- Overview

- Product Description

- Features

- Product Parameters

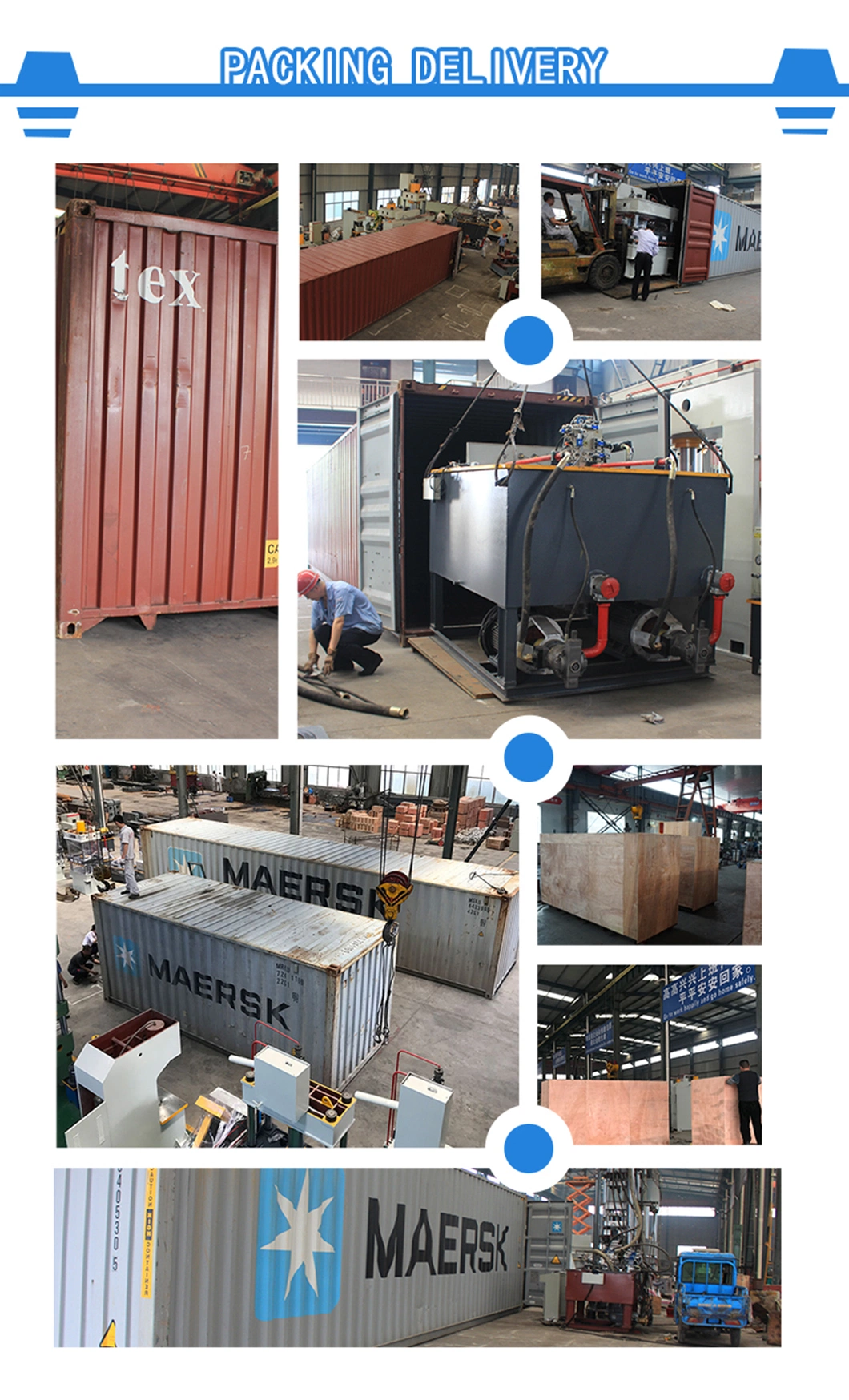

- Packaging & Shipping

- Company Profile

- Customer Visit

- Our Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

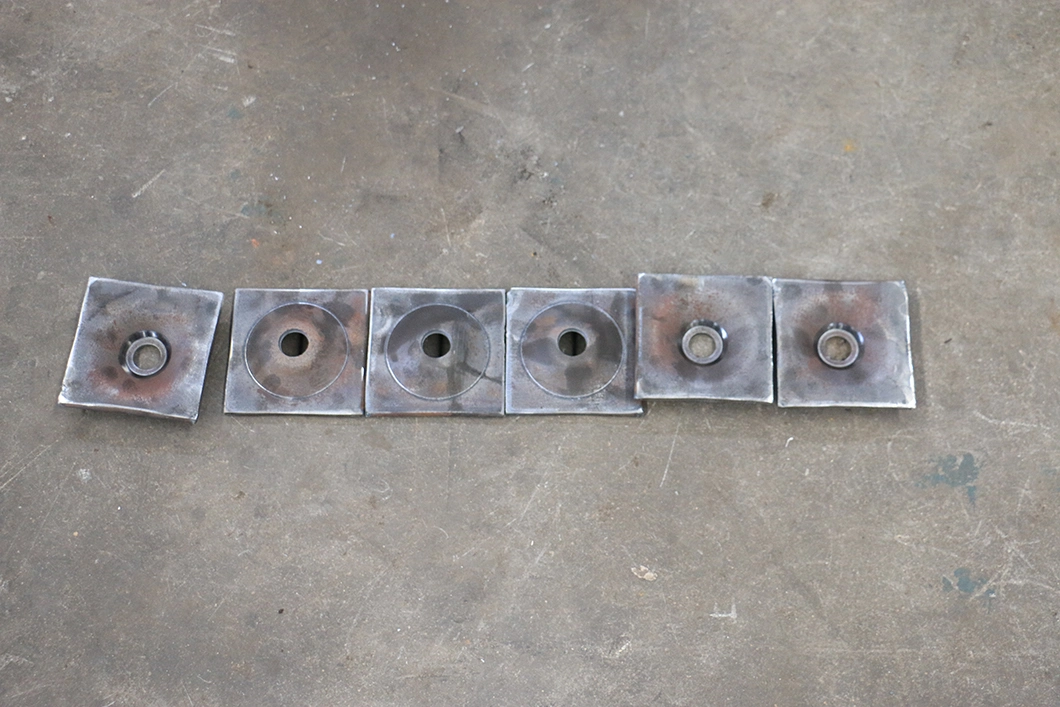

The Nadun 160-ton metal punching machine is a high-productivity, precision punch press with a 5.5-inch stroke length. It has a 160-ton punching force capacity and is equipped with a 3-phase motor. The machine meets CE quality standards and is ISO-certified. Key features include high speed, durability, accuracy, and safety. This industrial punch press is designed for demanding production environments where reliability and precision are essential.

The Nadun 160-ton metal punching machine is a high-productivity, precision punch press with a 5.5-inch stroke length. It has a 160-ton punching force capacity and is equipped with a 3-phase motor. The machine meets CE quality standards and is ISO-certified. Key features include high speed, durability, accuracy, and safety. This industrial punch press is designed for demanding production environments where reliability and precision are essential.

