- Overview

- Product Description

- The configuration we provide

- Product Parameters

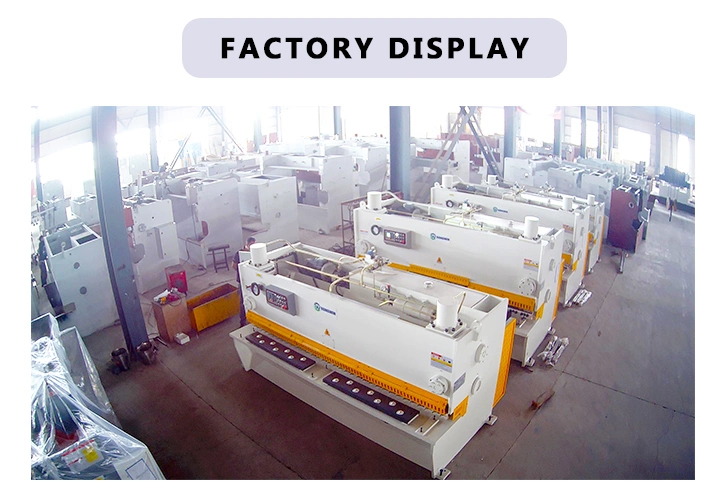

- Company Profile

- Certifications

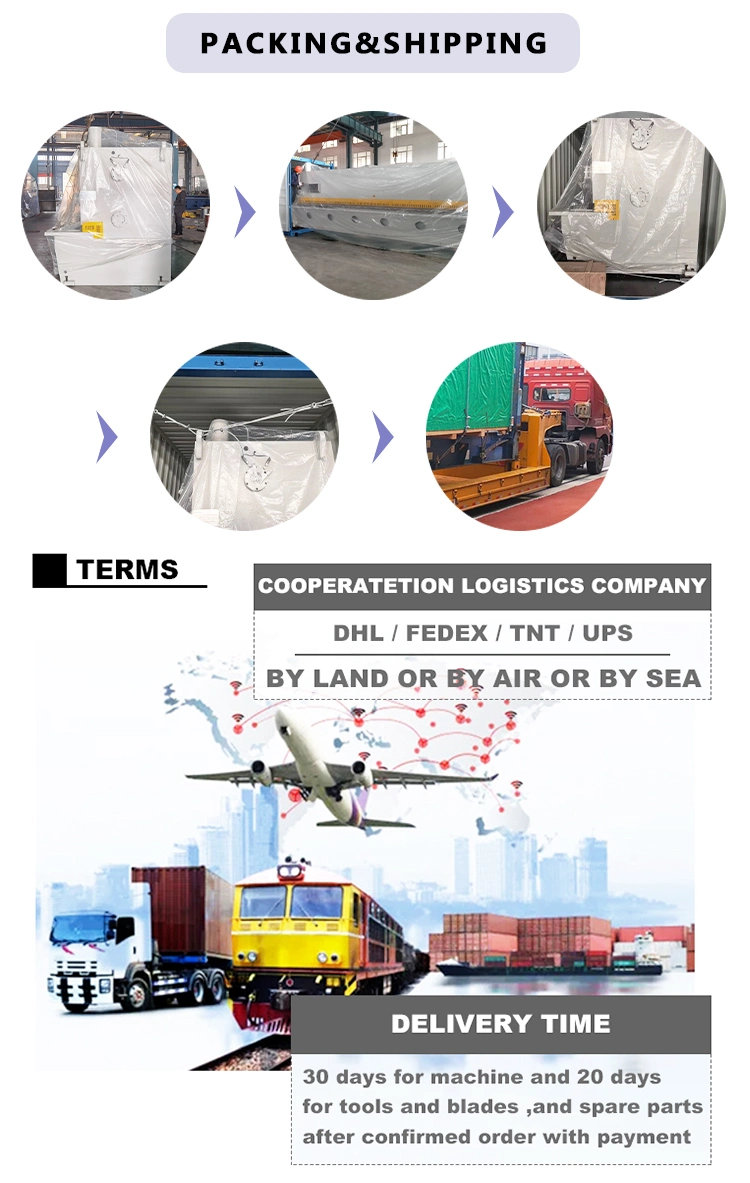

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

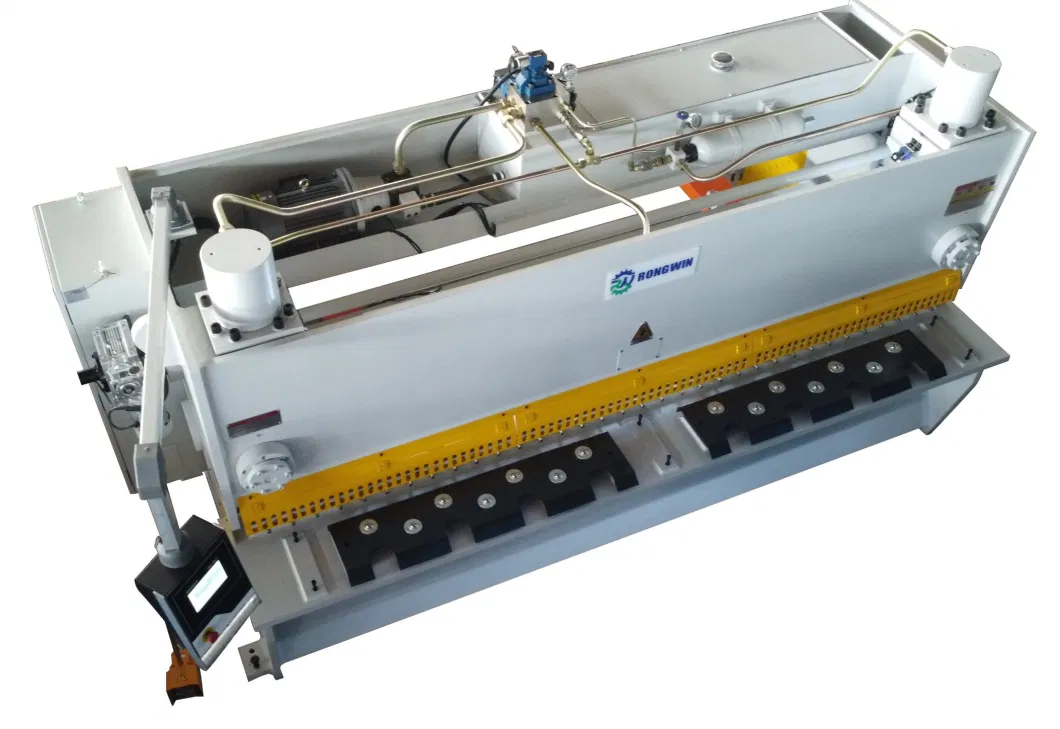

Qc11y Hydraulic Mechanical Sheet Metal Shearing Machine for sale

