- Overview

- Product Description

- Product Parameters

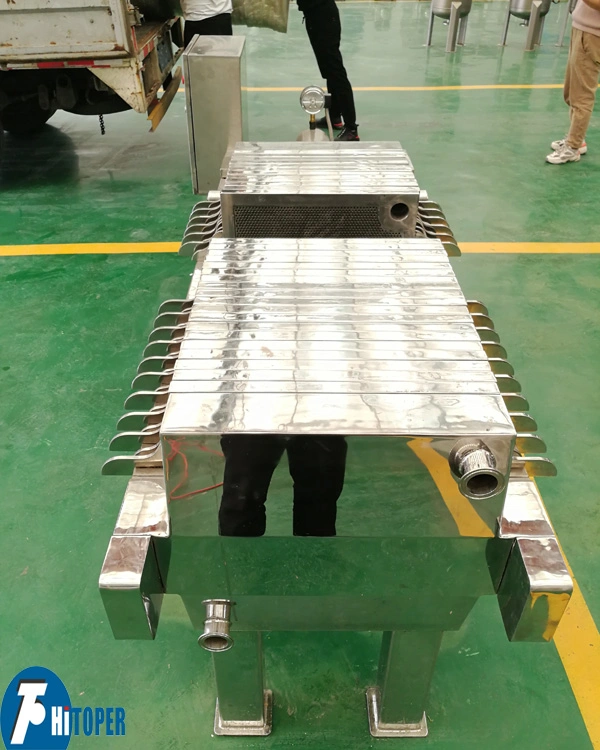

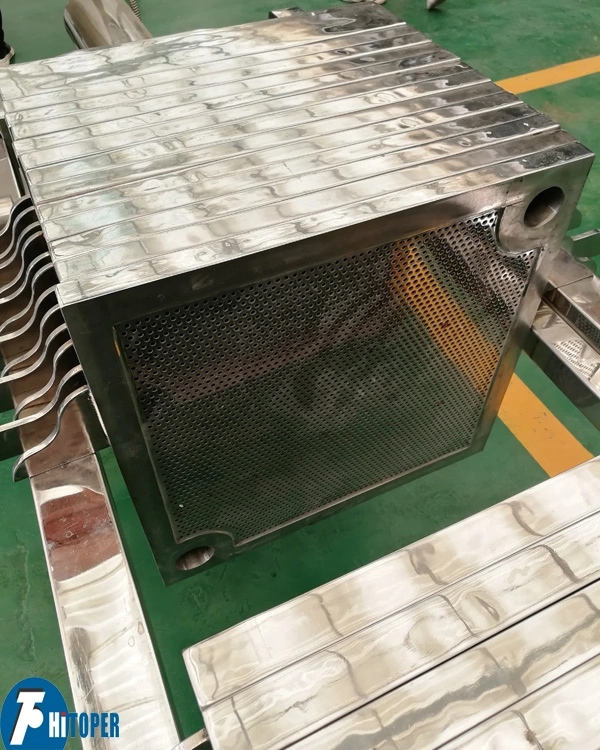

- Detailed Photos

- Company Profile

- After Sales Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Hydraulic SS304 stainless steel filter press used for food industrial

This type of food industry fine filtration stainless steel filter press ,the rack is made of carbon steel with stainless steel wraped outside,and the filter plae and frame is made of SUS 304.It is suitable for variety suspension's solid-liquid separation.Widely used in food,environment protection,light industry,medicine,chemical industry,metallurgy ,oil and other industries.

It is especially suitable for large quantities of beer ,liquid,wine,cooking oil and other liquid beverage fine filter or sterlization filter.

Operation principle :

Suspension is pumped into the filter unit with each closed filter chamber, under pressure, the filtrate through the filter layer and filter cloth, filter cloth by the fluid discharge port, the residues were kept in the filter box to achieve the solid-liquid separation purpose.

With this oil filter press machine you can choose other automatic device.

1. Automatic filter cloth varicose device, that is with some viscosity slurry, this device we design can change angle of the filter cloth into V shape, at the same time, the spring conned with vloth vibrates and the filter caks fall off.

2. Automatic bomb door. When filtration process, due to capollary leakage of cloth, there maybe a drip between the filter plates, so not only causing environmental pollution, but also increasing the moisture content of the mud, our design bomb door can collect leakage, then avoid pollution contamination of the filter press work site.

3. Belt conveyor, it can help to collect the cake and delivery to the place you prefet to.

4. Sludge storage bucket. After filtration, the filter cake canbe unloaded down to the matching sludge storage bucket, easy to focus on shipping.

