- Overview

- Product Description

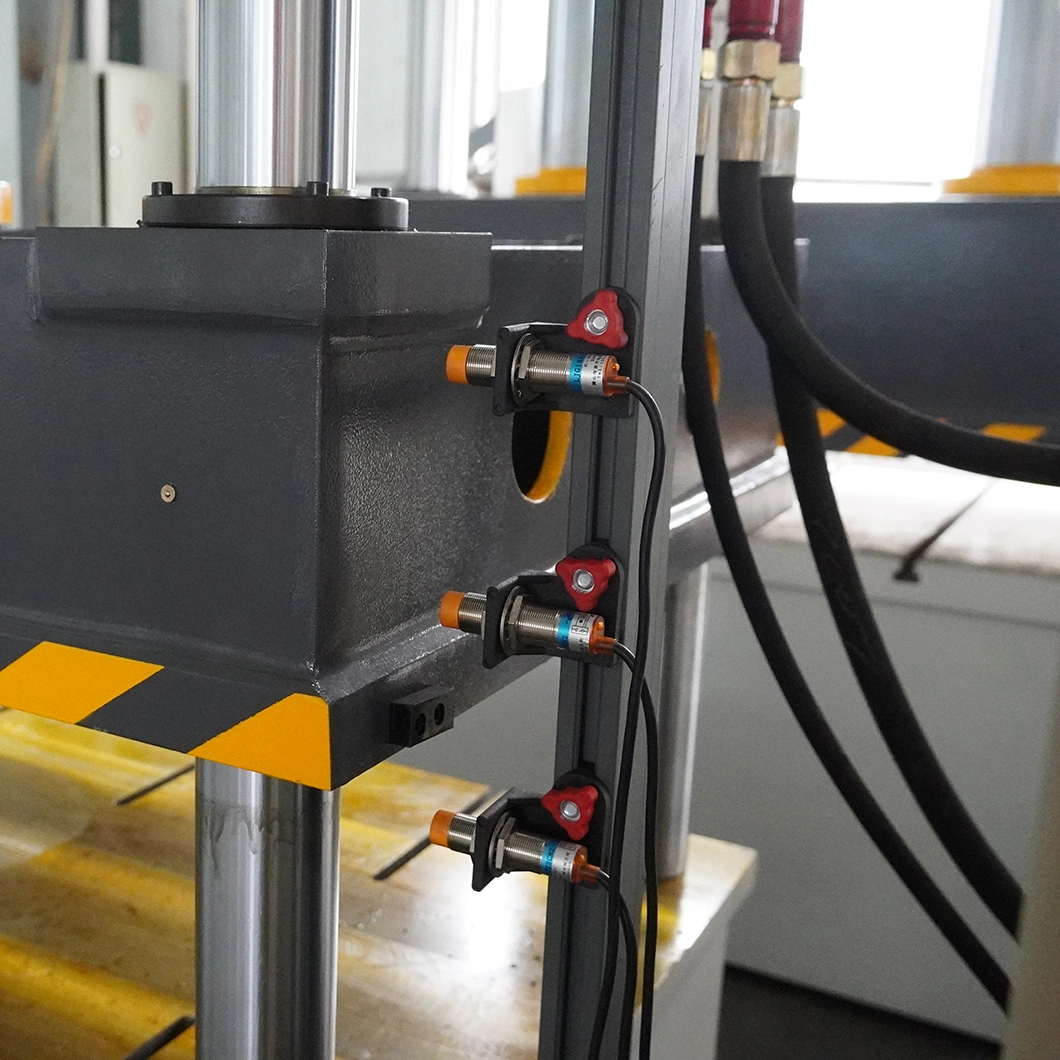

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Company Profile

- Customer Visit

- FAQ

Basic Info.

Packaging & Delivery

Product Description

This hydraulic press machine is specifically designed for pressing products like the one shown in the picture above. With its precise and efficient hydraulic system, high-strength steel frame, and advanced safety features, it is the perfect solution for pressing operations in industries such as automobile manufacturing, home appliances, and hardware processing. Invest in this reliable and versatile machine to take your pressing capabilities to the next level.

T-shaped groove

For ease of mold installation in future use, the hydraulic pad has been engraved with a convenient T-shaped groove. This simplifies the process and makes it more efficient.

Adjustable Pressure Pump Station provides precise pressure control using pressure sensors and electronic controls, making it useful in applications where pressure requirements vary. It also offers greater flexibility and control over the pumping process, optimizing energy consumption and reducing fluid loss.

Siemens Electrical Systems are designed to last for a long time and offer a high level of safety assurance. They are engineered to be extremely durable and reliable, ensuring the safety of the users.

