Basic Info.

Model NO.

YHA3-300T

Voltage

380V/220V Optional

Power

16.4kw

Weight

4.5ton

After-Sales Service

Engineers Available to Service Machinery Overseas

Function

Cold Forging Press

Usage

LED Heat Sink; Gear; Universal Joint

Surface

Hard Chrome Plated

Structure

Four Column

Motor System

Servo Motor

Main Components

Imported From Famous Brand

Application

Metal Sheet Stamping

Technology

Cold Forging

Type

Four-Column Hydraulic Press

Certification

ISO9001, CE, SGS; BV

Transport Package

Wooden Box Package

Specification

300 ton

Trademark

YIHUI

Origin

Guangdong, China(Mainland)

HS Code

8462919000

Production Capacity

35 Sets Per Month

Product Description

300 ton to 1500 ton Forging Hydraulic Press for Auto Parts Making

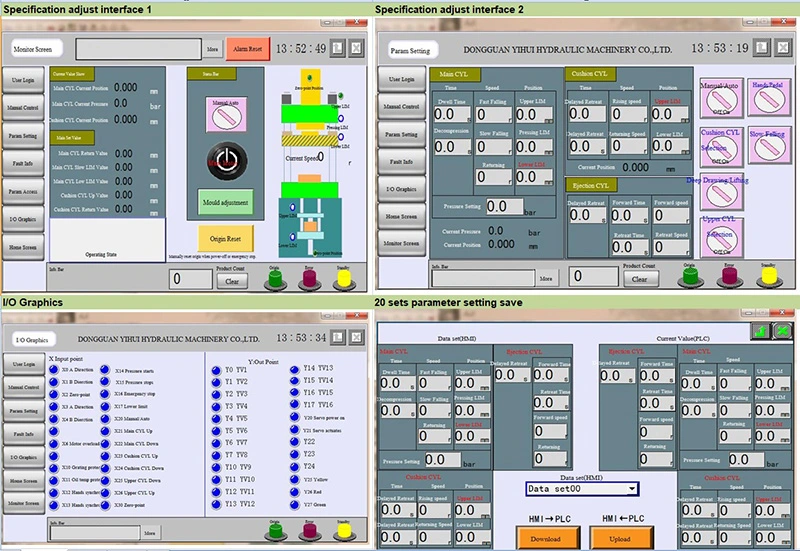

Touch Screen

Main Features

1. Reasonable design and good processing part make it low energry consumption.

2. Cylinder adopts to forge and grind, it have good reliability in state of high pressure.

3. Many kinds working speed improve the efficiency of production.

4. Run steady,low noise, with electric eye for worker safety.

5. Easy to set with machine by PLC and touch screen.

6. Pressure adjustable in big range for different need.

7. Frame and active beam have high guide precision, rigidity and hardwearing,

especially are suitable for pressing anisomerous parts.

2. Cylinder adopts to forge and grind, it have good reliability in state of high pressure.

3. Many kinds working speed improve the efficiency of production.

4. Run steady,low noise, with electric eye for worker safety.

5. Easy to set with machine by PLC and touch screen.

6. Pressure adjustable in big range for different need.

7. Frame and active beam have high guide precision, rigidity and hardwearing,

especially are suitable for pressing anisomerous parts.

Our factory can customize hydraulic press machine according to your needs.

| Item | Unit | YHA3-300ton | YHA3-500ton | YHA3-650ton | YHA3-800ton | YHA3-1000ton | YHA3-1500ton | |

| Nominal Capacity | kN | 3000 | 5000 | 6500 | 8000 | 10000 | 15000 | |

| Max. Working Pressure | Mpa | 24 | 25 | 25 | 24 | 24 | 24 | |

| Main Cylinder Stroke | kN | 3000 | 5000 | 6500 | 8000 | 10000 | 15000 | |

| Max. Stroke Of Ram | mm | 350 | 350 | 500 | 500 | 500 | 500 | |

| Max. Open Height | mm | 700 | 900 | 1000 | 1000 | 1200 | 1400 | |

| Lower Cylinder Capacity | kN | 300 | 400 | 500 | 500 | 500 | 600 | |

| Max.Stroke Of Cushion Piston | mm | 200 | 200 | 200 | 200 | 200 | 200 | |

Speed Of Ram | Down No Load | mm/s | 260 | 250 | 210 | 200 | 190 | 190 |

| Pressing | mm/s | 8/15 | 8/15 | 8/16 | 8/16 | 8/16 | 7/9 | |

| Return | mm/s | 230 | 230 | 200 | 190 | 180 | 180 | |

| Effective Area Of Working Table | RL(column inside) | mm | 550 | 650 | 750 | 850 | 1000 | 1200 |

| FB(edge) | mm | 650 | 700 | 800 | 950 | 1060 | 1400 | |

Overall Dimension | L.R | mm | 2150 | 2250 | 2370 | 2550 | 2950 | 3500 |

| F.B | mm | 1550 | 1850 | 1800 | 1850 | 2200 | 2400 | |

| H | mm | 3020 | 3550 | 3700 | 3950 | 4100 | 5250 | |

| Motor Power | kW | 15 | 18+11 | 22+22 | 22+30 | 22+30 | 30+30 | |

| Total Weight(Approx) | Ton | 4.5 | 7.8 | 11.5 | 13.5 | 21 | 25 | |

| Oil Quantity(Approx) | L | 450 | 500 | 800 | 800 | 1000 | 1300 | |

YIHUI Hydraulic press with servo system,can bring you 10 kinds advantages as below:

1.Can avoid the oil leakage. Because using Servo motor, the oil temperature can be lower.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% - 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

2.English and customer country local language, bilingual operation interface, easy to operate.

3.Can save 50% - 70% electricity energy.

4.Parameters and Speed can be adjusted on the touch screen, easy to operate.

(Machine without servo system, speed can not been adjusted.)

5.Can be 3 to 5 years longer service life than the common machine.

It means,if common machine can service for 10 years, then machine with servo, can use 15 years.

6.Ensure safety and easy to know error,easy to do after service.

Because of Automatic alarm and auto troubleshooting system.

7.Very easy to change mold, shorter time of changing mold.

Because it have memory function,if use the original mold, do not need to adjust parameter again,

8.Very quiet , do not have noise.

9.Much stable than common machine.

10.Much high precision than common machine.

Dongguan Yihui Hydraulic Machinery Co., Ltd.

We have been specialized in manufacturing hydraulic press machine for over 20 years .

YIHUI brand machines have been exported to over 30 countries,

such as Germany, USA, UK, Sweden, Japan,Slovenia, Saudi Arabia,El Salvador,Togo,Malaysia,Singapore, Australia ,

Vietnam,Pakistan,South Africa, and so on.

Especially speciallized in the servo system hydraulic press machine .

Welcome to visit our factory!

Q1. Are you manufacturer or trader?

A: We have been specialized in manufacturing hydraulic press machine for over 20 years.

We have our R&D team, experienced engineers and professional sales team.

Q2. What is your terms of payment?

A: T/T 50% as deposit, full payment before shipping. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your trade terms?

A: EXW, FOB, CIF and CFR are all acceptable.

Q4. How about your delivery time?

A: Generally, it will take 35 working days after receiving your deposit payment.

The specific delivery time depends on the items and the quantity of your order.

Sometimes we have standard machines in stock.

Q5. What is your warranty policy?

A:We can supply 12 months warranty for our machines.

We can send engineer to customer place if big quality problem.

We can provide internet or calling service at any time.

Q6. What is the after-sales service of your factory?

A: We can offer engineer to adjust machine and training in your company.

Engineers overseas assemble, testing machine and training are available.

Q7. How to use your products?

A: Welcome to our factory to learn how to operate our machine,

we will give good training our engineer is available for user. If there is requirement,

our engineer can go to user factory, and adjust machine, give good training to user .

Q8. How does your factory do regarding quality control?

A: Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end.

We have ISO and CE certification approval.

Q9. What is the advantage of your factory?

A: The main components of our machine are imported from the famous brand such as Japan and Germany.

So the quality is near the Japan production, but the unit price is lower than it.

Also we can offer full set line service, such as the mould, process technology, and other relative machines.

In other words, all you need to do is provide the drawings of the product and we can design the whole line solution for you.

YIHUI brand machines have been exported to over 30 countries,

such as Germany, USA, UK, Sweden, Japan,Slovenia, Saudi Arabia,El Salvador,Togo,Malaysia,Singapore, Australia ,

Vietnam,Pakistan,South Africa, and so on.

Especially speciallized in the servo system hydraulic press machine .

Welcome to visit our factory!

Q1. Are you manufacturer or trader?

A: We have been specialized in manufacturing hydraulic press machine for over 20 years.

We have our R&D team, experienced engineers and professional sales team.

Q2. What is your terms of payment?

A: T/T 50% as deposit, full payment before shipping. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your trade terms?

A: EXW, FOB, CIF and CFR are all acceptable.

Q4. How about your delivery time?

A: Generally, it will take 35 working days after receiving your deposit payment.

The specific delivery time depends on the items and the quantity of your order.

Sometimes we have standard machines in stock.

Q5. What is your warranty policy?

A:We can supply 12 months warranty for our machines.

We can send engineer to customer place if big quality problem.

We can provide internet or calling service at any time.

Q6. What is the after-sales service of your factory?

A: We can offer engineer to adjust machine and training in your company.

Engineers overseas assemble, testing machine and training are available.

Q7. How to use your products?

A: Welcome to our factory to learn how to operate our machine,

we will give good training our engineer is available for user. If there is requirement,

our engineer can go to user factory, and adjust machine, give good training to user .

Q8. How does your factory do regarding quality control?

A: Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end.

We have ISO and CE certification approval.

Q9. What is the advantage of your factory?

A: The main components of our machine are imported from the famous brand such as Japan and Germany.

So the quality is near the Japan production, but the unit price is lower than it.

Also we can offer full set line service, such as the mould, process technology, and other relative machines.

In other words, all you need to do is provide the drawings of the product and we can design the whole line solution for you.