Basic Info.

Customized

Customized

Advantage

Use Widely

Condition

New

Transport Package

Standrad

Specification

1650*800*1780

Trademark

YSDCNC

Origin

Nanjing

HS Code

8462490000

Production Capacity

600sets

Product Description

aluminium plate hydraulic punching and shearing machine for sale

ironworker

YSD duct production machines are: automatic duct production line, CNC Angle steel flange production line, double (single)linkage TDF flange machine, Angle code mould, plasma cutting machine, seven functions locking machine, manual( pneumatic )crimping machine, five lines (seven lines) beading machine, Angle crimping machine, reel shear beading machine ,leveling bending machine,steel-bend type,horizontal shrimp bend machine,pneumatic joint machine,Angle setter,bias samsung rolling machine.

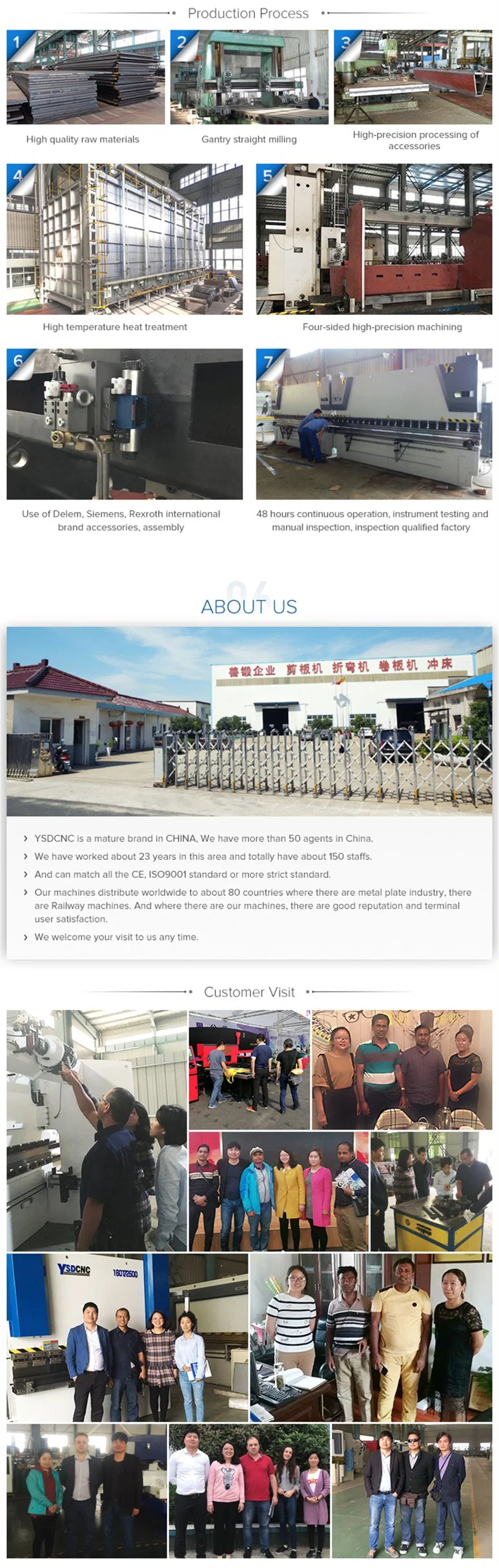

1.Introduction to the structure and properties:

Q35Y Series hydraulic combined punching&shearing machine can cut and punch all kinds of materials such as plate, square bar, angle, round bar, channel and so on.

YSDCNC Brand hydraulic ironworkers have been designed and built to the highest quality standards in the industry. This profitable machine will serve any grueling fabrication shop for decades to come. This machine is typically in stock for quick deliveries.

2.Equipment's working environment:

1 Power supply:3Ph AC 220V/380/415 ± 10%, 50/60 HZ, optional to site.

2 ambient temperature:-10 ºC ~ 45 ºC

3.Main functions:

1)Punching: Full range of universal punches and dies are available.unique style allows for large angle iron punching and large channel punching.Large viewing window on stripper swing away design for ease of operation.large two piece gauging table with rulers and stop as standard fittings.

Quick change coupling nut and sleeve for rapid replacement of change.

2)Shearing: Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar,channel/beam cutting. Large strong guarding for max safety. The angle shear has the ability to cut angle at 45°both top and bottom leg.

This gives the operator the ability to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity. Easily adjustable hold-down device for accurate plate cutting.Large 15″squaring arm with inlaid scale.

Special anti-distorted blade for quality cutting. Lower blade has four usable edges.There is screw allow for gap adjust no shim needed.

3)Notching: Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.The notching section of this hydraulic ironworker is perfect for notching out metal plate, angle iron and much more.

The notching station also has an over sized table with material stops. This section of the machine can also be outfitted with the optional vee notcher.

4)Bending: Also bend the plate below 500mm. All the components of Machine are of the highest quality in their safety, function.

ironworker

ironworker

YSD duct production machines are: automatic duct production line, CNC Angle steel flange production line, double (single)linkage TDF flange machine, Angle code mould, plasma cutting machine, seven functions locking machine, manual( pneumatic )crimping machine, five lines (seven lines) beading machine, Angle crimping machine, reel shear beading machine ,leveling bending machine,steel-bend type,horizontal shrimp bend machine,pneumatic joint machine,Angle setter,bias samsung rolling machine.

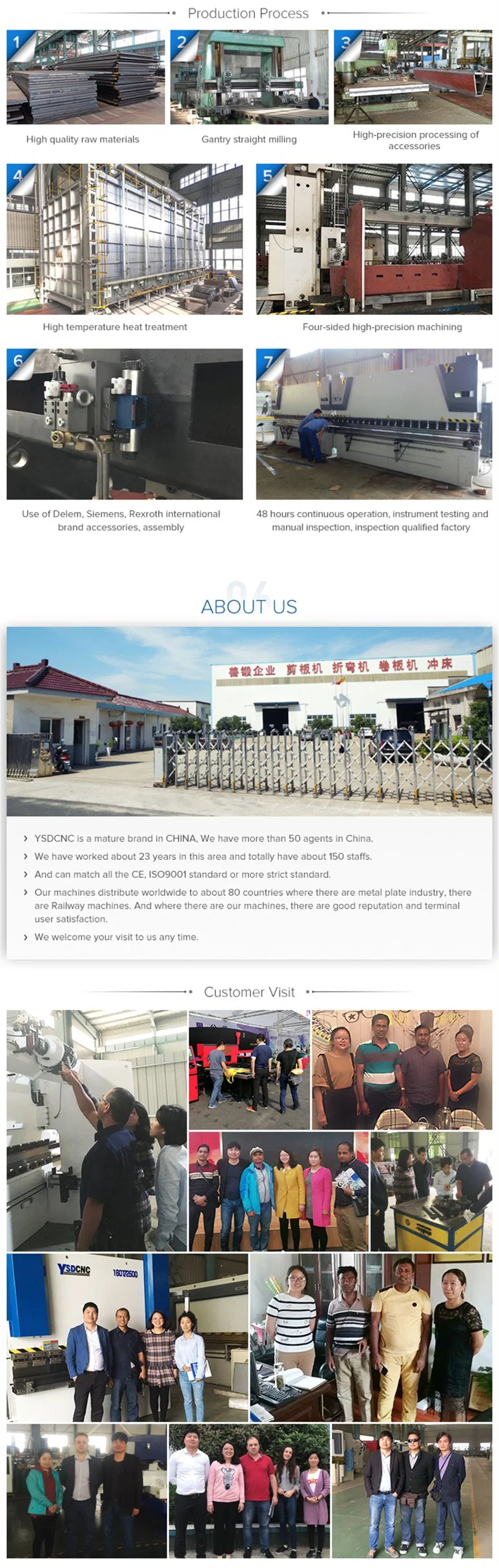

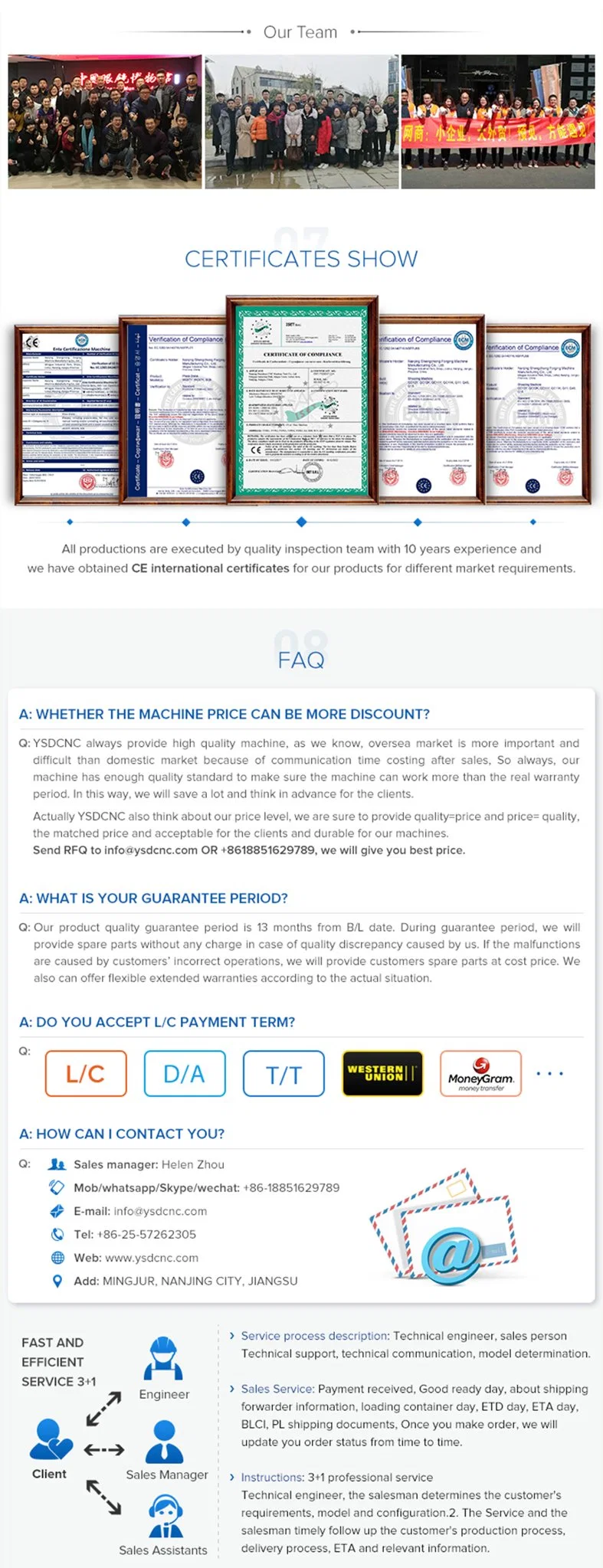

| Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

| Brand: YSDCNC |

| Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

| Tel:+86 025-57262305 Phone:+86 18851629789 |

| Website: www.ysdcnc.com |

1.Introduction to the structure and properties:

Q35Y Series hydraulic combined punching&shearing machine can cut and punch all kinds of materials such as plate, square bar, angle, round bar, channel and so on.

YSDCNC Brand hydraulic ironworkers have been designed and built to the highest quality standards in the industry. This profitable machine will serve any grueling fabrication shop for decades to come. This machine is typically in stock for quick deliveries.

2.Equipment's working environment:

1 Power supply:3Ph AC 220V/380/415 ± 10%, 50/60 HZ, optional to site.

2 ambient temperature:-10 ºC ~ 45 ºC

| Type Item | Unit | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | |

| Punching Pressure | Ton | 60 | 90 | 110 | 140 | 180 | |

| Plate strength | N/mm² | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

| Angle of shear | ° | 7° | 8° | 8° | 8° | 8° | |

| A trip size | Thickness | mm | 16*250 | 20*330 | 25*330 | 30*355 | 35*400 |

| Width | mm | 8*400 | 10*480 | 20*600 | 20*600 | 25*700 | |

| Slide stroke | mm | 80 | 80 | 80 | 80 | 80 | |

| Slide strokes Per Minute | times/min | 8 | 8 | 8 | 8 | 8 | |

| Tnroat Depth | mm | 300 | 355 | 400 | 600 | 600 | |

| Punch Depth | Thickness | mm | 16 | 20 | 25 | 28 | 35 |

| Dia | mm | Φ25 | Φ30 | Φ35 | Φ38 | Φ40 | |

