Basic Info.

Model NO.

HZ-230926-03

Processing

Laser Cutting/Bending/Welding/Shearing

Size

Custom

Service

OEM/ODM

Quality Control

100% Inspect Before Shipment

Packing Detail

Standard Export Packing

Delivery Lead Time

7-25 Working Days(as Per Your Order Qty)

Factory Location

Shenzhen, China

Export Markets

Global

Trade Terms

EXW,Fob

Transport Package

Plastic Film+Harden Carton Box+Plywood Case

Specification

RoHS

Trademark

HZCX

Origin

Shenzhen, China

HS Code

7616999000

Production Capacity

200000/Year

Product Description

Master Custom Stainless Steel Fabrication factory--Focus on precision Stainless steel sheet Metal Fabrication tray, hopper, Box, bracket, panel, and hopper, the surface can be a natural color without a scratch, mirror polish finish, or brush finish.

Our Advantages

Company Information

Shenzhen HONGZHOU Technology Co. LTD was founded in 2005 years with ISO9001 certification.

Mainly specializes in sheet metal fabrication and customized service, and has more than 10 years' experience in this field.

Our products include machine enclosures, equipment cabinets, control panels, etc.

The biggest advantage of my company is customized service, we can produce precision products according to your requests.

You can enjoy the most competitive price because we are the direct manufacturer and supplier.

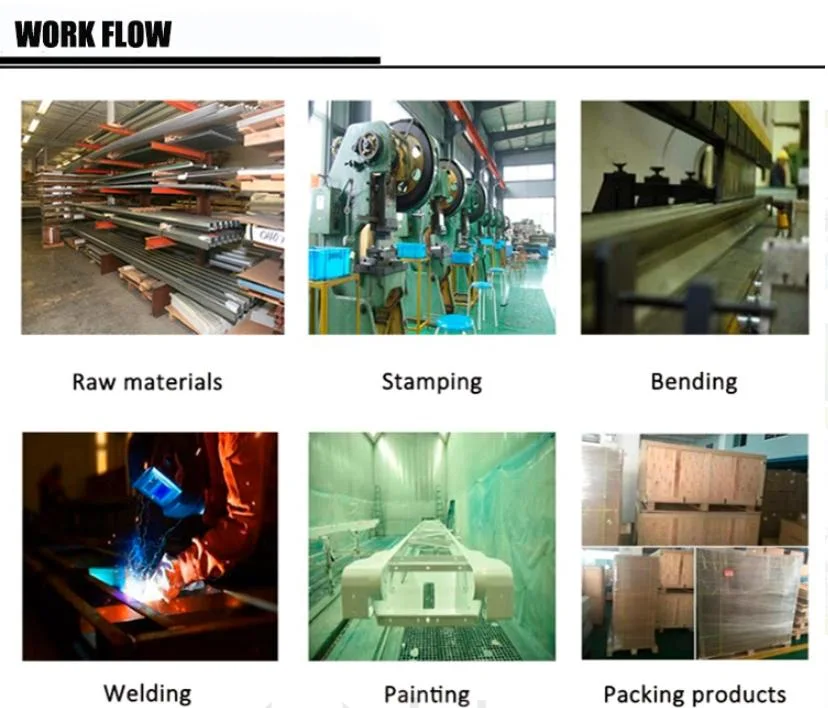

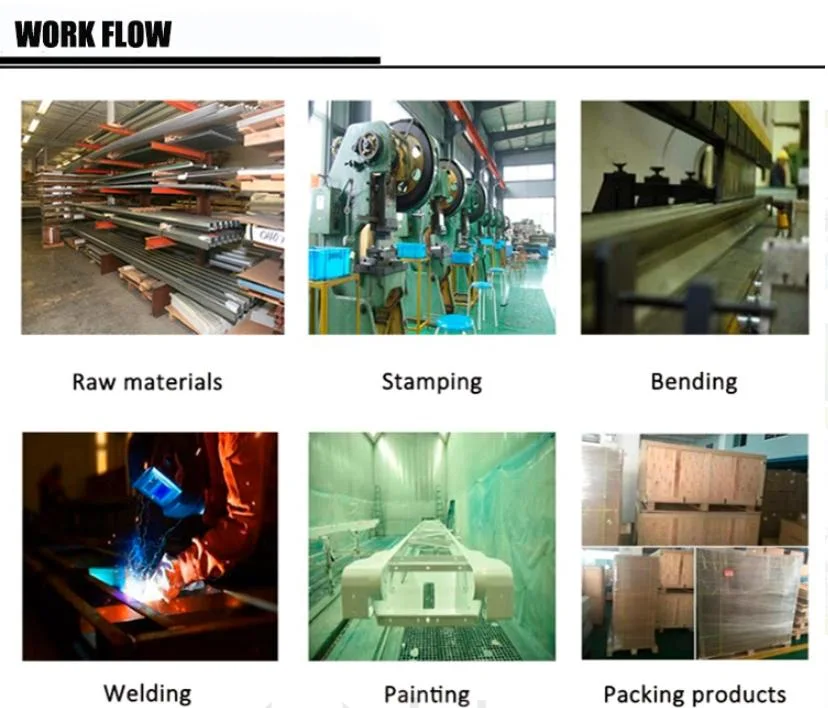

Sheet Metal Fabrication Capability

| Manufacturing Process | Laser cutting, CNC punching, stamping, bending, punching, threading, welding, polishing, tapping, riveting, assembly. |

| Material | Stainless steel, carbon steel, copper, aluminum, brass, iron, and bronze (according to customer's requirements) |

| Surface Treatment | Galvanized(zinc-plated, nickel-plated,chrome-plated, silver-plated), powder coating, polishing(mirror polishing, electrolytic polishing), brushing, sandblasting, chemical etching, passivation treatment, etc. |

| Tolerance | +/-0.01mm |

| Package | Plastic film+harden carton box+plywood case |

| Application | Auto parts, food machinery, medical testing and equipment, electronic products, electric appliances, power switches, miniature switches, A/V equipment. |

| Quality Control | Conducted by ISO9001:2008 |

| Drawing File Format | Solidworks, Pro/E, Auto CAD, PDF, UG |

| Features | 1.Customized design 2. Small orders allowed 3. Sample product available 4. Competitive price due to factory direct supply |

| Inspection | IQC, IPQC, FQC, OQA |

Our Advantages

1. Quick Response and quick action, your inquiry will be replied to in 24 hours.

2. Competitive price directly from in housing plant.

3. High quality due to first-hand control in the factory.

4. OEM/ODM: custom fabrication according to your drawings or samples.

5. Flexibility: small orders are acceptable for quick delivery and help you reduce the stock cost.

6. Quick delivery and overseas Kanban warehouse service. We have overseas warehouses located in Hong Kong and London to support overseas clients.