Basic Info.

Trademark

XINKE

Origin

China

HS Code

8463900090

Product Description

Y32 Hydraulic Drawing Press

Characteristics:

- Computer optimized design, 3-beam&4-column compact structure. With simple, economic and practical

- Cartridge Valve Integrated System equipped in hydraulic control system, and General press below 500t, equipping in hydraulic slider valve control system with high reliability, durability, small hydraulic impact and minimizing hydraulic impact design

- Independent electrical control system with reliability, intuitive movement and convenient amendment

- Adopting Button common control with two operation ways: adjustment or two-hand/single cycle operation

- 5, Preset Stroke Forming or Preset Pressure Forming process can be selected, Pressure holding period can be preset according to requirements

6, Stroke and Pressure can be adjusted within specified scope

Applications:

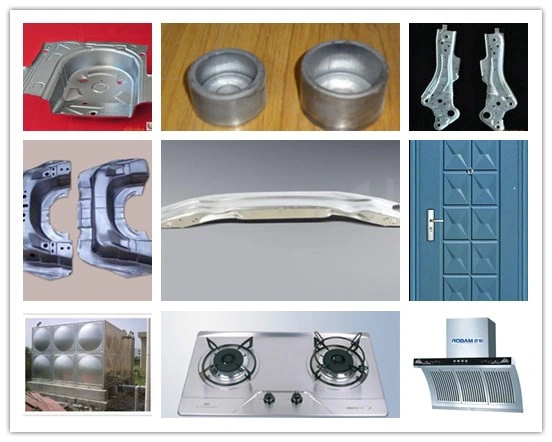

Drawing, bending, flanging, cold extruding, blanking processes for metal materials; Adjusting, press-in and forming processes for powder and abrasive products, plastic and insulation materials

Technical Data:

| Item type | Unit | Y32-100 | Y32-125 | Y32-200 | Y32-315 | Y32-400 | Y32-500 | Y32-630 | Y32-800 | Y32-1000 | Y32-1500 | Y32-2500 | |

| Nominal Pressure | kN | 1000 | 1250 | 2000 | 3150 | 4000 | 5000 | 6300 | 8000 | 10000 | 15000 | 25000 | |

| Ejecting Force | kN | 630 | 630 | 800 | 800 | 800 | 1000 | 1000 | 1250 | 2000 | 2000 | 2500 | |

| Knock-out Force | kN | 160 | 180 | 360 | 450 | 345 | 570 | 850 | 720 | 1600 | 1200 | 2000 | |

| The Max. Pressure of Working Fluid | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| The Max. Stroke of Slider | mm | 630 | 630 | 710 | 800 | 800 | 900 | 1000 | 1000 | 1000 | 1000 | 1000 | |

| The Max. Stroke of Ejector | mm | 200 | 200 | 250 | 300 | 300 | 300 | 300 | 350 | 400 | 400 | 450 | |

| The Max. Opening Height | mm | 900 | 900 | 1120 | 1250 | 1250 | 1500 | 1600 | 1600 | 1600 | 1800 | 1800 | |

| Speed of Slider | Descend | mm/s | 250 | 220 | 160 | 120 | 180 | 150 | 120 | 150 | 150 | 250 | 250 |

| working | mm/s | 12-40 | 9-31 | 7-24 | 8-20 | 10-24 | 10-24 | 8-18 | 8-15 | 5-12 | 8-15 | 8-15 | |

| Return | mm/s | 200 | 200 | 200 | 220 | 220 | 250 | 250 | 250 | 260 | 200 | 200 | |

| Speed of Ejector | Ejecting | mm/s | 60 | 60 | 60 | 75 | 120 | 65 | 65 | 98 | 60 | 50 | 50 |

| Return | mm/s | 125 | 125 | 120 | 150 | 120 | 135 | 135 | 120 | 120 | 120 | 120 | |

| Active Area of Working Table(E×D) | Left-Right | mm | 710 | 710 | 930 | 1260 | 1300 | 1400 | 1880 | 1880 | 2000 | 2500 | 3000 |

| Front-Back | mm | 630 | 630 | 900 | 1200 | 1300 | 1400 | 1600 | 1600 | 1800 | 2000 | 2500 | |

Options:

Cutting Dampening system; Oil heating/cooling unit; Displacement sensor; Industrial touching screen monitor; PLC programmable controller; Floating guide-way and rolling bracket for die exchange; Working area lighting; Quick die clamping device; Light curtain safety device

Electrics: