Basic Info.

Model NO.

JPW80BL

Power

45kw

Feed Opening

1800*1100mm

Bale Size

1100*1200*300-1300mm

Bale Weight

About 1000-1200kg

Suitable Materials

Plastic/Pet Bottles/Cans

Press

Straw, Cardboard, Corrugated Paper

Transport Package

Seaworthy Packing

Specification

150ton pressure

Trademark

JEWEL

Origin

China

HS Code

842240

Production Capacity

12000sets Per Year

Product Description

Manufacturers Packing Waste Recycling Horizontal Hydraulic Automatic Foam Compactor Baler Machine for Plastic Films/Jute Bag/Pet Bottles/Carton/Corrugated Paper/Textiles/Corrugated Paper/Textiles/MSW Waste/Community Waste/Solid Waste/ PET Bottle/Foam/ PET Scrap/Plastic Bottle/Domestic Waste/Waste Plastic/Waste Paper/Waste Plastics/Plastic Film

| Model | JPW80BL | JPW100BL | JPW120BL | JPW150BL |

| Hydraulic power | 80T | 100Ton | 120Ton | 150Ton |

| Bale size(L*W*H)mm | 1000*800*(300-1100) | 1100*800*(300-1200) | 1100*1100*(300-1200) | 1100*1100*(300-1200) |

| Feed opening size(L*W)mm | 1200*1100 | 1400*1100 | 1600*1100 | 1600*1100 |

| Bale Weight | 350-500kg | 400-650kg | 600-800kg | 700-900kg |

| Bale line | 4line | 4line | 5line | 5line |

| Out-bale way | One-off bag out | One-off bag out | One-off bag out | One-off bag out |

| Power | 22KW/30HP | 30KW/40HP | 37KW/50HP | 45KW/60HP |

| Machine size (mm) | 6750*1770*2000 | 7500*1650*2200 | 7500*1750*2200 | 8800*1850*2550 |

Specifications

* It is closed type hydraulic baler with lifting open-end door, no need to shift balers timely after package, it can push bags continuously.

* It has high strength output door, hydraulic automatic open-end door, convenient operation and safety.

* It configures with PLC program and electric button control, operated simply and equipped with automatic feeding detection, can compress bale automatically.

* The baling length can be set at random, and provides bundling reminder device.

* Artificial packing, pre-install strapping design, it only thread each wire or bundling rope around bale one time to complete skein, save labor.

* Block size and voltage can be customized according to customers' reasonable requirements. Bales weight depends on different materials.

* It has high strength output door, hydraulic automatic open-end door, convenient operation and safety.

* It configures with PLC program and electric button control, operated simply and equipped with automatic feeding detection, can compress bale automatically.

* The baling length can be set at random, and provides bundling reminder device.

* Artificial packing, pre-install strapping design, it only thread each wire or bundling rope around bale one time to complete skein, save labor.

* Block size and voltage can be customized according to customers' reasonable requirements. Bales weight depends on different materials.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profie

Our company was established in 1995, with more than 25 years experiences,and our machines have been exported to more than 120 countries all over the world.

Our production plant is located in Rugao city,Jiangsu province,2 hours driving from Shanghai,with an area of 33300,welcome to visit!