1. Easy mobility to desired location for convenient work.

2. Equipped with multiple storage drawers and shelves for tools and materials.

3. Customizable and adjustable to fit various work requirements.

4. Improves work efficiency, saving time and energy.

| SPECIFICATION | UNIT | YQ32-63T | YQ32-100TA | YQ32-100TB | YQ32-200TA | YQ32-200TB |

| Nominal force | KN | 630 | 1000 | 1000 | 2000 | 2000 |

| Max.System pressure | Mpa | 25 | 25 | 25 | 25 | 25 |

| Max.Open height | mm | 700 | 800 | 900 | 1200 | 900 |

| Max.Stroke of slider | mm | 400 | 500 | 600 | 700 | 600 |

| Effective table size | mm | 610x500 | 630x550 | 750x700 | 1000x1000 | 800x800 |

| Down speed | mm/s | 180 | 120 | 120 | 100 | 100 |

| Pressing speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 |

| Return speed | mm/s | 100 | 120 | 120 | 70 | 70 |

| Ejection cylinder force | KN | 100 | 200 | 200 | 400 | 400 |

| Stroke of ejectioncylinder | mm | 160 | 200 | 200 | 220 | 220 |

| SPECIFICATION | UNIT | YQ32-315TA | YQ32-315TB | YQ32-400T | YQ32-500T | YQ32-630T |

| Nominal force | KN | 3150 | 3150 | 4000 | 5000 | 6300 |

| Max.System pressure | Mpa | 25 | 25 | 25 | 25 | 25 |

| Max.Open heigh | mm | 1250 | 1000 | 1250 | 1500 | 1500 |

| Max.Stroke of slider | mm | 800 | 600 | 800 | 900 | 900 |

| Effective table size | mm | 1260x1160 | 800x800 | 1260x1160 | 1400x1400 | 1600x1600 |

| Down speed | mm/s | 100 | 100 | 100 | 100 | 80 |

| Pressings pee | mm/s | 7-11.5 | 7-11.5 | 5-9 | 8-15 | 6-12 |

| Return speed | mm/s | 60 | 60 | 55 | 70 | 60 |

| Ejection cylinder force | KN | 630 | 630 | 630 | 1000 | 1000 |

| Stroke of ejectioncylinder | mm | 300 | 300 | 300 | 300 | 300 |

| SPECIFICATION | UNIT | YQ32-800T | YQ32-1000T | YQ32-1250T | YQ32-1600T | |

| Nominal force | KN | 8000 | 10000 | 12500 | 16000 | |

| Max.System pressure | Mpa | 25 | 25 | 25 | 25 | |

| Max.Open height | mm | 1800 | 1600 | 1600 | 1800 | |

| Max.Stroke of slider | mm | 1000 | 900 | 900 | 1000 | |

| Effective table size | mm | 1500x1500 | 1500x1500 | 1800x1600 | 1600x1600 | |

| Down speed | mm/s | 80 | 80 | 80 | 80 | |

| Pressing speed | mm/s | 8-17 | 6-13 | 7-15 | 8-17 | |

| Return speed | mm/s | 70 | 70 | 70 | 70 | |

| Ejection cylinder force | KN | 1000 | 1000 | 1000 | 1600 | |

| Stroke of eject on cylinder | mm | 350 | 350 | 350 | 350 |

Why choose us?

Our company boasts a range of advanced processing equipment, including large-scale CNC floor-standing boring and milling machines and CNC gantry machining centers. We have obtained ISO, CE, SGS, and other certifications, in addition to several product innovation patents and honorary certificates.

Our product line comprises a vast array of machines, such as manual lathes, CNC lathes, saw machines, machine tools, drill machines, milling machines, machining centers, CNC milling machines, grinders, and more. Each machine undergoes a meticulous multi-step machining process and strict measurement and assembly procedures, with quality inspections and mutual inspections conducted throughout each production step.

We employ advanced inspection techniques and have complete testing methods to ensure that all machines are 100% qualified before being sold. At our company, we are committed to delivering high-quality machines that meet the most demanding specifications.

Our customers come from all around the world.

Q1: What is your after-sales service policy?

A: We offer a one-year guarantee and will provide spare parts if any problems arise due to our manufacturing. You can contact us directly with any issues.

Q2: Can I visit your factory before placing an order?

A: Absolutely, we welcome you to inspect our factory. Our factory is located at No. 219 Xingye Road, Tengzhou City, Shandong Province. We can arrange to pick you up from Tengzhou station and offer hotel booking services.

Q3: Are you a factory or trading company?

A: We are a manufacturer with our own factory, and approximately 50-60% of our production is exported.

Q4: How can I trust your company?

A: We have a professional design team that can provide suitable suggestions and the best prices for our equipment. We have been assessed by third-party organizations and have obtained national patents and CE, ISO certifications for all our equipment. You are welcome to inspect our factory at any time, and we also offer Trade Assurance.