Basic Info.

Model NO.

GS330

Horizontal Band Sawing Machine Type

Double Column

Saw Feed Direction

Horizontal

Track

Linear

Controlling Mode

Fully Automatic

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Weight

1600kg

Maximum Cutting Capacity

330mm( W) X 330mm( H)

Application

Metal Iron Steel Cutting

Saw Blade Specification

4115X34X1.1mm

After Sale Service

Video Training, Field Installation and Debugging

Saw Blade Tension

Manual

Work Piece Clamping

Hydraulic

Color

White, Red and Customized

Transport Package

Wood Packing

Specification

2100x2000x1750mm

Trademark

Jinfeng

Origin

Shandong China

HS Code

8461500090

Production Capacity

30 Sets/Month

Packaging & Delivery

Package Size

230.00cm * 220.00cm * 1700.00cm

Package Gross Weight

2020.000kg

Product Description

Semi Fully Automatic Steel Aluminum Metal Cutting Horizontal band saw machine

Brief introduction

Fully Semi Auto CNC Ferrous Non-ferrous Iron Carbon Steel Stainless steel Metal Alloy Aluminum Cutting Horizontal Vertical Circular Band Saw Sawing Machine is designed for cutting various ferrous material like carbon steel, low alloy steel, special alloy, acid resisting stainless steel, and non-ferrous material like copper,aluminum, glass fiber reinforced plastics.

Technical parameters of full automatic band saw GS330 GS400 GS500

Optional configuration

1, hydraulic band saw blade tension

2, band saw blade speed controlled by inverter

3, spiral chips removing device

4, 1m, 1.2m, 1.5m, 2m feeding stroke than standard 500mm feeding stroke. if you cut longer than 500mm, the feeding table could feed work piece one time instead of several times. this could be hydraulic driving and servo motor driving.

GS fully automatic band saw details

Main features

1, Suitable for sawing and cutting materials into same-sized in massive quantity;

2, Auto material feed, auto cut feed, auto cut;

3, Man-machine interface instead of the traditional control panel, digital way to set up the working parameters;

4, PLC programmable controller make selecting saw or cut mode easily;

5, the positioning error ≤±0.2mm;

6, Double-column and hydraulic cylinder structure greatly prolongs the service life of the machine;

7, Hydraulic control of cutting speed, step less speed regulation;

8, Stable sawing with high precision;

9, Can be customized: Automatic chip collection device; The clamping device for cutting bundles.

10, Feeding stroke is could be controlled by grating ruler or servo motor according to customer's feeding stroke request.

11, 500mm feeding stroke for standard model, if more than 500mm, could feed repeatedly.

12, longer feeding stroke could be customized, such as 1.2m, 2m, 3m feeding stroke, if cut longer than 500mm, could feed one time.