1.The frame is steel welded structure, have sufficient strength and rigidity, eliminate internal stress and high frequency vibration, to ensure the overall accuracy of the fuselage. Has a good rigidity, two cylinders fixed on the left and right columns (wallboard).

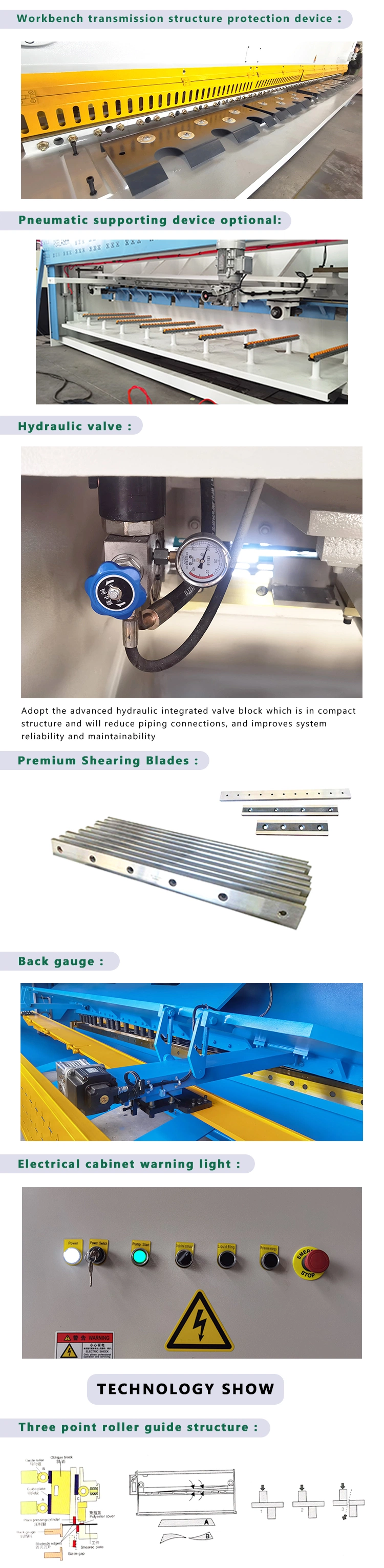

2.Shear blades use 6CrW2Si material , heat treatment ,high quality materials ,can cutting stainless steel ,top blade with four cutting edges ,bottom blade with four cutting edges.