| Motor Power | KW | 4 | 5.5 | 7.5 | 11 | 15 | |

| Dimension | L | mm | 1650 | 1950 | 2350 | 2680 | 2770 |

| W | mm | 800 | 900 | 980 | 1060 | 1240 | |

| H | mm | 1780 | 1930 | 2100 | 2380 | 2350 | |

| Weight | KG | 1600 | 2300 | 4200 | 6000 | 6800 | |

| Shear profile specification: | |||||||

| Type Item | Unit | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | |

| Round steel | mm | 45 | 50 | 60 | 65 | 70 | |

| Square steel | mm | 40*40 | 50*50 | 50*50 | 55*55 | 60*60 | |

| Equilateral angle | 90 °shear | mm | 125*125*12 | 140*140*12 | 160*160*14 | 180*180*16 | 200*200*18 |

| 45°shea | mm | 50*50*5 | 50*50*5 | 60*60*6 | 60*60*6 | 100*100*10 | |

| Industrial steel | mm | 126*74*5 | 160*86*6 | 200*102*9 | 280*124*10.5 | 300*126*11 | |

| Channel steel | mm | 126*53*5.5 | 160*60*6.5 | 200*75*9 | 280*86*11.5 | 300*89*11.5 | |

3.Main functions:

1)Punching: Full range of universal punches and dies are available.unique style allows for large angle iron punching and large channel punching.Large viewing window on stripper swing away design for ease of operation.large two piece gauging table with rulers and stop as standard fittings.

Quick change coupling nut and sleeve for rapid replacement of change.

2)Shearing: Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar,channel/beam cutting. Large strong guarding for max safety. The angle shear has the ability to cut angle at 45°both top and bottom leg.

This gives the operator the ability to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity. Easily adjustable hold-down device for accurate plate cutting.Large 15″squaring arm with inlaid scale.

Special anti-distorted blade for quality cutting. Lower blade has four usable edges.There is screw allow for gap adjust no shim needed.

3)Notching: Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.The notching section of this hydraulic ironworker is perfect for notching out metal plate, angle iron and much more.

The notching station also has an over sized table with material stops. This section of the machine can also be outfitted with the optional vee notcher.

4)Bending: Also bend the plate below 500mm. All the components of Machine are of the highest quality in their safety, function.

ironworker