term is T/T.

3. How long is the product warranty period?

Our warranty period is 1 year. Wearing parts and problem coursed by worker's wrong operation are not included.

4. What's the after sale service of your company?

We will provide foundation drawing to the clients for intallation. Besides, we can provide guidance service for installation and operation of workers, etc.

5. Can your company provide wearing parts?

We can produce wearing parts for our clients. If your equipment are not manufactured by our company, please provide us the wearing parts drawing.