Model

High punching force capacity of 160 tons for punching a wide range of metal materials

Large 5.5-inch stroke length allows the machine to produce complete parts in a single stroke

High productivity design with fast punching speed optimizes workflow efficiency

Precision machined construction ensures accuracy and consistency for every punch

Equipped with a 3-phase motor providing reliable power transmission

CE marked for proven quality that meets rigorous European standards

ISO certified for globally recognized quality assurance

Durable construction stands up to high-volume production demands

Advanced safety features like two-hand operation maximizes operator protection

Designed for 24/7 operation with minimal maintenance requirements

Ideal for demanding production environments requiring high up-time and precision

| SPECIFICATION | Unit | YC21-100T | YC21-125T | YC21-160T | YC21-200T | YC21-315T |

| Max system pressure | Mpa | 25 | 25 | 25 | 25 | 25 |

| Max. Open height | mm | 320 | 320 | 350 | 400 | 500 |

| Effective stroke | mm | 140 | 140 | 160 | 180 | 220 |

| Table effective area(LRXFB) | mm | 1100×710 | 1200×720 | 1300×740 | 1400×760 | 1600 ×800 |

| Throat depth | mm | 380 | 380 | 380 | 400 | 420 |

| Slider stroke times per minute | times/min | 30 | 30 | 30 | 20 | 20 |

| slider size | mm | 560x420 | 560×420 | 770×580 | 770×580 | 850×650 |

| slider mould hole size | mm | 60 | 60 | 65 | 65 | 70 |

| Blanking hole size of table | mm | 220 | 220 | 260 | 260 | 280 |

| Distance between floor and table | mm | 870 | 870 | 870 | 900 | 920 |

| Motor | kw | 7.5 | 11 | 15 | 18.5 | 30 |

| Weight | T | 6 | 9 | 11 | 14.5 | 26 |

| Oil tank capacity | L | 350 | 400 | 500 | 700 | 900 |

Internal plastic moisture-proof anti-rust packaging, External wooden packaging, Exclusive container transport.