SPECIFICATIONS OF MEMBRANE FILTER PRESS MACHINE

| Type | Filter area (m2) | Plate size (mm) | Cake thickness (mm) | Filter chamber volume (L) | Number of plate (pcs) | Number of frame (pcs) | Pressure (MPa) | Weight (kg) | Dimensions (mm) (L x W x H) |

| BAQ1/320 | 1 | 320 x 320 | 25 | 13 | 4 | 5 | 1.0 | 300 | 1050x700x680 |

| BAQ2/320 | 2 | 25 | 9 | 10 | 440 | 1405x700x680 | |||

| BAQ3/320 | 3 | 38 | 14 | 15 | 600 | 1650x700x680 | |||

| BAQ4/450 | 4 | 450 x 450 | 51 | 9 | 10 | 0.8 | 780 | 1680x880x900 | |

| BAQ6/450 | 6 | 76 | 14 | 15 | 995 | 1980x880x900 | |||

| BAQ8/450 | 8 | 102 | 19 | 20 | 1250 | 2180x880x900 | |||

| BAQ10/450 | 10 | 122 | 24 | 25 | 1470 | 2430x880x900 | |||

| BAQ12/450 | 12 | 152 | 29 | 30 | 1700 | 2680x880x900 | |||

| BAQ16/450 | 16 | 203 | 39 | 40 | 2170 | 3180x880x900 | |||

| BAY4/450 | 4 | 51 | 9 | 10 | 850 | 2030x880x900 | |||

| BAY6/450 | 6 | 76 | 14 | 15 | 1070 | 2280x880x900 | |||

| BAY8/450 | 8 | 102 | 19 | 20 | 1950 | 2530x880x900 | |||

| BAY10/450 | 10 | 122 | 24 | 25 | 2170 | 2780x880x900 | |||

| BAY12/450 | 12 | 152 | 29 | 30 | 2400 | 3030x880x900 | |||

| BAY16/450 | 16 | 203 | 39 | 40 | 2870 | 3530×880×900 | |||

| BAQ10/610 | 10 | 610 x 610 | 122 | 15 | 16 | 0.6 | 2030 | 2180x950x1010 | |

| BAQ12/610 | 12 | 152 | 19 | 20 | 2290 | 2380x950x1010 | |||

| BAQ15/610 | 15 | 189 | 24 | 25 | 2610 | 2630x950x1010 | |||

| BAQ20/610 | 20 | 250 | 32 | 33 | 3120 | 3030x950x1010 | |||

| BAY10/610 | 10 | 122 | 15 | 16 | 2730 | 2230x950x1010 | |||

| BAY12/610 | 12 | 152 | 19 | 20 | 2990 | 2430x950x1010 | |||

| BAY15/610 | 15 | 189 | 24 | 25 | 3310 | 2680x950x1010 | |||

| BAY20/610 | 20 | 250 | 32 | 33 | 3820 | 3080x950x1010 | |||

| BAQ15/630 | 15 | 630 x 630 | 189 | 18 | 19 | 2620 | 2325x950x1010 | ||

| BAQ20/630 | 20 | 250 | 24 | 25 | 3100 | 2630x950x1010 | |||

| BAQ30/630 | 30 | 377 | 37 | 38 | 4130 | 3280x950x1010 | |||

| BAY15/630 | 15 | 189 | 18 | 19 | 2870 | 2630x950x1010 | |||

| BAY20/630 | 20 | 250 | 24 | 25 | 3950 | 2930x950x1010 | |||

| BAY30/630 | 30 | 377 | 37 | 38 | 4980 | 3580x950x1010 | |||

| BAY30/800 | 30 | 800 x 800 | 442 | 22 | 23 | 5710 | 3150x1300x1300 | ||

| BAY40/800 | 40 | 595 | 30 | 31 | 7126 | 3630x1300x1300 | |||

| BAY50/800 | 50 | 748 | 38 | 39 | 8543 | 4100x1300x1300 |

Zhengzhou Toper is the leading supplier of industrial equipment in China, and also the professional exporter and service provider of filter and separation equipment. Also, we focus on full service for filtering project from design to after-sales service and fast supply of spare parts.

Since 2006, Zhengzhou Toper has supplied products and service to over 200 enterprises of 30 more countries and areas excluding China mainland. Southeast Asia: Indonesia, Malaysia, the Philippines, and Thailand; West Asia: Turkey, Uzbekistan and Tajikistan; Northeast Asia: Mongolia; Middle East: Israeli, Palestinian, Oman, Bahrain; Europe: Russia, Italy, Spain, Ukraine, Finland, Poland, Romania; North America: Canada, America; South America: Mexico, Guatemala, Argentina, Brazil, Chile, Peru, Bolivia; Africa: South Africa, Algeria and so on.

Our products scope is as followings,

Full automatic filter press, membrane filter press, mechanical compress filter press, jack compress filter pres, cast iron plate and frame filter press, stainless steel filter press, round filter press, belt filter press, SS centrifuge, decanter centrifuge, tubular centrifuge, vacuum disc filter, filter cloth, filter plates and so on.

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

2.Training periodically high qualified service technicians.

In-sales Service

1.Proposing the ideal scheme and equipment for our clients;

2.Designing and fabricating targeted products according to the special requirements of clients;

After-sales Service

1.Highly responsible in inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3.Assisting our clients in work site preparation for equipments;

4.Dispatching engineers to install and debug equipments;

5.Training the first-line operators on site;

6.Regularly contact clients to solve production problems;

7.Providing life-long maintenance service;

8.Providing technical exchanging;

Q1: What is the Warranty for the machines?

A1: 12 months for free.

Q2: When can I get the price?

A2: Within 24 hours, if urgent, please directly call us.

Q3: Whether the machine price can be more discount?

A3: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our Manager to appropriately give you a little discount.

Q4: How to ask quotation?

A4: Please directly tell us which item you are interested in, or note us what tpye of materials, and how many tons of materials you want to treat per day or per hour, then we will send you quotation as soon as we can.

Q5: How long will it take to receive my products?

A5: As a general rule, it will take one 15-30 days for us to produce.