After sale service

Pre-Sales

*If complicated system,check at customer site and offer solution

In-Sale

Negotiating with customer and engineers for the solution

After-Sales

*Supply installation if needed

*7X24hours after-sales service

-Service phone line keep 24 hours unblocked

-Service phone line keep 24 hours unblocked

Certifications

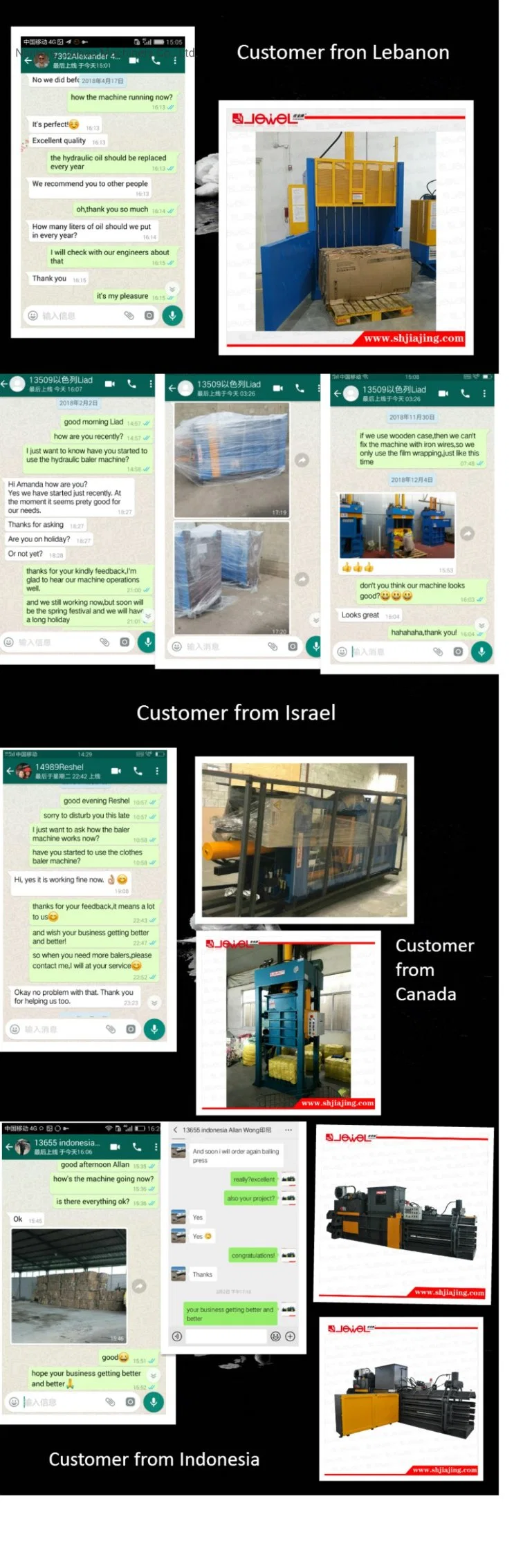

Customer feedback

Questions

What is the use of PET bottle scrap?

Discarded PET bottles are collected, sorted, cleaned, shredded, and made into 'washed flakes,' which are then used to produce a variety of products, starting from polyester fiber, which is used for a variety of applications like filling material for cushions, pillows, and converted to fabrics for use in clothing

Which is better PET or HDPE?

HDPE is a high-density plastic that is very stiff, has a good temperature resistance and a very good water vapour barrier. PET plastics are highly transparent in appearance, available in different colours, lightweight and tough against gases and liquids. PET is also highly resistant to diluted acids, oils and alcohols

What are the steps to recycle plastic bottles?

1. Step1: Collection of Waste Plastic. ...(By our hydraulic baler pressing)

2. Step2: Sorting of Plastics into Categories. ...

3. Step3: Washing to Remove Impurities. ...

4. Step4: Shredding and Resizing. ...

5. Step5: Identification and Separation of Plastics. ...

6. Step6: Compounding.

2. Step2: Sorting of Plastics into Categories. ...

3. Step3: Washing to Remove Impurities. ...

4. Step4: Shredding and Resizing. ...

5. Step5: Identification and Separation of Plastics. ...

6. Step6: Compounding.

What are the different types of plastic bottles?

Here are the six standard classifications for plastics, and the recycling and reuse information for each type.

* #1 - PET (Polyethylene Terephthalate) ...

* #2 - HDPE (High-Density Polyethylene) ...

* #3 - PVC (Polyvinyl Chloride) ...

* #4 - LDPE (Low-Density Polyethylene) ...

* #5 - PP (Polypropylene) ...

* #6 - PS (Polystyrene)

* #1 - PET (Polyethylene Terephthalate) ...

* #2 - HDPE (High-Density Polyethylene) ...

* #3 - PVC (Polyvinyl Chloride) ...

* #4 - LDPE (Low-Density Polyethylene) ...

* #5 - PP (Polypropylene) ...

* #6 - PS (Polystyrene)

Contact Information

Nantong Jiabao Machinery Co.,LTD (Factory)

Add: No.1,East Xinyuan Road,High-tech Park,Rugao,Jiangsu, China

Add: No.1,East Xinyuan Road,High-tech Park,Rugao,Jiangsu, China