- Overview

- Product Description

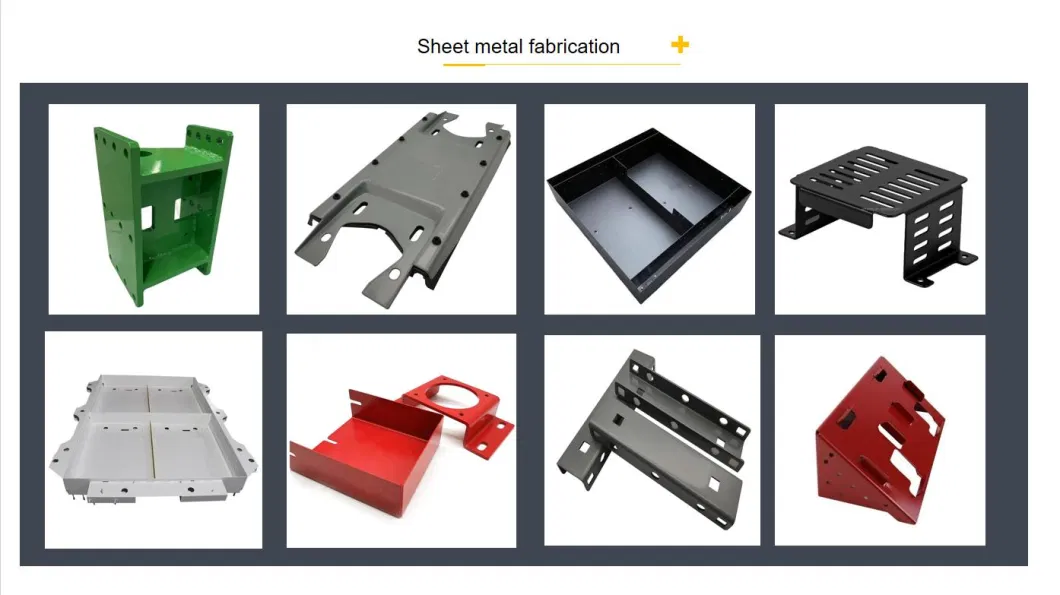

- Detailed Photos

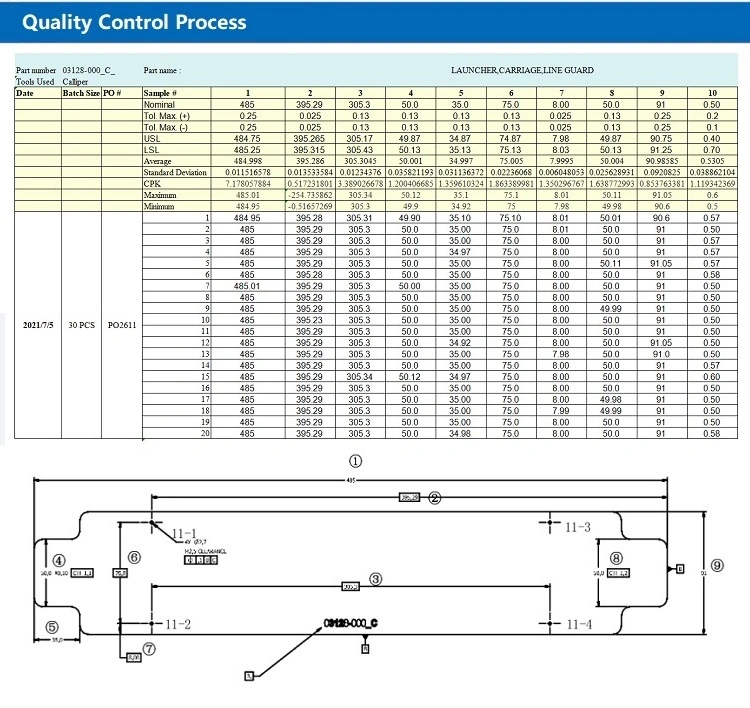

- Product Parameters

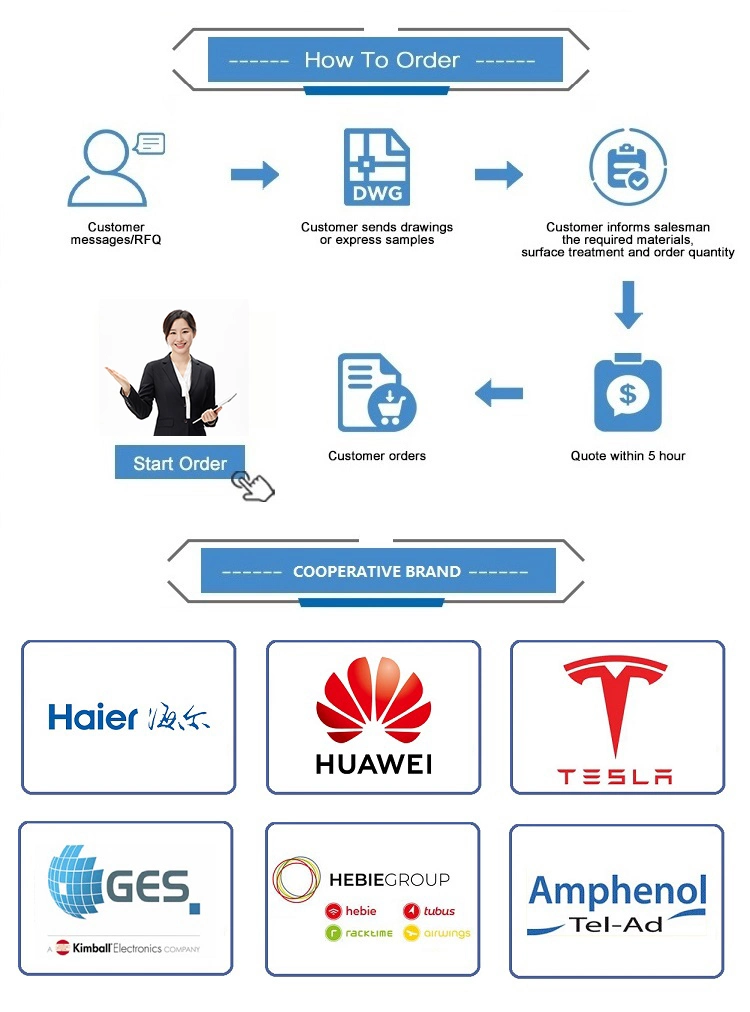

- How to order

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

| Material | Aluminum, stainless steel, copper,bronze,iron |

| Size or shape | According to customer drawings or requests |

| Service | Sheet Metal Fabrication / CNC Machining / Metal cabinets&enclosure&box / Laser Cutting Service / Steel Bracket / Stamping Parts, etc. |

| Surface treatment | Anodizing,Polishing,Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating,blacken Ect. |

| Drawing accepted | CAD, PDF, SOLIDWORKS, STP, STEP, IGS, etc. |

| MOQ | 1PCS |

| Service mode | OEM or ODM |

| Certification | ISO 9001 |

| Feature | Focus on high end market products |

| Processing procedure | Laser cutting, cnc punching, cnc bending, riveting, welding, polishing, assembly |

| Package | Inner pearl button,wooden case,or customized. |

The intricate process of creating stainless steel sheet metal parts involves several crucial steps, each requiring precision and expertise. Laser cutting, shearing, bending, and welding are the four fundamental techniques that, combined, bring these parts to life.

Laser cutting is a highly precise method that uses a focused beam of intense light to slice through metal sheets with great accuracy. This process ensures clean, smooth cuts with minimal waste. Shearing, on the other hand, is used to make straight cuts through the metal using sharp blades, which are particularly effective for thicker sheets.

Bending is a crucial step in the fabrication of sheet metal parts, as it allows for the creation of complex shapes and structures. This process involves the precise manipulation of metal sheets using presses or bending machines, ensuring that the metal is bent to the desired angle and shape without compromising its structural integrity.

Finally, welding is used to join different metal parts together, creating a strong and durable bond. This process requires skill and precision, as it involves the controlled fusion of metal at the joint, ensuring a strong and leak-proof connection.

Together, these techniques form the backbone of stainless steel sheet metal part manufacturing, allowing for the creation of precision-engineered components that are both strong and aesthetically pleasing. From automotive parts to medical equipment, the applications of these techniques are vast and diverse, underscoring the importance of precision sheet metal bending and welding in modern manufacturing.

Q: Will your company sign an NDA?

A: Yes, We will strictly follow the confidentiality agreement to protect the rights and interests of our customers

~Part size

~Design Geometry

~The number, type, and size of features

~Material(s)

~Surface finish

~Manufacturing process

Once your order is confirmed, we will review your design andprovide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It's helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. Here are some general tolerance guidelines: General tolerances for CNC machining in metal and plastic Refer to DIN ISO 2768 All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed.