- Overview

- Product Description

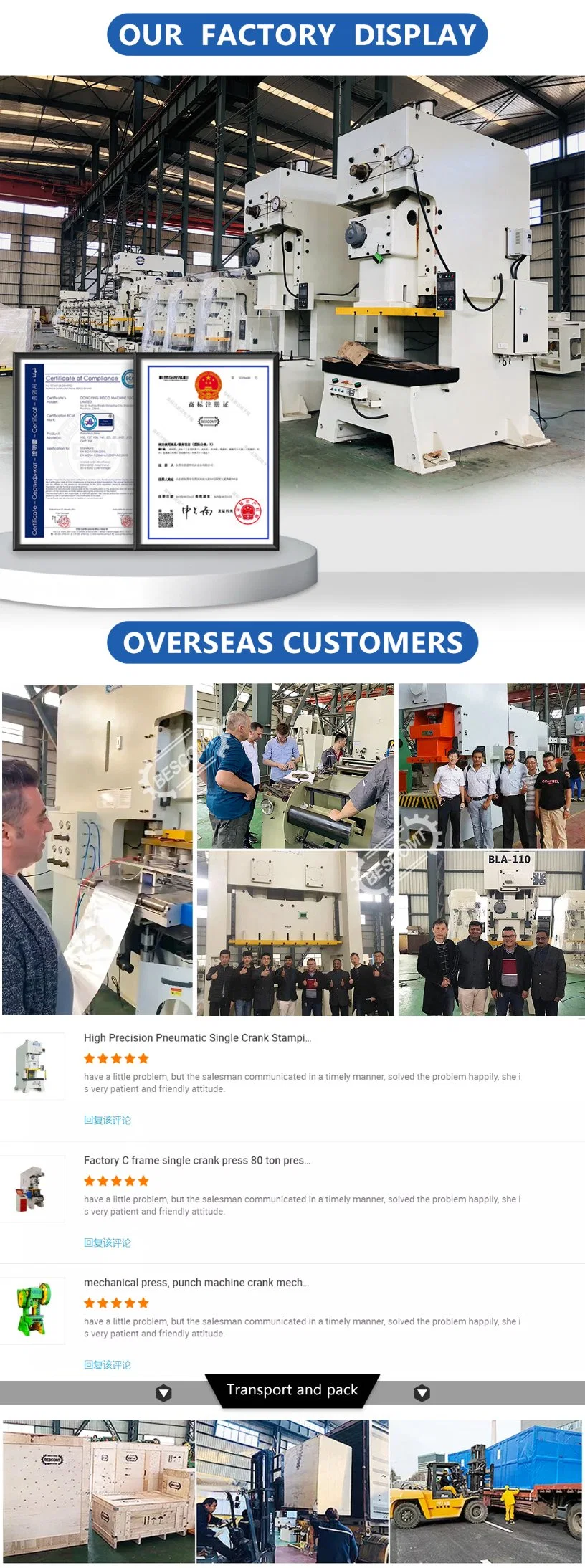

- Company Profile

- After Sales Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Deeping Drawing Hydraulic Press Machine

This four-column hydraulic press is computer-optimized and designed with a four-column structure that is simple, economical and

practical.The frame-type structure has good rigidity,high precision,and strong anti-unbalanced load capability. The hydraulic

control system adopts a cartridge-type integrated system,reliable operation and long service life.

The hydraulic impact is small, which reduces the number of connecting pipes and leakage points.The imported PLC-controlled

electrical system has a compact structure, is sensitive and reliable,and is easy to use and maintain.With adjustment,

manual,semi-automatic three operating modes and schedules, constant pressure two molding process specifications.The bottom beam is

equipped with a hydraulic pad. Through the operation panel selection, the hydraulic pad can achieve three working cycles of top

ejection, no ejection, and hydraulic pressure pad pressing

Technical Parameter

| Item | Unit | Y32-40 | Y32-63 | Y32-100 | Y32-125 | Y32-160 | Y32-200 | Y32-250 | |

| Norminal pressure | KN | 400 | 630 | 1000 | 1250 | 1600 | 2000 | 2500 | |

| Knock out force | KN | 63 | 100 | 190 | 200 | 250 | 400 | 450 | |

| Ram stroke length | mm | 350 | 450 | 500 | 550 | 580 | 710 | 710 | |

| Knock out stroke | mm | 120 | 160 | 200 | 200 | 200 | 200 | 200 | |

| Max.opening height | mm | 600 | 700 | 800 | 900 | 900 | 1120 | 1120 | |

| Slide stroke speed | Down speed | mm/s | 40 | 100 | 100 | 120 | 100 | 120 | 130 |

| Work speed | mm/s | 10-20 | 8-16 | 8-15 | 7-15 | 4-10 | 5-12 | 4-10 | |

| Return speed | mm/s | 100 | 85 | 85 | 90 | 70 | 95 | 60 | |

| Knock out speed | Knock out | mm/s | 60 | 55 | 60 | 75 | 75 | 80 | 80 |

| Return | mm/s | 95 | 105 | 100 | 140 | 140 | 145 | 145 | |

| Table size | L-R | mm | 450 | 580 | 710 | 750 | 780 | 1000 | 1120 |

| F-B | mm | 450 | 500 | 580 | 600 | 680 | 940 | 1000 | |

| Dimension | L-R | mm | 1350 | 1900 | 2076 | 2500 | 2550 | 2650 | 2800 |

| F-B | mm | 1050 | 1100 | 1200 | 1430 | 1600 | 2150 | 2280 | |

| Height | mm | 2350 | 2450 | 3300 | 3350 | 3350 | 3800 | 3950 | |

| General Power | KW | 4 | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 | |

| Machine weight | Kg | 2850 | 3500 | 5500 | 6500 | 7650 | 9500 | 13000 | |

Applied products

And all the times our company put the machine quality at the first position, focus on the machine development and update, which

keep our company have a fast development speed and get good reputation from customers. Our long-term cooperation company

include:Foxconn, NK car, China Aluminum Group, Fangyuan Group, Tianrun Crankshaft, Konka, etc. Our company make

"satisfy the customers" as our target, hope to create the best future with old and new customers.

We are currently reviewing our product packaging from the angles of waste-reduction and resource-saving. We are also working on improving transportation efficiency from the design phase of product development.

We are currently reviewing our product packaging from the angles of waste-reduction and resource-saving. We are also working on improving transportation efficiency from the design phase of product development. 1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time.

2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork.

4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

customer.

2.We can send the component by DHL, TNT freely

3.Our factory can send our engineer to the customer's factory install, commission and training freely

our factory to learn the operation and maintains freely.

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance before delivery

3.Guaranty covers?

Main parts of the machine , wearing parts not included .PARTS DELIVERY. Within 5 days by DHL / Fexed .

4.About our after-sale service:

Customer service 24 hours online, you can send technicians to your country to repair the machine. Buyer shall bear all costs including visa, round trip airfare and suitable accommodation and buyer shall pay usd 100 / day salary.

5.How to replace machine parts?

Parts adopt international brands, good quality, no need to replace within 3-5 years, convenient to buy suitable parts locally.

6.Installation&Commissioning:

Usually solved by video conference, if necessary, can be dispatched to the door installation debugging and maintenance of technical personnel.