3.Worktable use ball, convenient feed materials, and ensure that the work piece is not scratched at run time.

Main Configuration :

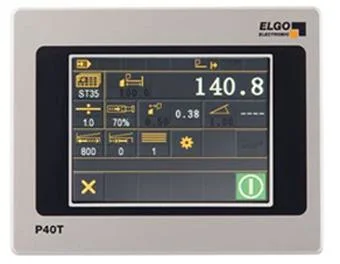

| NC Control system | E21S/P40T ELGO/DAC310/DAC360 |

| Main Electric Components | Schneider Electrical from French |

| Main Motor | Siemens from Germany Brand |

| RAM Drive | Energy-saving servo drive from Taiwan delta |

| Hydraulic System | Bosch-Rexroth form Germany |

| Sealing Element | anti-corrosion |

| Tubing connector | EMB form Germany |

| Ball screw/ Polished rod | HIWIN from TaiWan |

| Foot Switch Electric Components | Schneider Electrical from French |

| Safety light certain | (Optional) |

Selectable control system :

1.Backstop control;

2.Control of ordinary motor or frequency converter; Intelligent 3.positioning;

4.Dual-channel programmable digital output;

5.Artifacts count40 program stores,each program 25 steps;

6.Unilateral positioning Concession function;

7.Parameter 1 step backup and restore: Metric system

1.Panel based housing

2.Bright LCD screen

3.Back / front gauge control

4.Retract function

5.Cutting angle and gap control

6.Stroke length limitation

7.Manual movement of all axes

8.Force control

9.Sheet thickness measurement

10.Return to Sender function

11.Second and third servo axis

12.Sheet support

1.Panel based housing

2.Bright LCD screen

3.Back gauge control

4.Retract function

5.Cutting angle or gap control

6.Stroke length limitation

7.Manual movement of axes

8.Stock count

1.16 free programmable digital in-/outputs

2.Angle control / gap control / backgauge

3.Cut length and cut offset calculation by angle measurement system or time

4.Cut automation

1.Simple page, clear and eye-catching icons, easy to operate. 2.Automatically calculate various data required for shearing according to material properties.

3.Supports more than 10 languages.

4.Automatically adjust the blade gap.

Three roller guide structure is adopted, and the front prepressure guide rail is used to keep the tool frame sticking to the upper guide rail and the

Three roller guide structure is adopted, and the front prepressure guide rail is used to keep the tool frame sticking to the upper guide rail and the

lower guide rail.

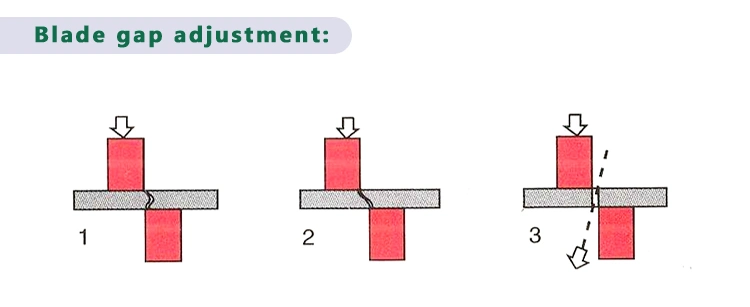

In the shear, the clearance of the blade can be adjusted according to the demand of different sheet materials to achieve better shear quality. The right blade clearance will receive satisfactory shear effect. The machine tool is equipped with a quick blade clearance adjusting mechanism, which can meet the needs of different thickness of plate and material, and can be adjusted by rotating the hand wheel.

The right blade clearance will receive satisfactory shear effect. The machine tool is equipped with a quick blade clearance adjusting mechanism, which can meet the needs of different thickness of plate and material, and can be adjusted by rotating the hand wheel.