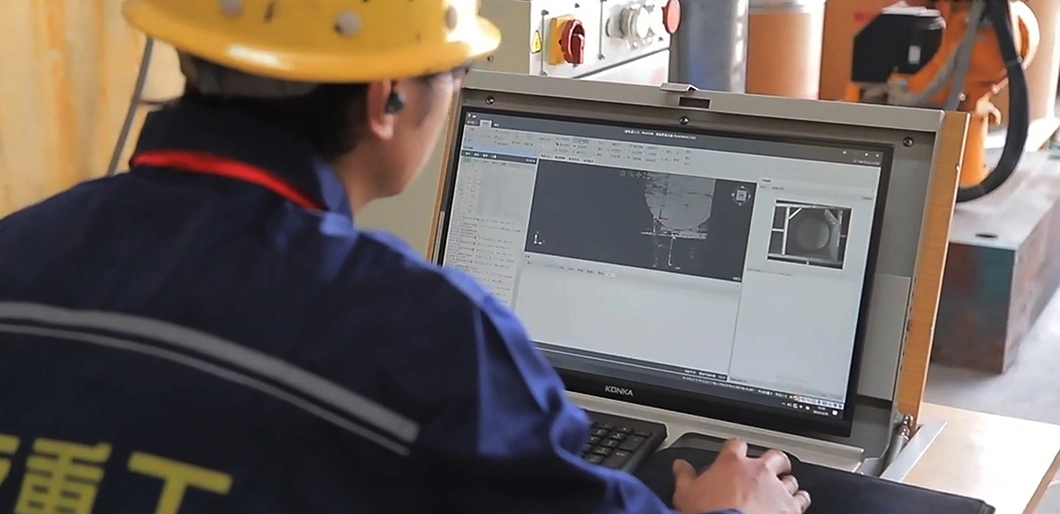

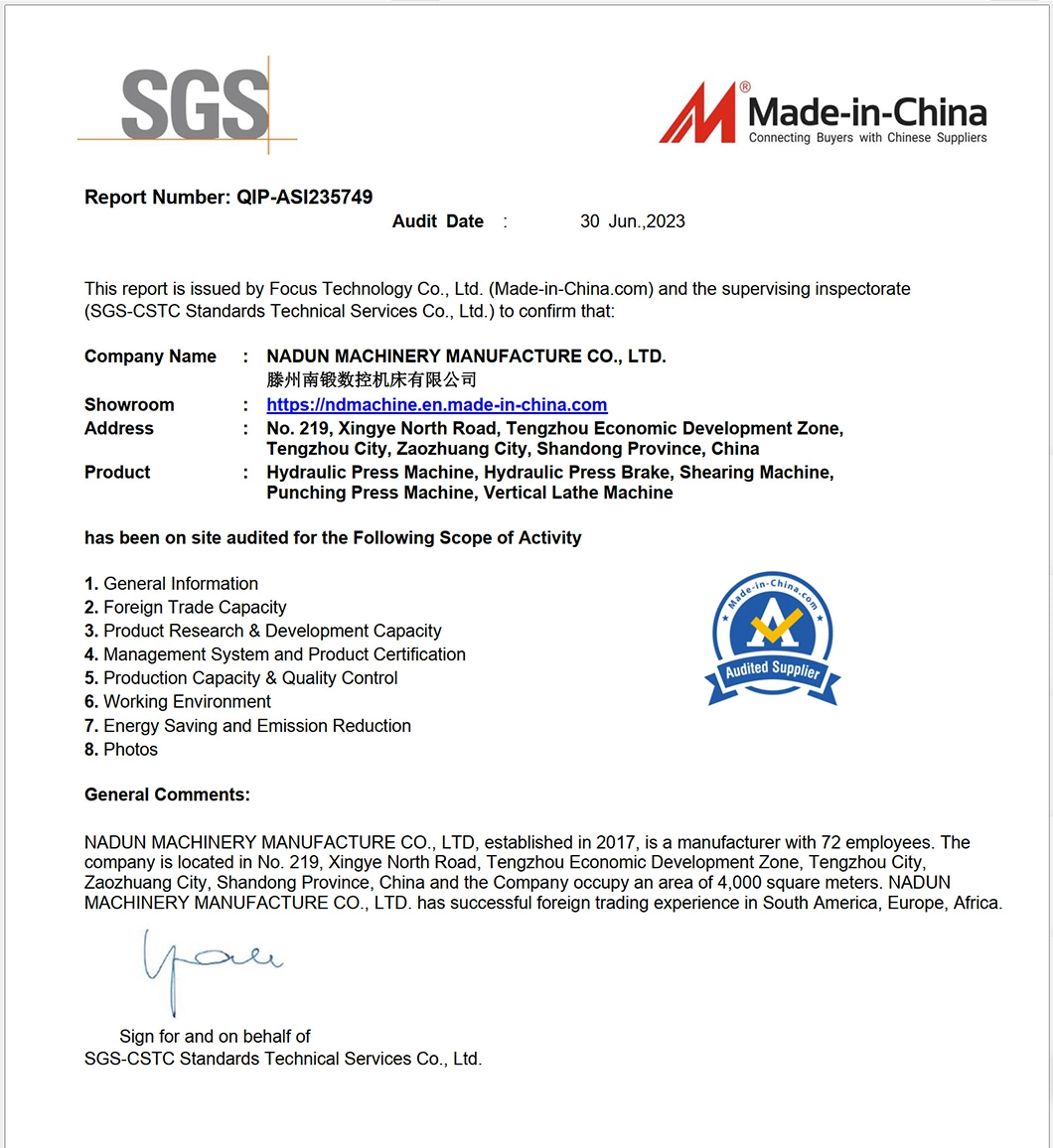

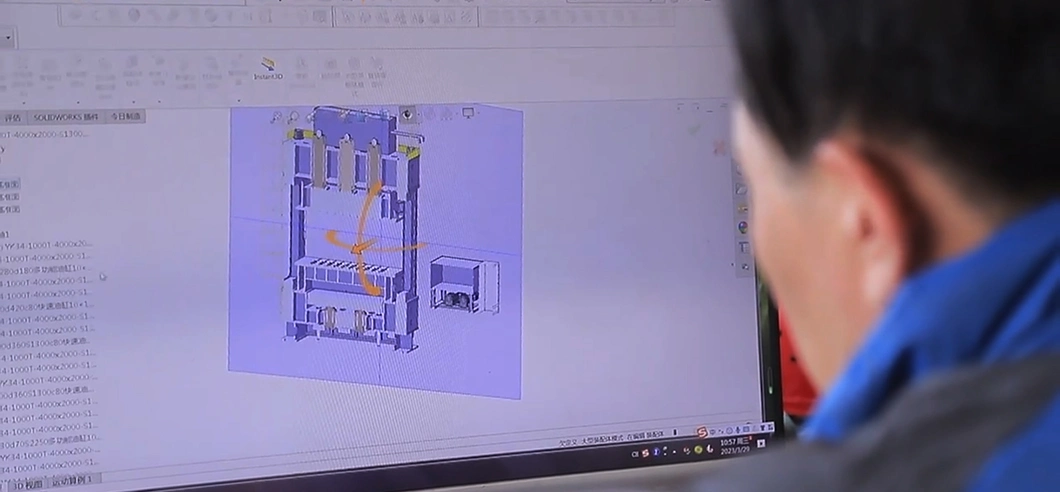

The company's processing equipment includes large-scale CNC floor-standing boring and milling machines, CNC gantry machining centers and other advanced equipment. Our company has passed the ISO,CE,SGS and other certification,has a number of product innovation patents and honorary certificates. Our main products include manual lathe,cnc lathe,saw machines,machine tool,Drill machine, Milling machine,Machining Center,CNC milling machine,grinder,etc. Each of our machine undergoes a multi-step superb machining process and rigorous measurement and assembly. Every producing step of the machine undergo quality inspection and mutual inspection,The company has complete testing methods and advanced inspection techniques.All the machines should be 100% qualified before sales.

The company's processing equipment includes large-scale CNC floor-standing boring and milling machines, CNC gantry machining centers and other advanced equipment. Our company has passed the ISO,CE,SGS and other certification,has a number of product innovation patents and honorary certificates. Our main products include manual lathe,cnc lathe,saw machines,machine tool,Drill machine, Milling machine,Machining Center,CNC milling machine,grinder,etc. Each of our machine undergoes a multi-step superb machining process and rigorous measurement and assembly. Every producing step of the machine undergo quality inspection and mutual inspection,The company has complete testing methods and advanced inspection techniques.All the machines should be 100% qualified before sales.

Our customers come from all over the world.

QUALITY CONTROL