13, intergral coolant system

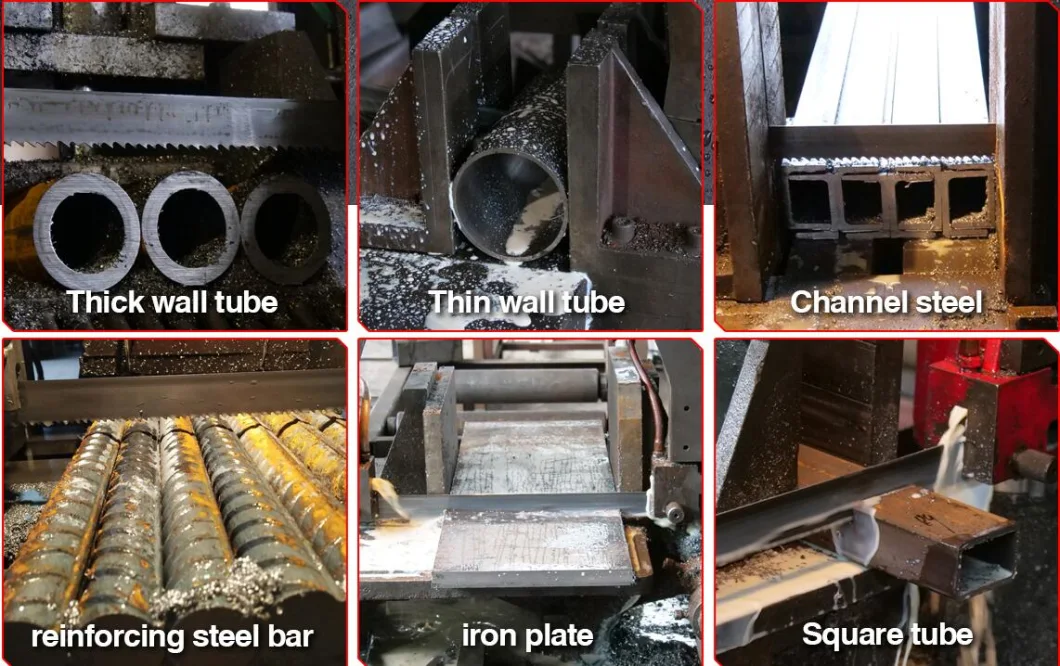

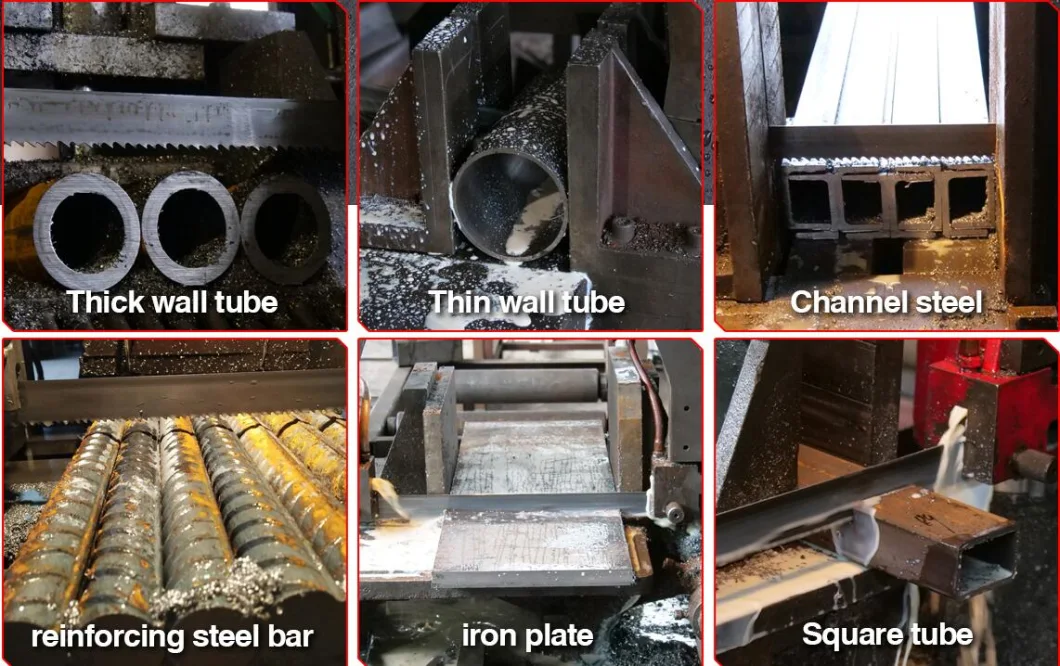

Finished cutting products

Pictures of various models of full auto cnc band saw

Our company

Jinan North Jinfeng (herein after as jinfeng) Industry Co.,LTD is specialized in manufacturing band saw machines. Founded in 1998, Jinfeng occupies 20,000 square meters plant area with more than 200 workers in which there are production department, domestic marketing department, abroad-sale department, managing department, after-sale service department, technical department and engineering department. Jinfeng was authorized ISO 9001, CE, and OHSAS18001 certificate. Jinfeng band saw machine covers series of semi automatic horizontal band saw machine, fully automatic double column band saw machine, automatic CNC band saw machine, angel band saw machine, large scale double gantry band saw machine and vertical band saw machine.

Our customers

During past 20 years, our band sawing machine is sold to more than 20 countries: Russia, Austrilia, Italy, Thailand, Indonesia, India......

Our certificate

After sale service

1, 24 hours technical center on line:

We provides our clients with 24 hours on line service for technical support. Our team have years of experience in the field.

2, video instruction for band saw installing and operating. Field training and installing is available at the request of the clients' request.

3, Guarantee time

FAQ

Q1: How to install?

A1: We adjusted machines well before we deliver. When customers receive them, you can work with them directly.

Q2: How to ensure the safety?

A2:There have the overload and over heat protection, it ensure working people safety.

Q3: How long the table saw machine can be used?

A3: It depends how you use your table saw, if use it in good maintenance, at least 8-10 years.

Q4:what is the Delivery time?

A4: Our delivery time is around 30 days. Before the machine arrive at the port, the shipping company will call you.

Q5: Are there any requirements for the dealer?

A6: There is no special conditions to be our dealer. You buy from us and sell to your customers. We introduce customers to you.

Brief introduction

Fully Semi Auto CNC Ferrous Non-ferrous Iron Carbon Steel Stainless steel Metal Alloy Aluminum Cutting Horizontal Vertical Circular Band Saw Sawing Machine is designed for cutting various ferrous material like carbon steel, low alloy steel, special alloy, acid resisting stainless steel, and non-ferrous material like copper,aluminum, glass fiber reinforced plastics.

Technical parameters of full automatic band saw GS330 GS400 GS500

| Model | GS 330 | GS 400 | GS 500 | GS600 | |

| Maximum cutting capability(mm) | Φ330mm | Φ400mm | Φ500mm | Φ600mm | |

| 330( W) x330( H) | 400( W) x 400 H | 500 (W) x 500( H) | 600 (W) x 600( H) | ||

| Bundle cutting(mm) | Maximum | 280(W)x140(H) | 300( W) x 200(H) | 500 (W) x 500( H) | 600 (W) x 600( H) |

| Minimum | 200(W)x90(H) | 200( W) x 90( H) | 300 (W) x 170( H) | 600(W)x600(H) | |

| Motor power(kw) | Main motor | 3.0kw(4.07HP) | 4.0KW(5.43HP) | 5.5KW(7.5HP) | 7.5KW(10.05HP) |

| Hydraulic pump motor | 0.75KW(1.02HP) | 0.75KW(1.02) | 1.5KW(2HP) | 1.5KW(2HP) | |

| Coolant pump motor | 0.09KW(0.12HP) | 0.09KW(O.12HP) | 0.09KW(0.12HP) | 0.125KW(0.17HP) | |

| Saw blade speed(m/min) | 40/60/80 (regulated by cone pulley) | 20-100m/min | |||

| Saw blade size(mm) | 4115x34x1.1mm | 4900x41x1.3mm | 5550x41x1.3mm | 6300x41x1.3mm | |

| Work piece clamping | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

| Saw blade tension | Manual | Manual | Hydraulic | Hydraulic | |

| Main drive | Worm gear | Worm gear | Worm gear | Worm gear | |

| Material feeding type | Roller | Roller | Roller | Roller | |

| Maximum feeding stroke | Regular model is 500mm, could customized according to the cutting length like 1m, 2m, 3m feeding stroke. | ||||

| Work table size(mm) | 650 | 650 | 650 | 650 | |

| Over size (LxWxH) | 2000x1200x1500 | 2600x1600x1650 | 2900x3000x1750 | 3500x3000x1750 | |

| Net weight(kg)(approximate) | 1500 | 1800 | 2400 | 2600 | |

1, hydraulic band saw blade tension

2, band saw blade speed controlled by inverter

3, spiral chips removing device

4, 1m, 1.2m, 1.5m, 2m feeding stroke than standard 500mm feeding stroke. if you cut longer than 500mm, the feeding table could feed work piece one time instead of several times. this could be hydraulic driving and servo motor driving.

GS fully automatic band saw details

Main features

1, Suitable for sawing and cutting materials into same-sized in massive quantity;

2, Auto material feed, auto cut feed, auto cut;

3, Man-machine interface instead of the traditional control panel, digital way to set up the working parameters;

4, PLC programmable controller make selecting saw or cut mode easily;

5, the positioning error ≤±0.2mm;

6, Double-column and hydraulic cylinder structure greatly prolongs the service life of the machine;

7, Hydraulic control of cutting speed, step less speed regulation;

8, Stable sawing with high precision;

9, Can be customized: Automatic chip collection device; The clamping device for cutting bundles.

10, Feeding stroke is could be controlled by grating ruler or servo motor according to customer's feeding stroke request.

11, 500mm feeding stroke for standard model, if more than 500mm, could feed repeatedly.

12, longer feeding stroke could be customized, such as 1.2m, 2m, 3m feeding stroke, if cut longer than 500mm, could feed one time.

13, intergral coolant system

Finished cutting products

Pictures of various models of full auto cnc band saw

Our company

Jinan North Jinfeng (herein after as jinfeng) Industry Co.,LTD is specialized in manufacturing band saw machines. Founded in 1998, Jinfeng occupies 20,000 square meters plant area with more than 200 workers in which there are production department, domestic marketing department, abroad-sale department, managing department, after-sale service department, technical department and engineering department. Jinfeng was authorized ISO 9001, CE, and OHSAS18001 certificate. Jinfeng band saw machine covers series of semi automatic horizontal band saw machine, fully automatic double column band saw machine, automatic CNC band saw machine, angel band saw machine, large scale double gantry band saw machine and vertical band saw machine.

Our customers

During past 20 years, our band sawing machine is sold to more than 20 countries: Russia, Austrilia, Italy, Thailand, Indonesia, India......

Our certificate

After sale service

1, 24 hours technical center on line:

We provides our clients with 24 hours on line service for technical support. Our team have years of experience in the field.

2, video instruction for band saw installing and operating. Field training and installing is available at the request of the clients' request.

3, Guarantee time

1) Our quality guarantee time is 12 months since the machine on board;

2) During this period, if the machine break down owing our machine itself quality problem, we will prepare the spare parts; and send to you by free within 5 days. all these will be by free.

3) If the break down is caused by improper operation, we could supply the spare parts with factory cost.

2) During this period, if the machine break down owing our machine itself quality problem, we will prepare the spare parts; and send to you by free within 5 days. all these will be by free.

3) If the break down is caused by improper operation, we could supply the spare parts with factory cost.

FAQ

Q1: How to install?

A1: We adjusted machines well before we deliver. When customers receive them, you can work with them directly.

Q2: How to ensure the safety?

A2:There have the overload and over heat protection, it ensure working people safety.

Q3: How long the table saw machine can be used?

A3: It depends how you use your table saw, if use it in good maintenance, at least 8-10 years.

Q4:what is the Delivery time?

A4: Our delivery time is around 30 days. Before the machine arrive at the port, the shipping company will call you.

Q5: Are there any requirements for the dealer?

A6: There is no special conditions to be our dealer. You buy from us and sell to your customers. We introduce customers to you.