| Type | Cutting thickness (mm) | Cutting width (mm) | Travel times (times/min) | Bumper distance (mm) | Cutting angel (º) | Throat depth (mm) | Power (kw) | Dimension LxWxH (mm) |

| 4x2500 | 4 | 2500 | >=18 | 600 | 0.5-2 | 100 | 5.5 | 3130x1500x2070 |

| 4x3200 | 4 | 3200 | >=16 | 600 | 0.5-2 | 100 | 7.5 | 3830x1500x2070 |

| 4x4000 | 4 | 4000 | >=12 | 600 | 0.5-2 | 100 | 7.5 | 4630x1500x2070 |

| 6x2500 | 6 | 2500 | >=15 | 600 | 0.5-2 | 100 | 7.5 | 3150x1600x2170 |

| 6x3200 | 6 | 3200 | >=13 | 600 | 0.5-2 | 100 | 7.5 | 3850x1600x2170 |

| 6x4000 | 6 | 4000 | >=10 | 600 | 0.5-2 | 100 | 7.5 | 4650x1600x2170 |

| 6x5000 | 6 | 5000 | >=8 | 600 | 0.5-2.5 | 100 | 11 | 5650x1600x2270 |

| 6x6000 | 6 | 6000 | >=6 | 600 | 0.5-2.5 | 100 | 11 | 6650x1610x2380 |

| 8x2500 | 8 | 2500 | >=14 | 600 | 0.5-2 | 100 | 11 | 2170x1600x2170 |

| 8x3200 | 8 | 3200 | >=12 | 600 | 0.5-2 | 100 | 11 | 3870x1600x2170 |

| 8x4000 | 8 | 4000 | >=10 | 600 | 0.5-2 | 100 | 11 | 4670x1600x2170 |

| 8x5000 | 8 | 5000 | >=8 | 600 | 0.5-2.5 | 100 | 11 | 5670x1600x2270 |

| 8x6000 | 8 | 6000 | >=6 | 600 | 0.5-2.5 | 100 | 15 | 6670x1610x2380 |

| 10x2500 | 10 | 2500 | >=12 | 600 | 0.5-2 | 100 | 11 | 3190x1600x2170 |

| 10x3200 | 10 | 3200 | >=10 | 600 | 0.5-2 | 100 | 11 | 3890x1600x2170 |

| 10x4000 | 10 | 4000 | >=8 | 600 | 0.5-2 | 100 | 11 | 4690x1600x2170 |

| 10x5000 | 10 | 5000 | >=6 | 600 | 0.5-2.5 | 100 | 11 | 5690x1600x2270 |

| 10x6000 | 10 | 6000 | >=4 | 600 | 0.5-2.5 | 100 | 15 | 6690x1610x2380 |

| 12x2500 | 12 | 2500 | >=10 | 800 | 0.5-2.5 | 100 | 15 | 3270x1850x2315 |

| 12x3200 | 12 | 3200 | >=8 | 800 | 0.5-2.5 | 100 | 15 | 3970x1850x2315 |

| 12x4000 | 12 | 4000 | >=6 | 800 | 0.5-2.5 | 100 | 18.5 | 4770x1850x2315 |

| 12x5000 | 12 | 5000 | >=6 | 800 | 0.5-2.5 | 100 | 18.5 | 5770x1950x2515 |

| 12x6000 | 12 | 6000 | >=4 | 800 | 0.5-2.5 | 100 | 22 | 6770x2100x2750 |

| 16x2500 | 16 | 2500 | >=8 | 800 | 0.5-2.5 | 100 | 18.5 | 3270x1850x2315 |

| 16x3200 | 16 | 3200 | >=7 | 800 | 0.5-2.5 | 100 | 18.5 | 3970x1850x2315 |

| 16x4000 | 16 | 4000 | >=6 | 800 | 0.5-2.5 | 100 | 22 | 4770x1850x2315 |

| 16x5000 | 16 | 5000 | >=5 | 800 | 0.5-2.5 | 100 | 22 | 5770x1950x2515 |

| 16x6000 | 16 | 6000 | >=4 | 800 | 0.5-2.5 | 100 | 30 | 6770x2100x2750 |

| 20x2500 | 20 | 2500 | >=7 | 800 | 0.5-2.5 | 100 | 30 | 3370x2015x2575 |

| 20x3200 | 20 | 3200 | >=6 | 800 | 0.5-2.5 | 100 | 30 | 4070x2015x2575 |

| 20x4000 | 20 | 4000 | >=5 | 800 | 0.5-2.5 | 100 | 37 | 4870x2015x2675 |

| 20x5000 | 20 | 5000 | >=4 | 800 | 0.5-2.5 | 100 | 37 | 5870x2115x2875 |

| 20x6000 | 20 | 6000 | >=3 | 800 | 0.5-2.5 | 100 | 45 | 6870x2300x3200 |

| 25x2500 | 25 | 2500 | >=6 | 1000 | 0.5-3 | 120 | 37 | 3390x2200x2700 |

| 25x3200 | 25 | 3200 | >=5 | 1000 | 0.5-3 | 120 | 37 | 4090x2200x2700 |

| 25x4000 | 25 | 4000 | >=4 | 1000 | 0.5-3 | 120 | 45 | 4890x2350x3000 |

| 32x2500 | 32 | 2500 | >=5 | 1000 | 0.5-3 | 120 | 45 | 3490x2440x2915 |

| 32x3200 | 32 | 3200 | >=4 | 1000 | 0.5-3 | 120 | 45 | 4190x2440x3015 |

| 32x4000 | 32 | 4000 | >=3 | 1000 | 0.5-3 | 120 | 55 | 5100x2500x3315 |

| 40x2500 | 40 | 2500 | >=4 | 1000 | 0.5-3 | 120 | 75 | 3530x2500x3300 |

| 40x3200 | 40 | 3200 | >=3 | 1000 | 0.5-3 | 120 | 75 | 4230x2500x3500 |

Attention: The above date is juso for gour reference, if there is ang disaccord please refer to actual adate.

Founded in 2017 years, Nanjing RONGWIN Machinery Technology Co., Ltd is focus on press brake manufacturing and a professional one-stop smart custom metal solution service supplier.We are committed to building a strong Chinese metal working machinery and spare parts supply Chain System.

We have a dream "Let China's one-stop smart custom metal solution serve the world " and "We want to become a respected Chinese press brake manufacture, live 100 years " That's why we're always tring to keep our users satisifed.

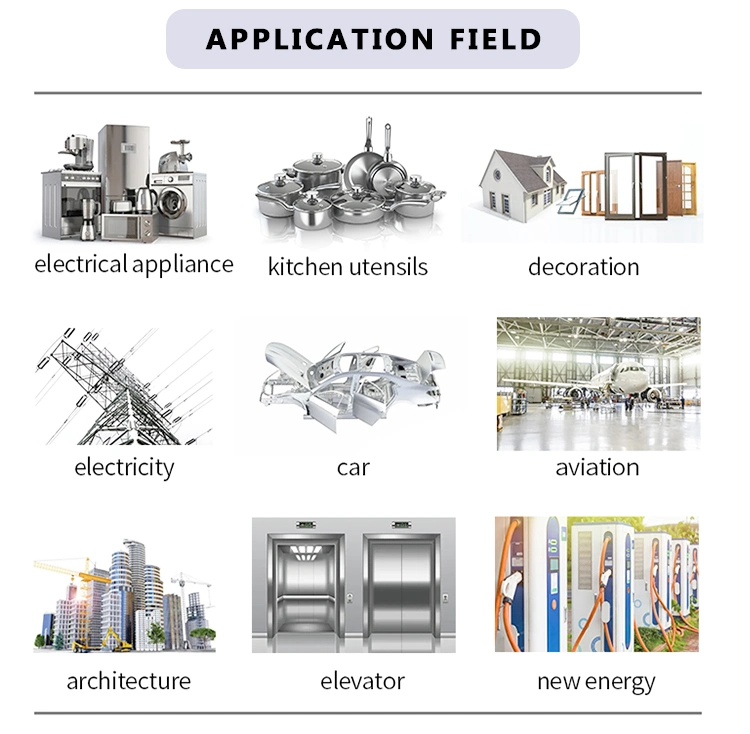

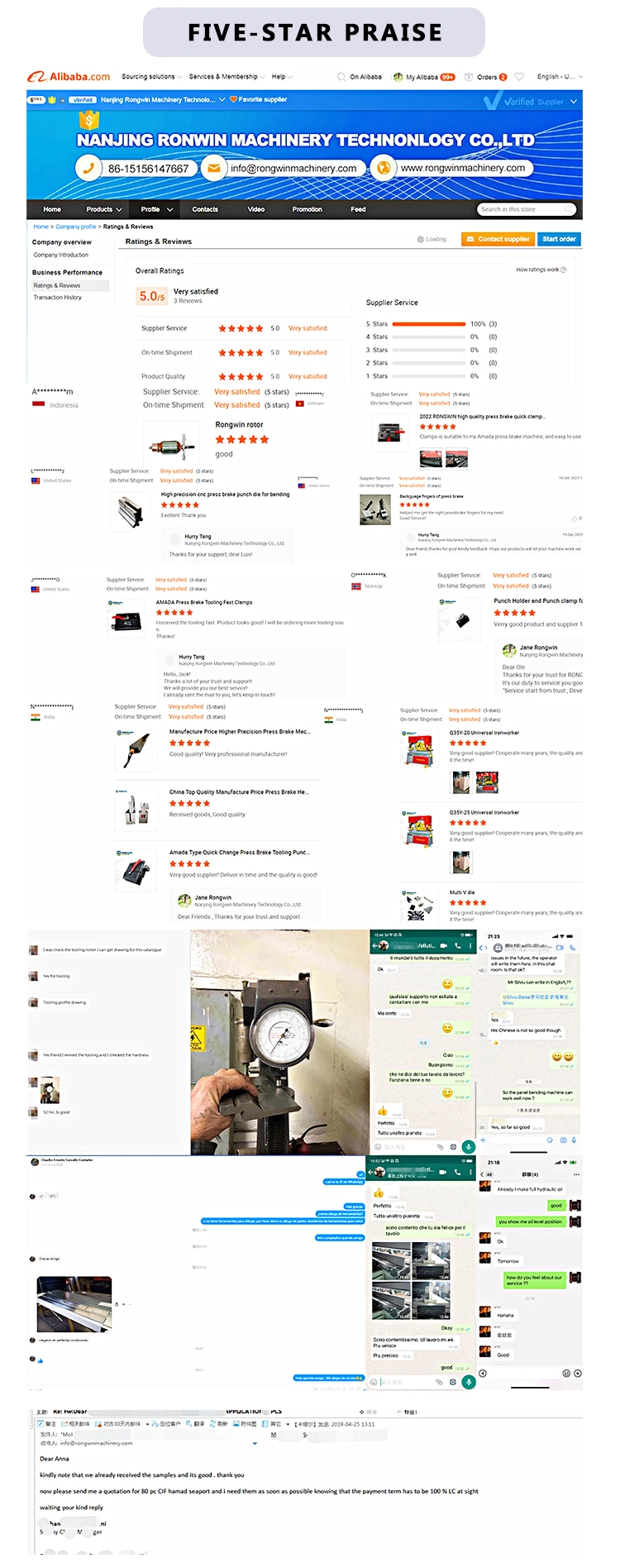

we are specialized at metal working machinery and spar parts, like press brake, panel bender, fiber laser cutting machine, shearing machine, rolling machine, V grooving machine, hydraulic press, power press, ironworker, notching machine, tube cutting machine, tube bending machine, HVAC Dust Machine, punching die, blades, kinds of toolings, etc. We can give customer all the aspect solutions for the metal industry fabrication machinery. We can guide customers for choosing their metal processing equipment so that customer can get the most cost-effective solution by our guide. Meanwhile we also can do O E M & O D M service. We have professional engineer support, high efficiency sales team and competitive price , we design our machine in a top class level which makes our machine in a good looking appearance , due to the good after sale service and reliable quality, we have sold to many foreign customers, they like our machines, they usually buy from us not only one time, now we already sold to more than 70 countries, including Europe, South America like Brazil, U S A, Canada, Russia, Vietnam, Pakistan, Australia, New Zealand, Africa, Middle East country etc. After several years' development, We already applied some patent, and also got CE certificate and SGS for Press Brake, Laser Cutting machine, Panel Bender,V grooving machine etc, we will grow up together with our customer's support, we believe that our company will have a bright future.

