Basic Info.

Product Description

1. Hydraulic System:

The hydraulic system device is arranged on the right side of the fuselage, with cartridge integrated system, flexible action, reliable work, good sealing performance. The hydraulic pump comprises an oil tank, a high-pressure pump, motor, cartridge valves and other components, the tank is welded with steel plates, the tank using sealed oil tank, oil zone and back to oil tank is provided with aspartate, cleaning windows and oil drain plug, so that the cleaning and changing is convenient. Oil pump suction mouth check formula oil suction filter, ensure that the oil cleanliness, to ensure the service life of the pump and valve.

Hydraulic system of reliable sealing, no leakage; the main pipe flange connection, the pipeline is provided with anti-vibration facilities (seismic pipe clamp).

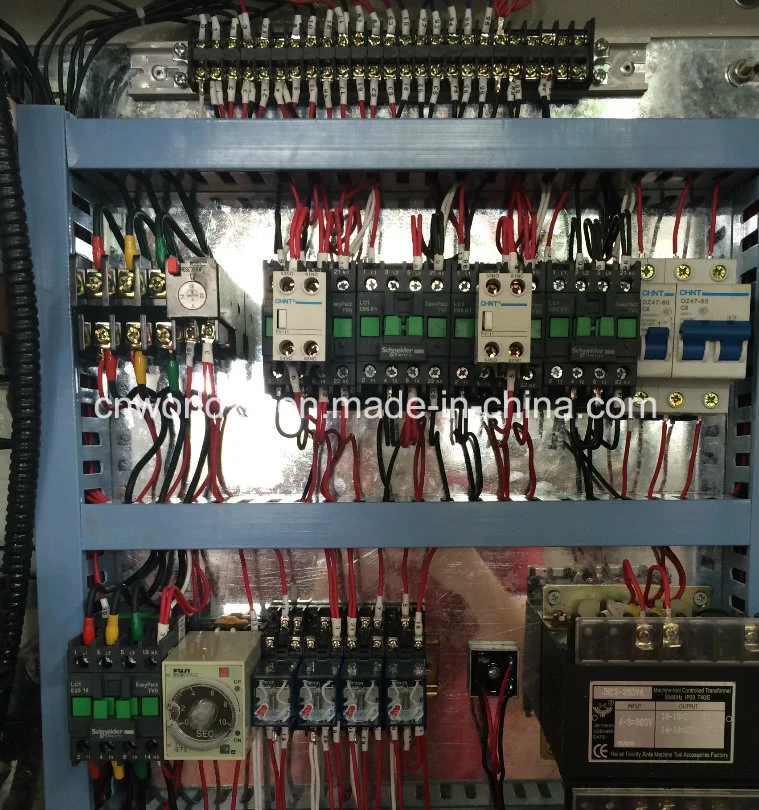

2.Electrical Control System:

Electrical cabinet is provided with an independent cabinet, and provided with an air switch, relay and other electrical appliances, all kinds of alarm signal of compressor, limit switch and press action to achieve the action chain. With a centralized control panel, panel layout action button and select switch is necessary, also, it has a mobile button station.

3.Operation:

The machine has a point of moving, semi-automatic with two kinds of mode of operation, the slider stroke by stroke control device adjusts the operating button press, in addition to the completion of action on the table, there are also "hands pressing", "return", "stop", "emergency stop" button on the machine.

Specifications:

| Model | Unit | Y41-25 | Y41-40 | Y41-63 | Y41-100 | Y41-160 | Y41-200 | |

| Nominal Force | kN | 250 | 400 | 630 | 1000 | 1600 | 2000 | |

| Working table height | mm | 710 | 710 | 810 | 800 | 830 | 900 | |

| Max.hydraulic pressure | MPa | 16 | 25 | 25 | 25 | 25 | 25 | |

| Throat depth | mm | 350 | 350 | 320 | 400 | 420 | 450 | |

| Stroke of slide | mm | 400 | 400 | 500 | 600 | 700 | 700 | |

| Daylight | mm | 630 | 630 | 750 | 800 | 900 | 1000 | |

| Speed of slide | idle | mm/s | 80 | 80 | 120 | 100 | 80 | 80 |

| pressing | mm/s | 18-20 | 18-20 | 18-20 | 15-20 | 10-15 | 10-15 | |

| return | mm/s | 75 | 75 | 100 | 100 | 70 | 70 | |

| Effective area of work table | L-R | mm | 580 | 700 | 710 | 800 | 900 | 900 |

| F-B | mm | 570 | 570 | 600 | 700 | 800 | 800 | |

| Motor Power | KW | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 15 | |