- Overview

- Product Description

- Product images

- Main feature:

- Detailed Photos

- Product Parameters

- Application Areas

- Company Profile

Basic Info.

Packaging & Delivery

Product Description

This series is a general-purpose hydraulic press, also known

as universal hydraulic press. This hydraulic press is suitable

for stretching and punching (optional punching buffer),

bending, flanging and cold extrusion of metallic materials.

It is also suitable for pressing of powdered and abrasive

products, as well as pressing and molding of plastic products

and insulating materials. The product is available in a variety

of models for a wide range of uses, and we can also support

model customization, which can meet your different work

requirements.

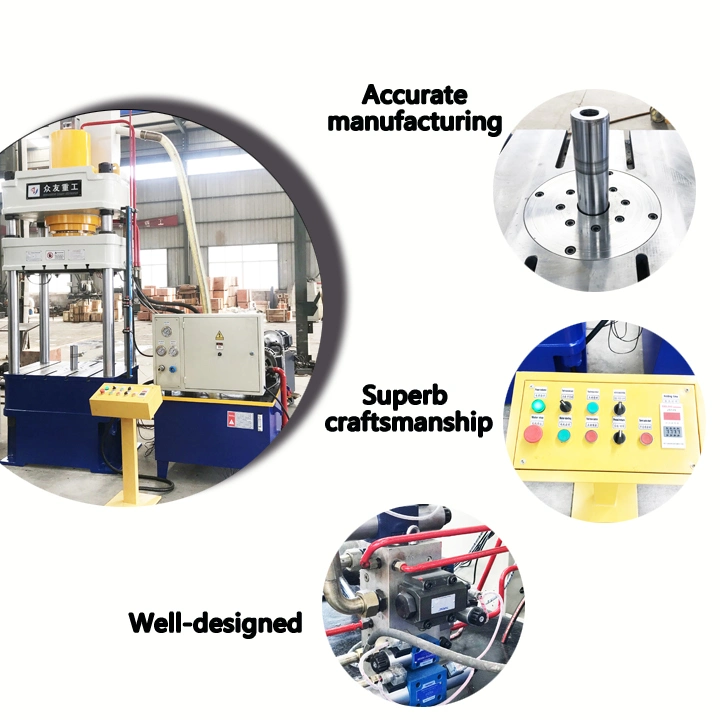

1.Structure: consists of upper beam, sliding block, table, column, main cylinder, hydraulic system and electrical system.This column is made of 45 forged steel with a surface hardness of hrc38-42.The main cylinder seal USES imported material to ensure the seal is reliable.

A hundred ton, 300 ton, 500 ton, four column hydraulic press.

2.Hydraulic system: the hydraulic system device is installed on the right side of the press, with the shell integrated system, flexible operation, reliable work, good sealing performance.The hydraulic pump includes an oil tank, a high pressure pump, motor, cartridge valve and other components.

100 ton, 300 ton, 500 ton, four column hydraulic press.

3.Electrical control system: independent gas cabinet and central control panel.

100 ton, 300 ton, 500 ton, four column hydraulic press.

4.Operation: two working modes, such as inches and semi-automatic batting.

1. The machine has independent power mechanism and electrical system. It adopts centralized control of buttons, which can realize three working modes: adjustment, manual and semi-automatic.

2. The working pressure and pressing speed of the machine, the stroke and range of no-load fast-down and deceleration, all according to the process.

3. It can be equipped with three processes: ejector process and stretch process. Each process is for constant pressure and constant process. The constant pressure molding process has Ejection delay and automatic return trip.

4. We selected high quality accessories, long service life, reduced cost, high level of protective insulation, safe and reliable operation.

| Parameters | Unit | YQ32-200B | YQ32-315A | YQ32-315B | YQ32-400 | YQ32-630 |

| Nominal force | KN | 2000 | 3150 | 3150 | 4000 | 6300 |

| Max.pressure of hydraulic system | Mpa | 25 | 25 | 25 | 25 | 25 |

| Slider Max.Opening height | mm | 900 | 1250 | 1000 | 1250 | 1500 |

| Slider Effective Stroke | mm | 600 | 800 | 600 | 800 | 900 |

| Effective worktable size | mm | 800*800 | 1260*1160 | 800*800 | 1260*1160 | 1600*1600 |

| Nominal force of upper ejection cylinder | KN | 400 | 630 | 630 | 630 | 1000 |

| Stroke of upper ejection cylinder | mm | 220 | 300 | 300 | 300 | 300 |

| Slider descending speed | mm/s | 100 | 120 | 120 | 120 | 150 |

Slider pressing speed | mm/s | 5-10 | 8-15 | 8-15 | 8-15 | 10-22 |

Slider return speed | mm/s | 90 | 90 | 90 | 90 | 120 |

All Parameters can be customized according to the products you make.

The hydraulic press machine is mainly used for the process of stretching, bending and forming of thin plates, and can also be used for plastic pressing, cold extrusion bending, forming correction and press fitting.

Particularly applied in the following industries:

1. Auto parts: body cover, brake pads, fuel tank, chassis, bridge, bumper;

2. Household appliances: washing machines, rice cookers, televisions, refrigerators, air conditioners, etc.;

3. Kitchen utensils: washing tanks, pots, stainless steel cutlery, and other various containers;

4. Others: tractors, motorcycles, aviation, aerospace, water tanks.

Product Catalog

| Product classification | Product Name | ||

| A | Four column hydraulic press machine | A1 | Coin hydraulic press making machine |

| A2 | melamine dinner set hydraulic press making machine | ||

| A3 | Stainless steel sink hydraulic press machine | ||

| A4 | Kitchen cookware hydraulic press machine | ||

| A5 | Wheel Barrow hydraulic press machine | ||

| A6 | Animal salt block hydraulic press machine | ||

| A7 | Door skin hydraulic press machine | ||

| A8 | Powder forming hydraulic press machine | ||

| A9 | animal mineral block hydraulic press machine making machine | ||

| A10 | hydraulic press machine for seedling clod | ||

| A11 | hydraulic press machine for tablet | ||

| A12 | Auto parts hydraulic press machine. | ||

| A13 | .... | ||

| B | C frame hydraulic press machine | B1 | Door embossing hydraulic press machine. |

| B22 | Bearing press-fitting hydraulic press machine. | ||

| B3 | .... | ||

| C | Frame type/frame hydraulic press machine | C1 | Door skin hydraulic press machine |

| C2 | Solid tire hydraulic press machine | ||

| C3 | Forklift Solid Tyre Press Machine | ||

| C4 | ... | ||

| D | Customizing machine | D1 | ... |

Zhongyou Heavy Industry Machinery Equipment Co., Ltd. is one of the professional manufacturers of hydraulic deep-drawing machines, with advanced equipments, which can produce all kinds of deep-drawing machines and car care equipments. Our products include multifunctional hydraulic press, three-beam four-column deep drawing machine, cattle and sheep licking brick machine, powder molding machine, single-arm hydraulic press, gantry hydraulic press and so on. Located in Tengzhou City, Shandong Province, China, the company relies on first-class production technology, professional production level and perfect service to stand out from many hydraulic press manufacturers, and is widely praised by domestic and foreign customers.