Please trust ROGNWIN .We are always trying to make you satisifed.

1.Are you the manufacturer ? Can we visit your factory ?

Yes ,of course you can ,We have our own technical team for products design, welcome to visit our factory and check our machines quality,we will answer your requirements on time.

2.What is your main product ?

Our main products are plate cutting ,bending,straightening machines, panel bender, fiber laser cutting machines, hydraulic machines, V grooving machines, etc. Our main exporting market is South America,Europe,Middle East and Africa.

3.What are the advantages of RONGWIN machines, how can i believe the quality ?

Our factory has the advanced CNC processing equipment to ensure accuracy, and we have professional technical personnel to inspect and ensure that every machine must meet the standard before leaving the factory.

4.Can we become the sales distributor for RONGWIN ?

Yes ,so far we are looking for sales agents from different countries ,if the cooperation is successful ,as an agent ,you would get more preferential price based on sales quantities.

5.What is your payment term ?

T/T ,L/C,Western Union ,Alibaba Secure Payment etc.

6.How can you guarantee the after-sales service ?

First of all, we will provide relevant technical documents and guide you to operate online.Then, if engineers must be arranged, we can also arrange engineers to go abroad for training and debugging.

7.Can your factory provide OEM service ?

Based on sales quantities, we would be very happy to do so.