We have been manufacturing hydraulic press machine and guillotine machines for almost two decades, which has given us the expertise and confidence to tackle future challenges. Our success is attributed to our commitment to high-quality standards and our highly trained and knowledgeable team. By continually improving our internal processes, we have been able to produce machines of exceptional quality that have positioned Nadun as a leader in the industry. Our commitment to excellence is evident in the quality of our machines, which serves as a guarantee to our customers.1.Can you provide me with the relevant documentation?

Yes, we can provide you with most documentation including Certificates of Analysis/Conformance, insurance, origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 30 days. For mass production, the lead time is 30-60 days after receiving the deposit payment. Our lead times become effective when we have received your deposit and have your final approval for your products. If our lead times do not work with your deadline, please discuss your requirements with your sales representative. In most cases, we are able to accommodate your needs.

3.What payment methods do you accept?

We accept payment via bank transfer, Western Union, or PayPal. The payment terms are typically a 30% deposit in advance, with the remaining 70% balance due against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. Whether in warranty or not, it is our company culture to address and resolve all customer issues to everyone's satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high-quality export packaging to ensure the safe and secure delivery of our products. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature-sensitive items. However, specialist packaging or non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the method you choose to receive your goods. Express delivery is usually the quickest but also the most expensive option. Seafreight is the best solution for large amounts. We can provide you with detailed freight rates once we know the details of the amount, weight, and shipping method. Please contact us for further information.