Basic Info.

Model NO.

NCBF

Certification

ISO9001

Warranty

12 Months

Customized

Customized

Condition

New

Easy to Operate

Parameters Can Be Set up in PLC Touch Screen

Equipped Machine

Stamp Press, Roll Forming Machine, Shear Machine

Thickness Range

0.5-6.0mm

Application Material

Ss, SPHC, SPCC, Gi and So on

Industry

Automotive Parts, Electronics,Home Appliance

Feeding Length

0-9999mm

Feeding Precision

0.02mm

Coil Outer Diameter

1500mm

Coil Inner Diameter

450-530mm

Transport Package

Container

Specification

Woodencase or 20GP or 40GP container

Trademark

YITUO

Origin

Qingdao

HS Code

8462299000

Product Description

Model Description:

NCMF series aggregate frame,correction,one automatic feeding machine feeding the three devices.High-tech,high precision,high efficiency, in the press surrounding equipmentseries products can be said to be the best. The advantages ofthis equipment is to much such as, space saving, durable, simple, and expertise, especially width, are particularly effective in thicker materials, in the same industrial sector is considered the most advanced automatic feeding device.

Today's highly sophisticated knowledge and technology with the

continuous rapid development of industry, the Companyactively stamping series of research and development, to achievelower labor costs, increase productivity, improve quality and other aspects of the improvement. The company manufacture a range of automatic feeder is subject to stringent quality control, product quality and high precision.1

Features of this machine

1. Suitable all kinds of metal sheet straightening nd feeding

2. Suitable for metal parts.electron,electrical appliance,toy and auto parts continuous pressing production,straightening and feeding.

3. Servo motor of this machine, electrical box and some other parts are from Japanwith less malfunction and long using time

4. Chrome plate,high precision, more durable.

5. Input feeding length, easy operation, safe and high stability

Straightening capacity diagram

1. This diagram is suitable for condition,which material stretch intensity is 40kgf/ mm.

2. Straightening capacity may be change because of different actual condition.

3. About coil outer diameter,material width and deciliter standard load weight,please refer to deciliter attachment diagram of this catalogue.

4. About particular specification manufacturing, please contact us.

Specifications

Specification Capacity

Customer's Application

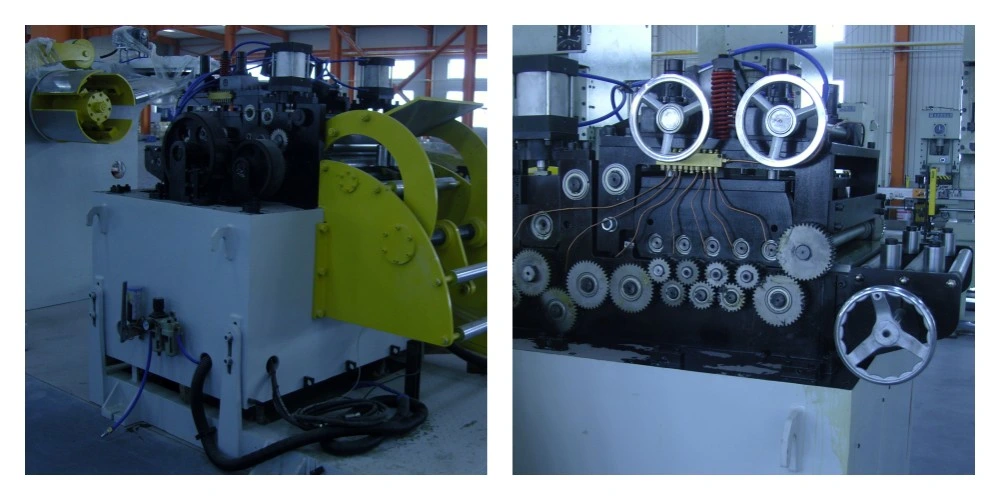

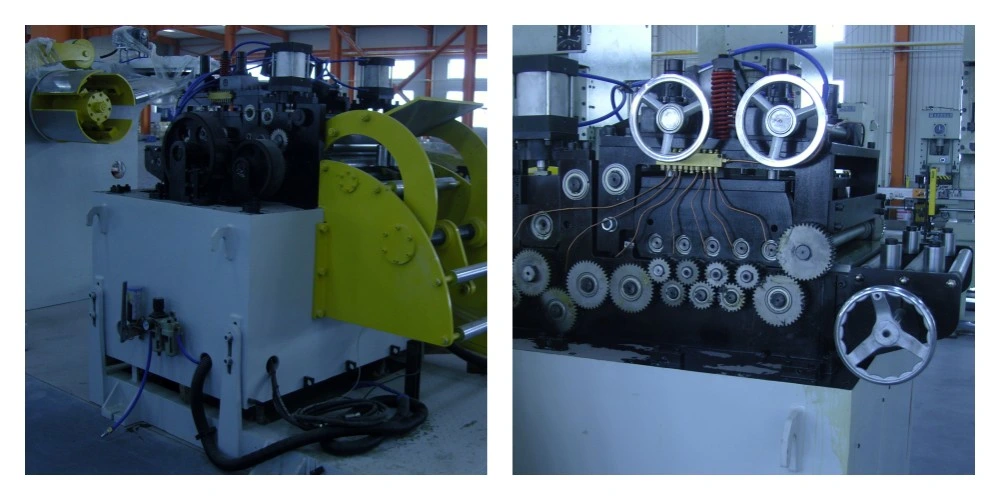

NCMF series decoiler straightener and feeder machine is testing in our factory and working in customer's factory.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing stamping automation machines for more than 20 years.

Q: What's the delivery time?

A: The standard machine is 25 to 30 working days after payment. For compact coil feed lines or whole metal stamping lines, it needs 30-70 workdays depends on different specifications and production plan in our factory,we will confirm the delivery time based on the specific project itself.

Q: Do you receive OEM or ODM?

A: Yes, we warmly welcome customers to do OEM and ODM in our factory.

Q:What's warranty time of your machine?

A:Usually the warranty time is 12 months. Also the warranty time can be extend acorrding the specific requirements.

Q:What after-sales service does YITUO provide?

A:For the standard decoiler straightener feeder machine, it's easy to install and debug it, most of our customers can do it by themselves; And what's more, our technical engineer can teach your operators how to install and operate it.

For the compact coil feed machine and complete metal stamping line,YITUO can arrange engineers to go overseas for the coil handling equipment installation. They guide the customer's operators on-site.

Q: What information you need to prepare the quotation:

1. Coil thickness (min-max)

2. Pipe diameter (min-max)

3. What kind of your material

4. Weight of your coils (max)

5. How many tons you need per day or per month

OUR WORKSHOP AND PACKING:

NCMF series aggregate frame,correction,one automatic feeding machine feeding the three devices.High-tech,high precision,high efficiency, in the press surrounding equipmentseries products can be said to be the best. The advantages ofthis equipment is to much such as, space saving, durable, simple, and expertise, especially width, are particularly effective in thicker materials, in the same industrial sector is considered the most advanced automatic feeding device.

Today's highly sophisticated knowledge and technology with the

continuous rapid development of industry, the Companyactively stamping series of research and development, to achievelower labor costs, increase productivity, improve quality and other aspects of the improvement. The company manufacture a range of automatic feeder is subject to stringent quality control, product quality and high precision.1

Features of this machine

1. Suitable all kinds of metal sheet straightening nd feeding

2. Suitable for metal parts.electron,electrical appliance,toy and auto parts continuous pressing production,straightening and feeding.

3. Servo motor of this machine, electrical box and some other parts are from Japanwith less malfunction and long using time

4. Chrome plate,high precision, more durable.

5. Input feeding length, easy operation, safe and high stability

Straightening capacity diagram

1. This diagram is suitable for condition,which material stretch intensity is 40kgf/ mm.

2. Straightening capacity may be change because of different actual condition.

3. About coil outer diameter,material width and deciliter standard load weight,please refer to deciliter attachment diagram of this catalogue.

4. About particular specification manufacturing, please contact us.

Specifications

| Model | NCBF-400 | NCBF-500 | NCBF-600 | NCBF-700 | NCBF-800 | NCBF-1000 | |

| Ltem | |||||||

| Material thickness | 0.5-6.0(Straighteningrollerl68x4up/3down) | ||||||

| Material width | mm | 400 | 500 | 600 | 700 | 800 | 1000 |

| Coil Inner diameter | mm | ф450~Ф530 | ф450~Ф530 | ф450~Ф530 | ф450~Ф530 | ф450~Ф530 | ф450~Ф530 |

| Coilouter diameter | mm | Ф1500 | Ф1500 | Ф1500 | Ф1500 | Ф1500 | Ф1500 |

| Coil weight | kg | 2000 | 3000 | 5000 | 5000 | 5000 | 5000 |

| Decoiler power | HP | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 |

| Straightening power | kw | 4.4 | 4.4 | 5.5 | 5.5 | 5.5 | 7.5 |

| Expansion style | Hydraulic expansion | Hydraulic expansion | Hydraulic expansion | Hydraulic expansion | Hydraulic expansion | Hydraulic expansion | |

| Size | m | 4.5x1.9x1.8 | 4.5x2.0x1.8 | 4.5x2.1x1.8 | 4.5x2.3x1.8 | 4.5x2.5x1.8 | 4.5x2.8x1.8 |

| Weight | kg | ~3200 | ~3900 | ~4800 | ~5100 | ~5600 | ~6200 |

Specification Capacity

| Model | 400 | 500 | 600 | 700 | 800 | 1000 | |

| Material thickness | |||||||

| 2.0 | 400 | 500 | 600 | 700 | 800 | 1000 | |

| 2.5 | 400 | 500 | 600 | 700 | 750 | 850 | |

| 3.0 | 300 | 380 | 450 | 500 | 600 | 700 | |

| 3.5 | 200 | 300 | 450 | 550 | 550 | 600 |

Customer's Application

NCMF series decoiler straightener and feeder machine is testing in our factory and working in customer's factory.

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing stamping automation machines for more than 20 years.

Q: What's the delivery time?

A: The standard machine is 25 to 30 working days after payment. For compact coil feed lines or whole metal stamping lines, it needs 30-70 workdays depends on different specifications and production plan in our factory,we will confirm the delivery time based on the specific project itself.

Q: Do you receive OEM or ODM?

A: Yes, we warmly welcome customers to do OEM and ODM in our factory.

Q:What's warranty time of your machine?

A:Usually the warranty time is 12 months. Also the warranty time can be extend acorrding the specific requirements.

Q:What after-sales service does YITUO provide?

A:For the standard decoiler straightener feeder machine, it's easy to install and debug it, most of our customers can do it by themselves; And what's more, our technical engineer can teach your operators how to install and operate it.

For the compact coil feed machine and complete metal stamping line,YITUO can arrange engineers to go overseas for the coil handling equipment installation. They guide the customer's operators on-site.

Q: What information you need to prepare the quotation:

1. Coil thickness (min-max)

2. Pipe diameter (min-max)

3. What kind of your material

4. Weight of your coils (max)

5. How many tons you need per day or per month

OUR WORKSHOP AND PACKING: